Cyclic utilization method for cotton fabric degreasing and bleaching solution and device thereof

A cotton fabric debleaching technology, which is applied in the field of cotton fabric debleaching process, can solve the problems of non-recycled utilization and increase the burden of sewage treatment system, and achieve the goal of realizing recycling, reducing energy consumption, reducing consumption and emission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

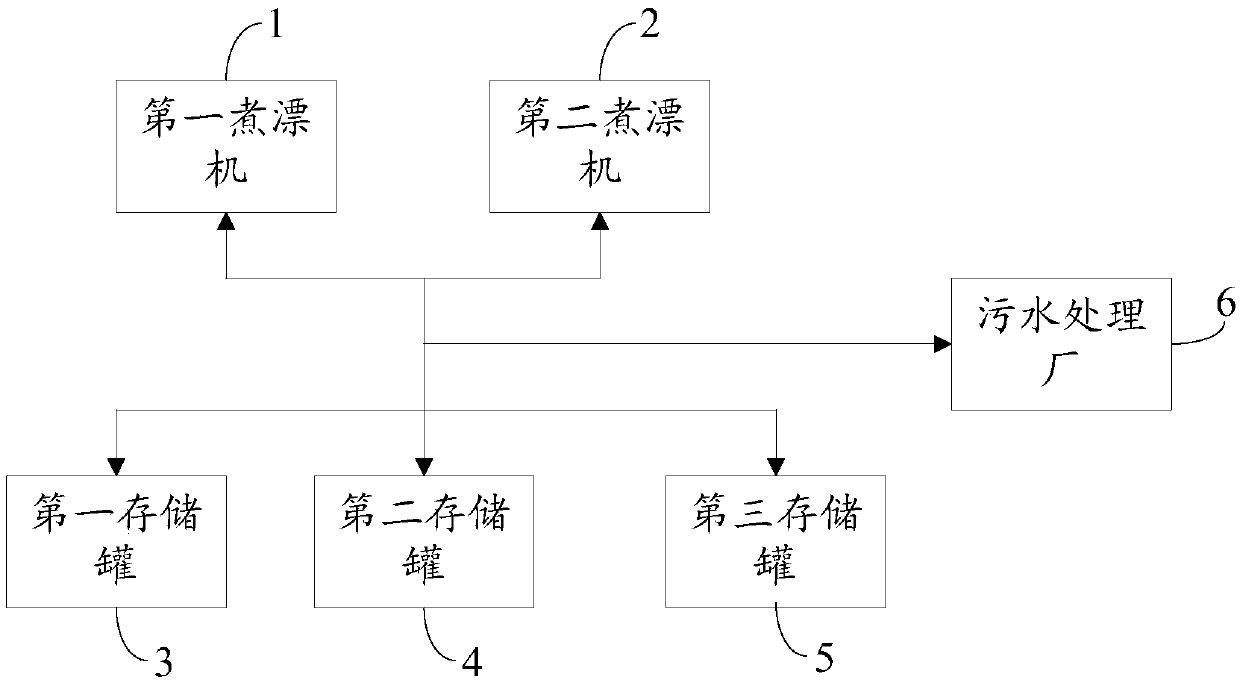

Image

Examples

Embodiment 1

[0022] This embodiment provides a method for recycling the debleaching liquid of cotton fabrics. This method is mainly aimed at recycling the three kinds of water (boiling and bleaching high temperature water, warm water and normal temperature water) in the degreasing and bleaching process of cotton fabrics.

[0023] Specific steps are as follows:

[0024] (1) Recycling and use of high-temperature boiling water: the high-temperature water degreased and bleached in the first boiling and bleaching machine is introduced into the second boiling and bleaching machine through the drive pump, and the second cooking and bleaching machine is in the state of waiting for cooking and bleaching; After the second scouring and bleaching machine is introduced into high-temperature water, add 10%-20% of fresh water, for example, add 15% of fresh water; after the temperature in the pot of the second scouring and bleaching machine drops to 70-80°C, add chemical additives. Chemical additives main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com