Automatic control system of glass production flow

An automatic control system and production process technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of low glass quality and low efficiency of glass production process, achieve uniform feeding, convenient parameter setting, and reduce labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

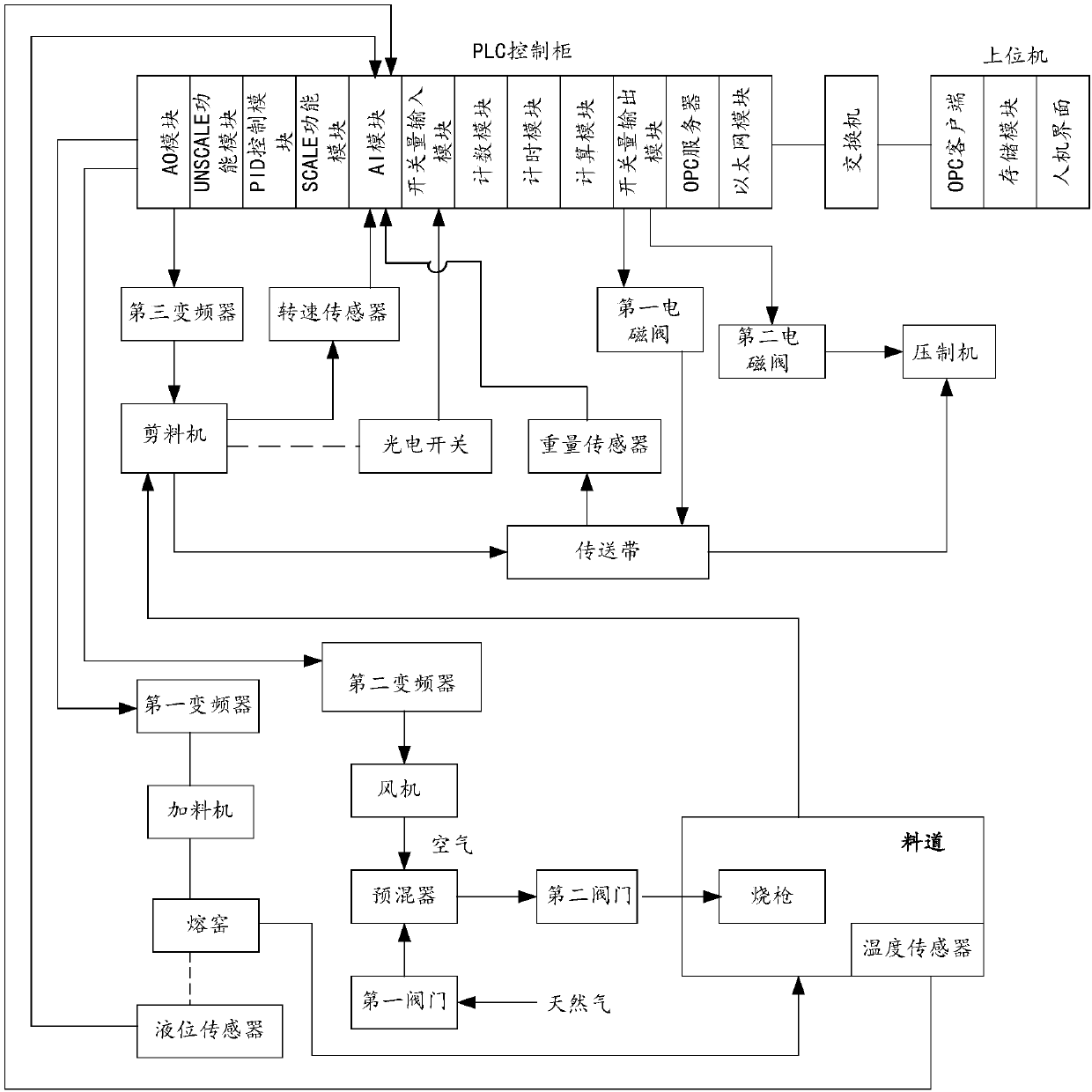

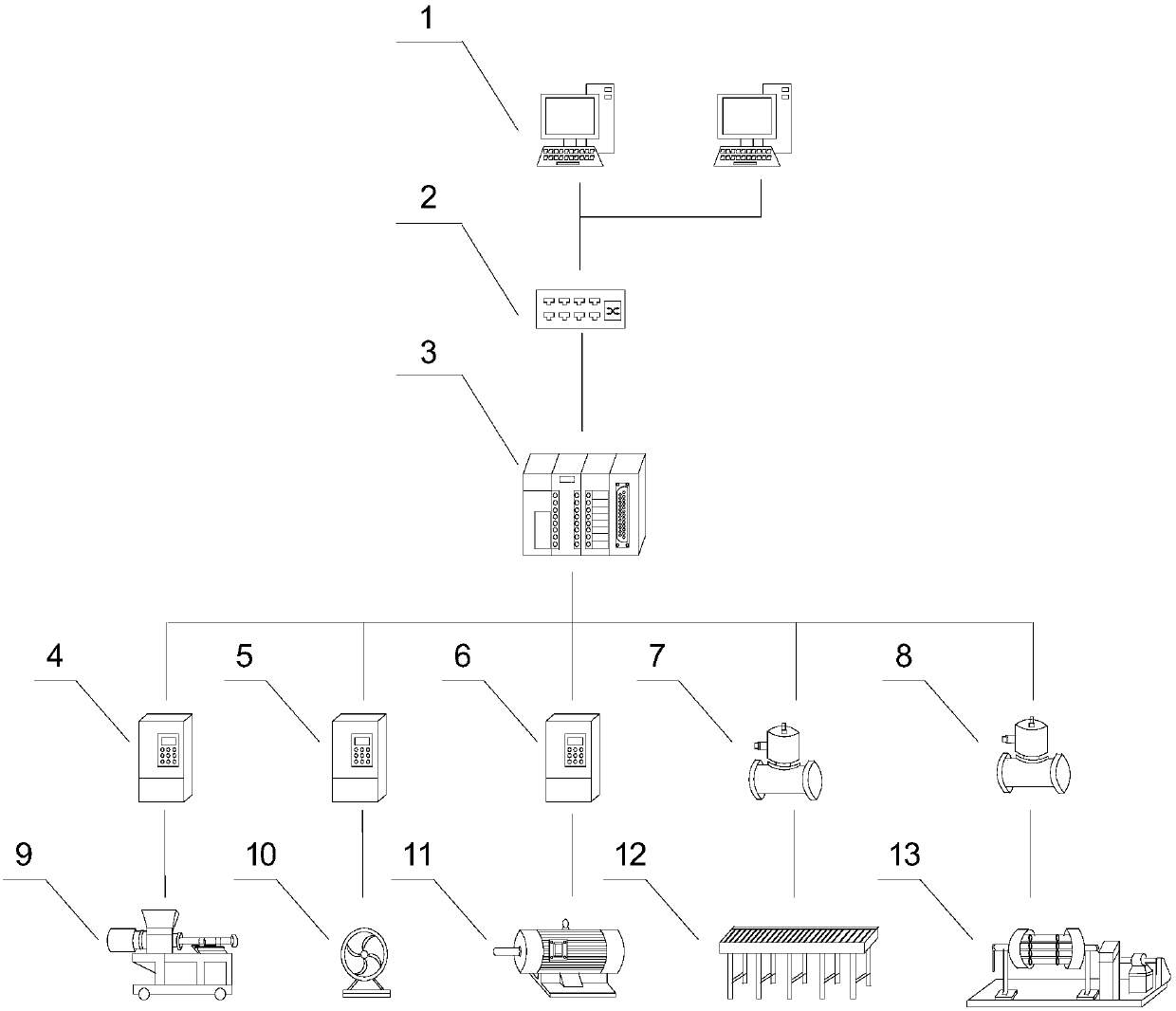

[0031] Combine below figure 1 and figure 2 The present invention will be described in detail.

[0032] An automatic control system for a glass production process, the system includes a PLC control cabinet 3, a first frequency converter 4 for controlling the liquid level of a melting furnace, a feeder 5 connected to the first frequency converter, and a feeder 5 connected The melting furnace and the liquid level sensor located around the melting furnace, the second frequency converter 6 used to realize the temperature control of the forehearth, the fan 7 connected with the second frequency converter 6, the premixer connected with the fan 7, and the premixer The first valve and the second valve connected to the device, the burning gun connected to the second valve, the temperature sensor conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com