A preparation method of anti-sedimentation carrier particles for food safety testing

A technology for carrier particles and food safety, applied in the field of detection, can solve the problems of ineffective amplification of reaction signals and easy occurrence of sedimentation, and achieves the effect of contributing to the reaction phenomenon, reducing the interface energy and improving the application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

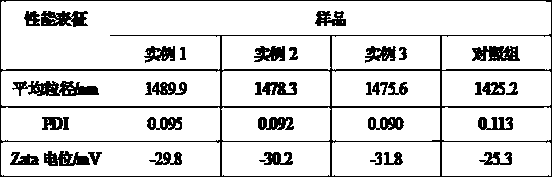

example 1

[0018] In terms of parts by weight, weigh 45 parts of n-butanol, 10 parts of cyclohexane, 3 parts of propylene glycol polyoxyethylene polyoxypropylene ether, and 55 parts of deionized water in a beaker, stir and mix, and place under 200W ultrasonic Disperse for 10 minutes to obtain a dispersed matrix emulsion; according to the mass ratio of 1:10, stir and mix reactive red 195 and titanate coupling agent 201, and ultrasonically disperse at 200W for 10 minutes to obtain a dye modification solution. Weigh 10 parts of dye modification solution, 45 parts of water glass with a modulus of 1.5, 35 parts of 15% hydrochloric acid by mass fraction and 65 parts of dispersed matrix emulsion in a beaker, heat and stir in a water bath at 25°C, and keep warm for 2 hours. , to obtain a mixed solution, according to the mass ratio of 1:8, acetone was added dropwise to the mixed solution, and the acetone addition time was controlled to be 10 minutes. Rinse with water three times, then dry at 400°...

example 2

[0020] In terms of parts by weight, weigh 47 parts of n-butanol, 12 parts of cyclohexane, 4 parts of propylene glycol polyoxyethylene polyoxypropylene ether, and 57 parts of deionized water in a beaker, stir and mix them, and put them under 250W ultrasonic Disperse for 12 minutes to obtain a dispersed matrix emulsion; according to the mass ratio of 1:10, stir and mix reactive red 120 and titanate coupling agent TC-114, and ultrasonically disperse at 250W for 12 minutes to obtain a dye modification solution, calculated in parts by weight 12 parts of dye modification solution, 47 parts of water glass with a modulus of 1.7, 37 parts of hydrochloric acid with a mass fraction of 15% and 67 parts of dispersed matrix emulsion were weighed and placed in a beaker, heated in a water bath at 27°C and mixed with stirring, and kept for reaction After 2.5 hours, the mixed solution was obtained, and acetone was added dropwise to the mixed solution according to the mass ratio of 1:8, and the a...

example 3

[0022] In terms of parts by weight, weigh 50 parts of n-butanol, 15 parts of cyclohexane, 5 parts of propylene glycol polyoxyethylene polyoxypropylene ether, and 60 parts of deionized water in a beaker, stir and mix, and place under 00W for ultrasonic Disperse for 15 minutes to obtain a dispersed matrix emulsion; according to the mass ratio of 1:10, stir and mix reactive red 111 and titanate coupling agent YB-403, and ultrasonically disperse at 300W for 15 minutes to obtain a dye modification solution, calculated in parts by weight 15 parts of dye modification solution, 50 parts of water glass with a modulus of 2.0, 40 parts of 15% hydrochloric acid by mass fraction and 70 parts of dispersed matrix emulsion were weighed in a beaker, heated in a water bath at 30°C and mixed with stirring, and kept for reaction After 3 hours, the mixed solution was obtained, and acetone was added dropwise to the mixed solution according to the mass ratio of 1:8, and the acetone dropping time was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com