Circuit board, circuit board manufacturing method, electronic device and assembly method thereof

A technology for electronic equipment and circuit boards, which is applied in printed circuit components, structural connection of printed circuits, printed circuit assembly of electrical components, etc. It can solve problems such as FPC offset production and defects, and achieve accurate alignment work and save energy. Production cost and the effect of improving placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

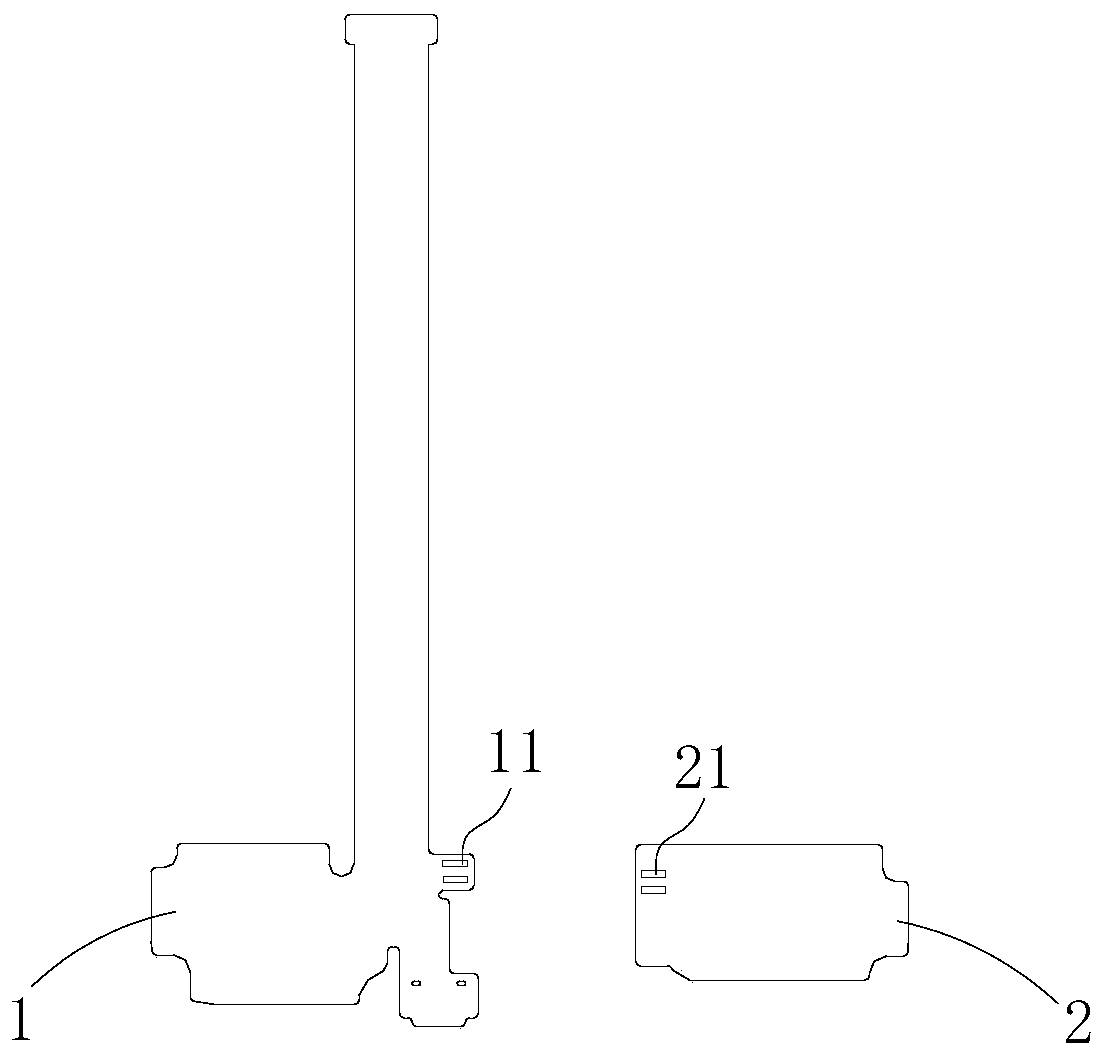

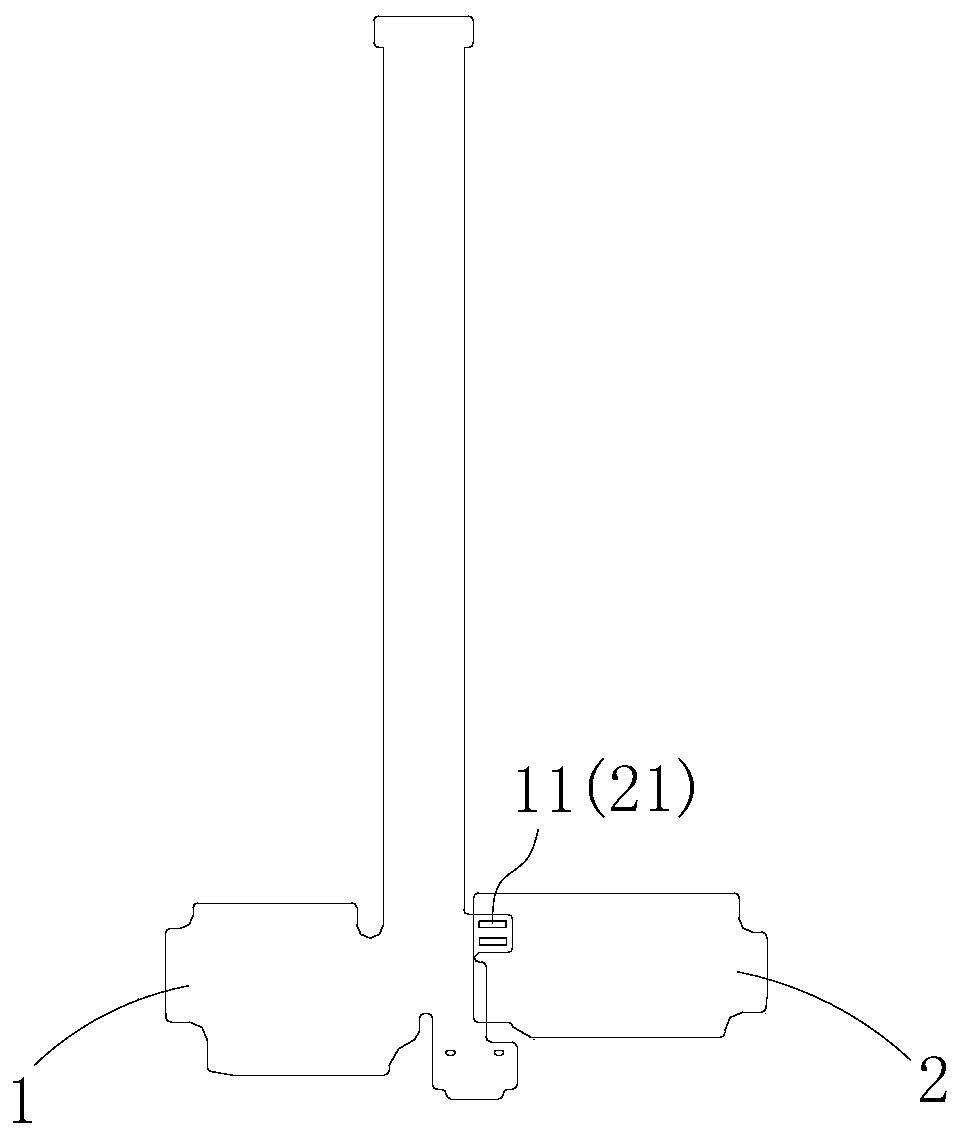

[0045] See figure 1 and figure 2 , the present embodiment provides a circuit board, which includes a main board 1 and a sub-board 2, the main board 1 and the sub-board 2 are provided with splicing parts, and the splicing parts of the two are respectively provided with a splicing pad 11 and a splicing pad 21 , the splicing part of the sub-board 2 and the splicing part of the main board 1 are welded together through the splicing pad 11 and the splicing pad 21 .

[0046] Specifically, the main board 1 is a main circuit board, and the sub-board 2 is a speaker circuit board. In this embodiment, all the main boards 1 and sub-boards 2 are flexible circuit boards; the speaker circuit board and the main circuit board together form a T-shape, wherein the main circuit board is L-shaped. The splicing parts of the main board 1 and sub-board 2 are stacked up and down, the splicing pads 11 and the splicing pads 21 are aligned up and down, and are fixed by solder paste welding.

[0047] T...

Embodiment 2

[0061] This embodiment provides another manufacturing method for the circuit board in Embodiment 1, including the following steps:

[0062] S30. Analyze the shape of the circuit board, define the part protruding from one side of the middle area of the circuit board as sub-board 2, and define the common board formed by the middle area of the circuit board and the part protruding from the other side of the middle area For motherboard 1.

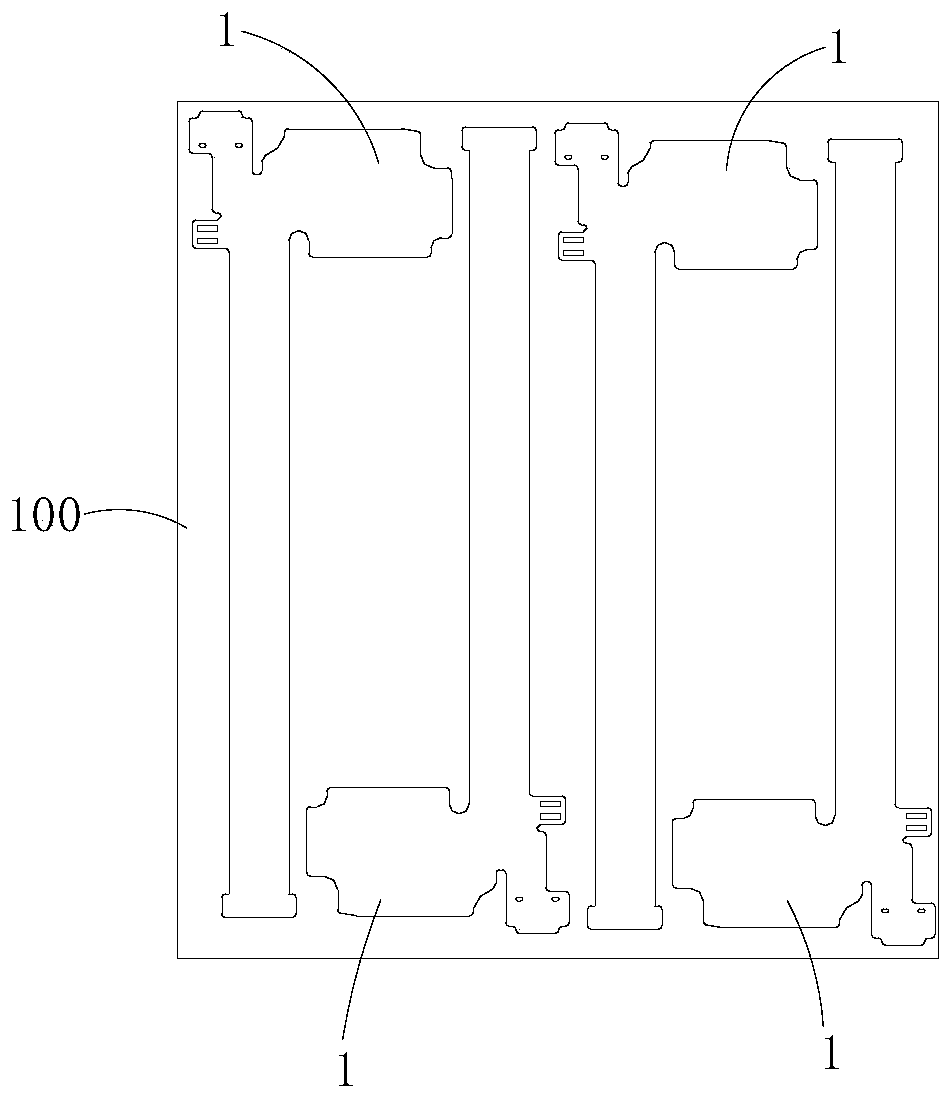

[0063] S31. Divide a circuit board into a main board 1 and sub-boards 2, so that the main board 1 has a larger end and a smaller end, and design splicing pads 11, Stitching pad 12;

[0064] S32. See Image 6 , at least two main boards 1 are laid out on one imposition 400, and, among two adjacent main boards 1, the larger end of one main board 1 corresponds to the smaller end of the other main board 1, and the sub-boards 2 are arranged on the same On the imposition 400, and the position of the sub-board 2 layout is located in the gap betw...

Embodiment 3

[0070] This embodiment provides another method for making a circuit board, including the following steps:

[0071] S40, see Figure 7a , a circuit board is divided into a main board 1 and two side boards 5, so that the width at both ends of the main board 1 is greater than the middle width, and the area of the two side boards 5 is smaller than the area of the main board 1,

[0072] S41, respectively designing splicing pads at the splicing places of the main board 1 and the side plates 5;

[0073] S42. See Figure 7b , at least two main boards 1 are laid out on one imposition 500, and, among two adjacent main boards 1, the two ends of the main board 1 correspond to the two ends of the other main board 1 respectively, and the side boards 5 are arranged on the same On the imposition 500, and the position of the layout of the side plate 5 is located in the gap between the two main boards 1;

[0074] S43. Paste electronic components on the imposition 500, and then pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com