Dynamic smoke treatment equipment

A technology for processing equipment and dust, which is applied in the direction of particle charging/ionization, electrode structure, electrostatic separation, etc., can solve the problems of not achieving purification effect, gas blockage, environmental damage, etc., and achieve small pressure loss, simplified structure, and wide application The effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

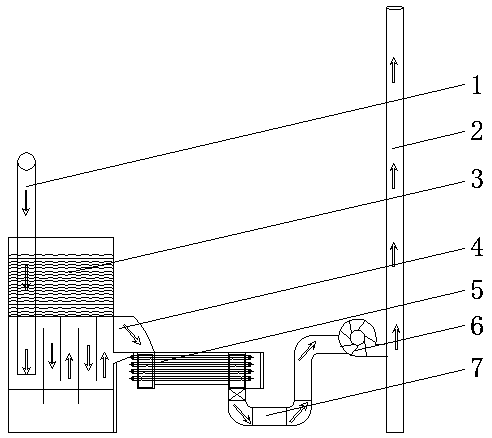

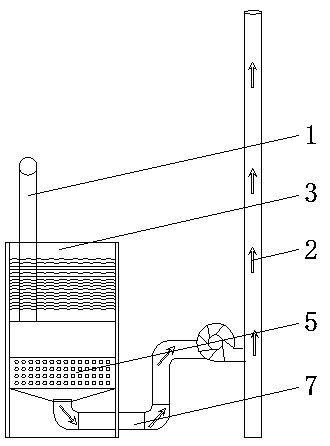

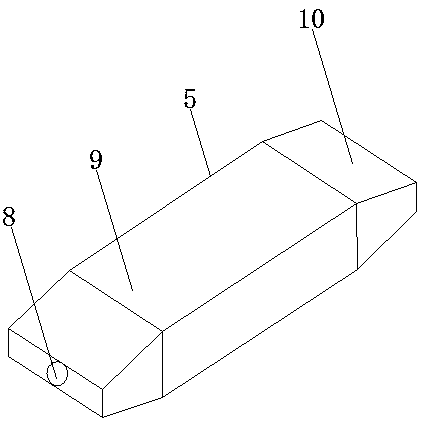

[0017] Such as Figure 1-4 Shown: dynamic soot treatment equipment, including steam outlet pipe 1, chimney 2, boiler 3, duct 4, dynamic soot adsorber 5, fan 6, U-shaped pipe 7, smoke inlet 8, shell 9, plug 10, The ion electrostatic tube 11 and the conductor 12, the upper end of the boiler 3 is provided with a steam outlet pipe 1, and the gas outlet on the side of the boiler 3 is sealed and connected with the smoke inlet 8 at one end of the smoke absorber 5 through the conduit 4, and the shell of the smoke absorber 5 There is an ion electrostatic tube 11 inside the body 9, which makes the ion electrostatic tube 11 have the adsorption capacity, so as to achieve the effect of purifying smoke and dust. Compared with other filter devices, this structure has a more efficient dust removal efficiency and will not cause gas blockage , can purify a large amount of air, save electric energy, and can remove particles with a wide range of particle sizes, and has a wide range of application...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com