Dislocation-resistant hip joint prosthesis of 3D printing femoral head and manufacturing method thereof

A hip joint prosthesis and printing stock technology, applied in the medical field, can solve the problems of hip joint dislocation, damage to the locking mechanism, limited over-radius range of the acetabular lining, etc., and achieve the effect of increasing restraint and preventing dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

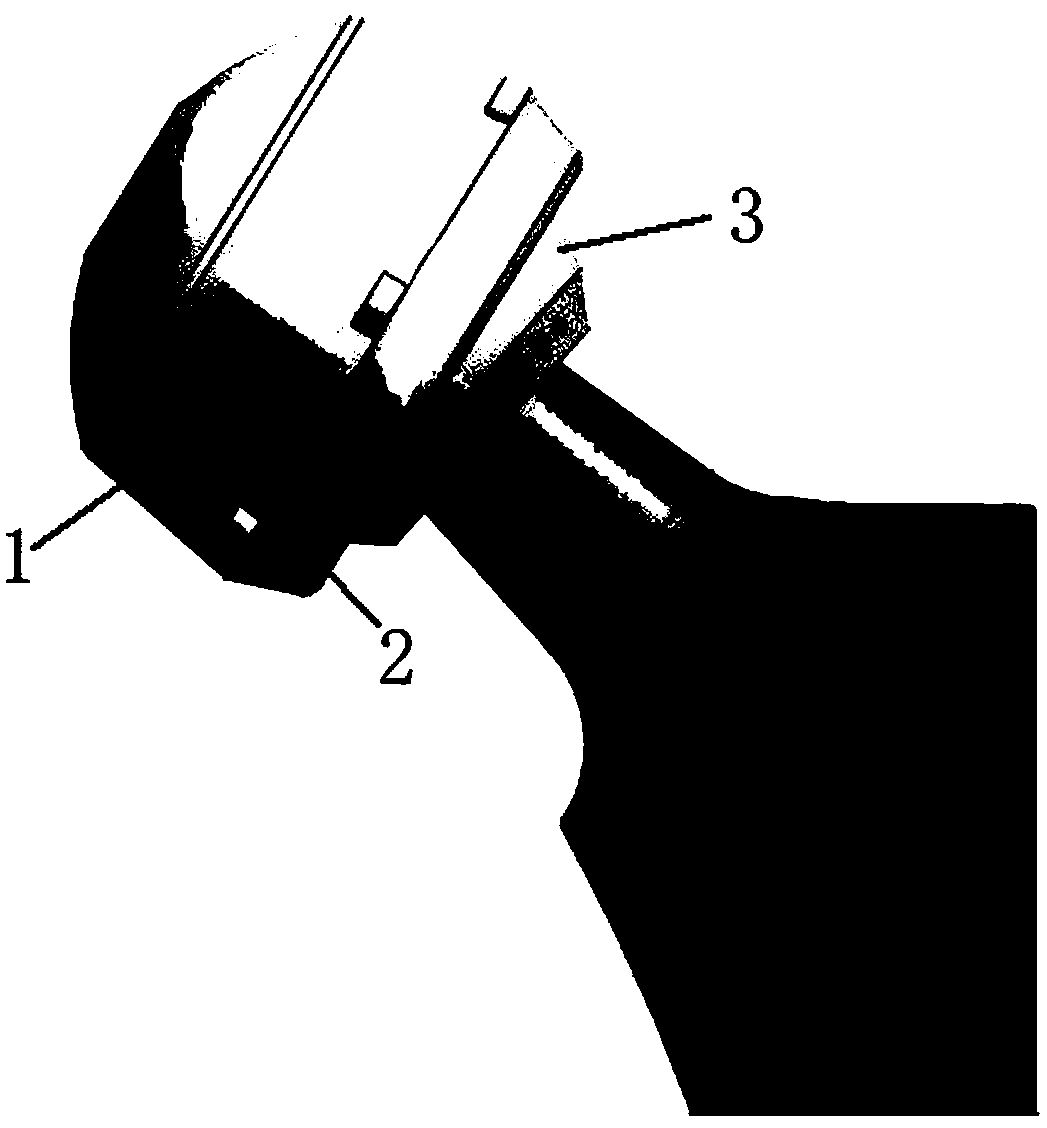

[0029] like figure 1 and figure 2 The hip joint prosthesis shown includes the acetabular lining, the acetabular lining is provided with a hemispherical groove 1, the edge of the hemispherical groove 1 is integrally formed with a super-radius buckle edge 2, and the inside of the acetabular lining There is a 3D printed femoral head prosthesis 3, the 3D printed femoral head prosthesis 3 is spherical, the 3D printed femoral head prosthesis 3 is the same size as the internal space of the acetabular lining, and the diameter of the opening of the super-radius buckle is smaller than 3D Print the diameter of the femoral head prosthesis 3, and the 3D printed femoral head prosthesis 3 is provided with a femoral neck prosthesis (the square groove in the middle of the femoral head on the way of the section is the position where the femoral neck is installed). The acetabular lining is made of highly cross-linked polyethylene, and the femoral head prosthesis is 3D printed with metal materi...

Embodiment 2

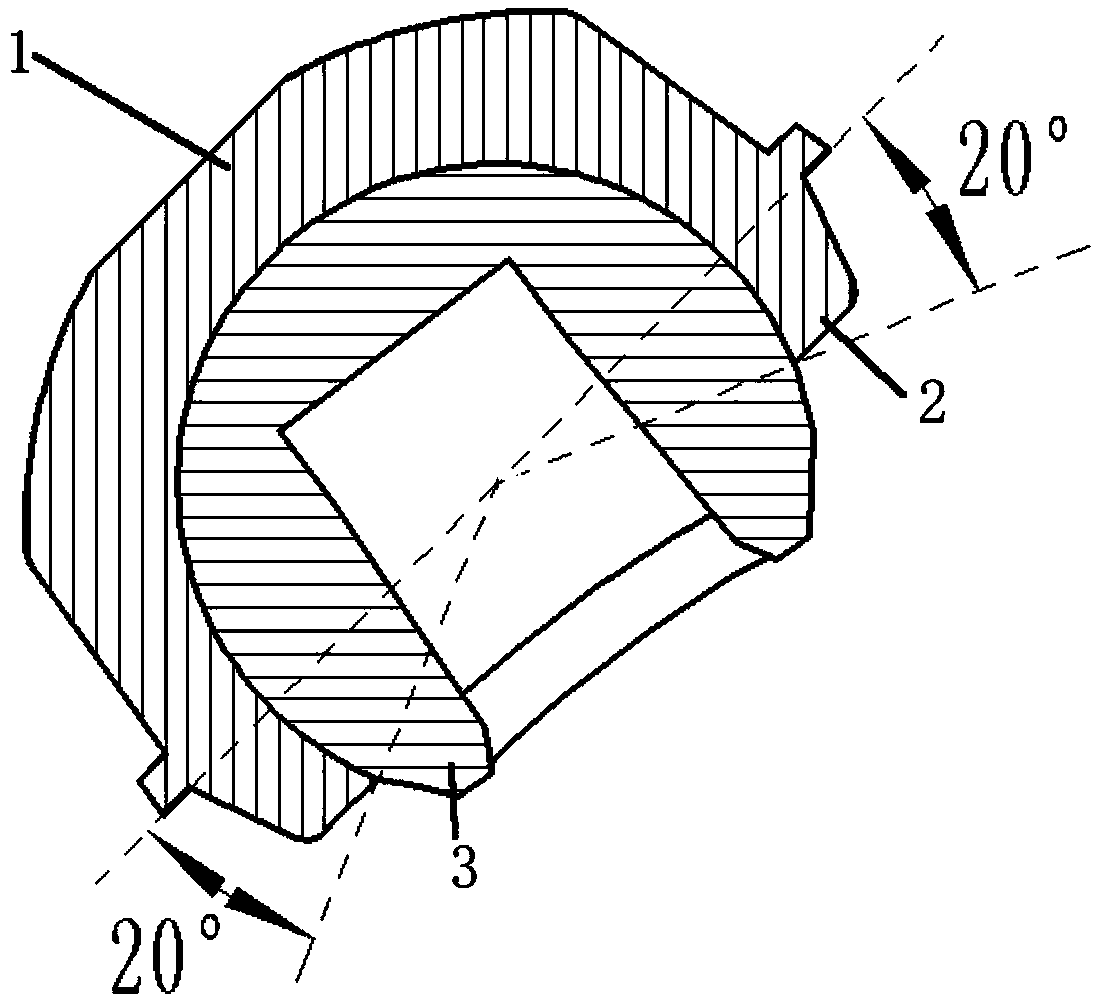

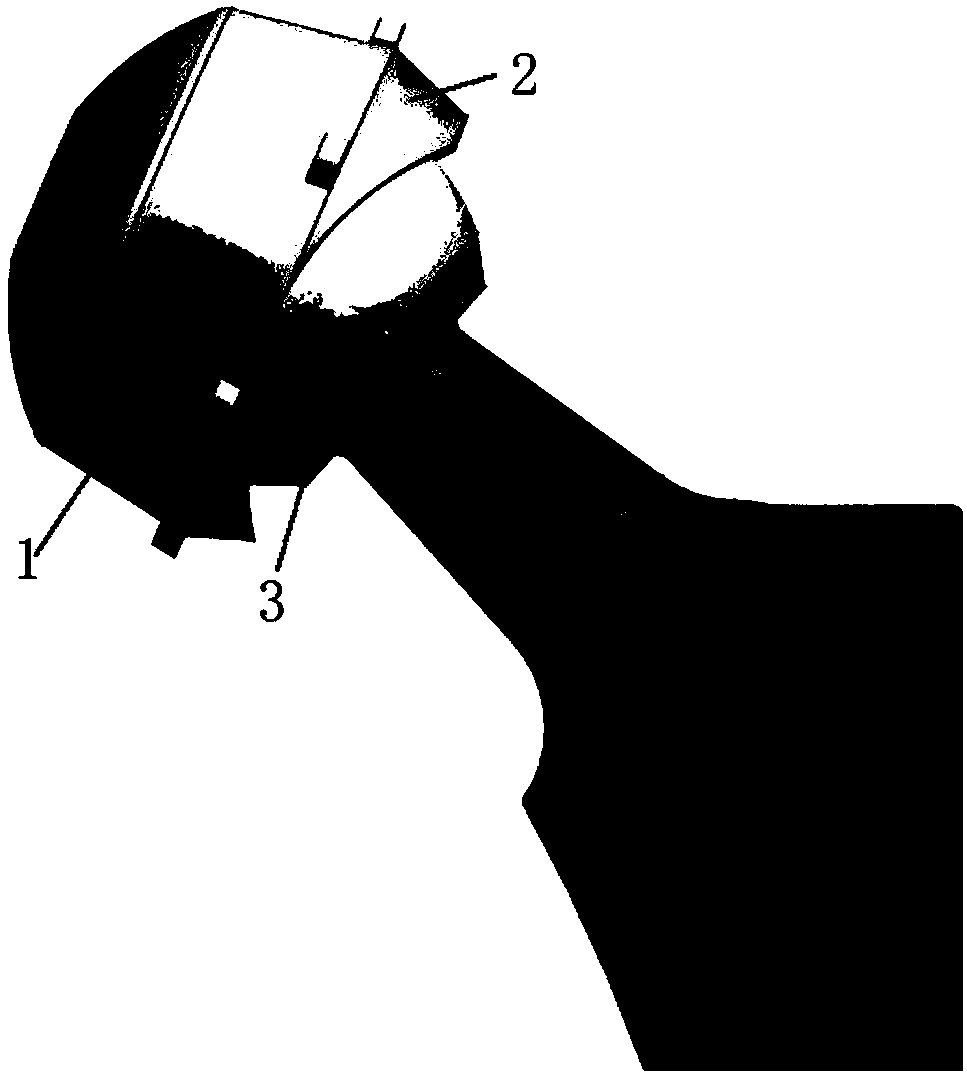

[0036] like image 3 and Figure 4 As shown, in this embodiment, the super-radius button edge on the acetabular lining is designed in a wavy shape, including two high points and two low points, and the distance between two adjacent points is a quarter of a circle and the distance between two adjacent points is wavy. There is a smooth curve connection between them; the super-radius buckle does not exceed the radius at the first low point and the second low point, and the super-radius buckle at the first high point has an arc of 10°-40°, and the super-radius buckle The super-radius arc at the second highest point is 5°-25°. And the sum of the super-radius radians at the first high point and the second high point should be less than 45°. It is equivalent to extending two wavy super-radius buckle edges integrally from the upper and lower parts of the hemispherical groove, and forming two left and right grooves at the intersection of the two waves ( image 3 The upper wave-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com