Galvanized steel sheet double-beam laser splicing and welding method and system

A technology of galvanized steel sheet and welding method, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of high processing cost, difficult to maintain consistent gap, low efficiency, etc., and achieve good welding effect , easy control, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

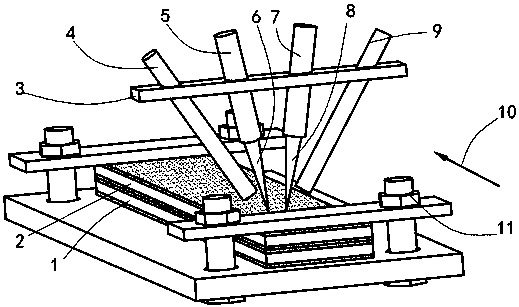

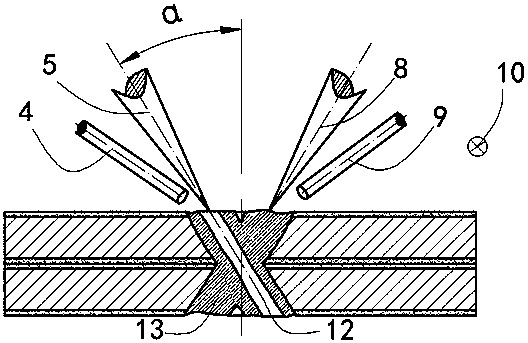

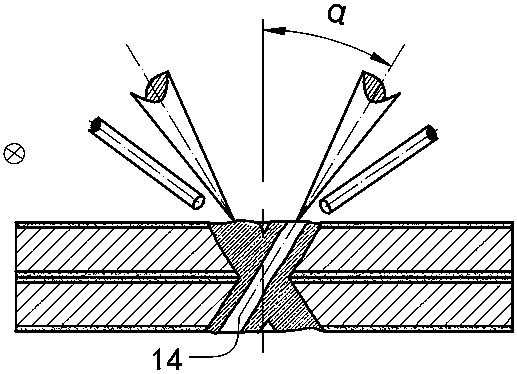

[0030] The following will be combined with Figure 1-5 The technical solution of the present invention will be described in detail along with specific embodiments.

[0031] Such as figure 1 As shown in -5, in the embodiment of the present invention, a method for double-beam laser lap welding of galvanized steel sheets includes the following steps.

[0032] Step 1. Provide the first workpiece 1 and the second workpiece 2 that require lap welding. The first workpiece 1 and the second workpiece 2 are both galvanized steel sheets, which can be formed by mechanical processing. In this embodiment, the thickness of the first workpiece 1 and the second workpiece 2 is 0.5mm-3mm.

[0033] Step 2, remove the impurities on the upper and lower surfaces of the first workpiece 1 and the second workpiece 2, and use the welding fixture 11 to accurately stack and clamp the first workpiece 1 and the second workpiece 2 vertically up and down, so that the first workpiece 1 and the second workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com