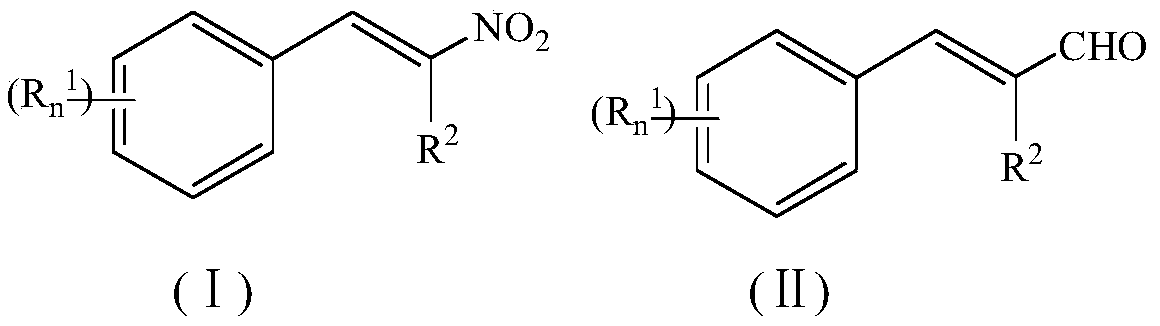

A kind of synthetic method of nitroalkene compound

A synthesis method and nitroolefin technology, applied in the field of synthesis of nitroolefin compounds, can solve the problems of difficult post-processing, low reaction yield, expensive raw materials, etc., and achieve strong substrate universality, few side reactions, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

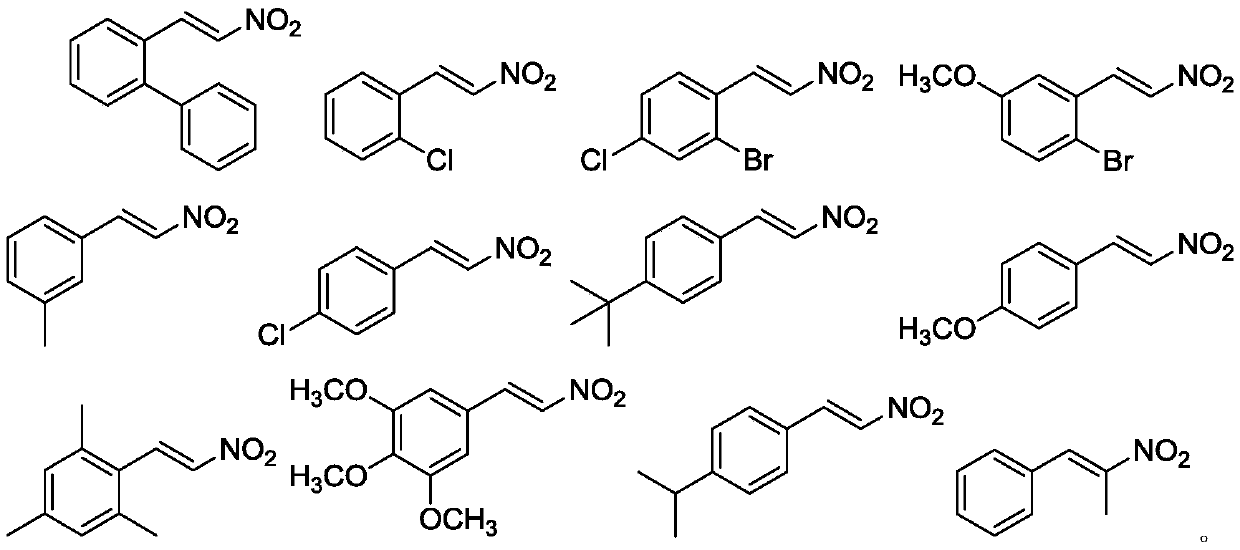

Method used

Image

Examples

Embodiment 1

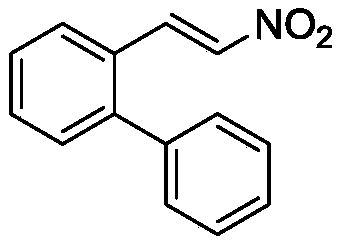

[0031]

[0032] Add 0.3mmol of o-phenylcinnamaldehyde and 0.45mmol of copper nitrate trihydrate into a 15mL pressure-resistant tube, and then add 3mL of a mixture of acetonitrile and water (V (acetonitrile): V (water) = 100:1) as a solvent. Then, magnetic stirring was performed at 130° C. for 12 h. Then, two spoons of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the solvent was removed by distillation under reduced pressure, and the residue was separated by column chromatography, and V (petroleum ether): V (ethyl acetate ) = 20:1 mixed solution was used as eluent to elute, the eluate containing the target product was collected, and the solvent was evaporated to obtain a pure product, the amount of which was 0.174 mmol. The material was a yellow solid with the chemical name 2-nitro-ortho-styrene, and the yield was 58%.

[0033] Characterization data: 1 H NMR (CDCl 3 ,500MHz):8.08(d,J=13.5Hz,1H),7.68(d,J=8.0Hz,1H),7.58-7.44(m,7H)...

Embodiment 2

[0035]

[0036] Add 0.3mmol of o-phenylcinnamaldehyde and 0.3mmol of silver nitrate into a 15mL pressure-resistant tube, and then add 3mL of acetonitrile and water mixture (V (acetonitrile): V (water) = 50:1) as a solvent. Then, magnetic stirring was performed at 150° C. for 24 h. Then, two spoons of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the solvent was removed by distillation under reduced pressure, and the residue was separated by column chromatography, and V (petroleum ether): V (ethyl acetate ) = 20:1 mixed solution was used as eluent to elute, the eluate containing the target product was collected, and the solvent was evaporated to obtain the pure product, the amount of the pure product was 0.162 mmol. The material was a yellow solid with the chemical name 2-nitro-o-styrene, yield 54%.

[0037] Characterization data: 1 H NMR (CDCl 3 ,500MHz):8.08(d,J=13.5Hz,1H),7.68(d,J=8.0Hz,1H),7.58-7.44(m,7H),7.34-7.32(m,2H); 13...

Embodiment 3

[0039]

[0040] Add 0.3 mmol of o-phenylcinnamaldehyde and 0.9 mmol of ferric nitrate nonahydrate into a 15 mL pressure-resistant tube, and then add 3 mL of acetonitrile and water mixture (V (acetonitrile): V (water) = 500: 1) as a solvent. Then, magnetically stirred at 100° C. for 8 h. Then, two tablespoons of column chromatography silica gel (100-200 mesh) were added to the reaction solution, and the solvent was removed by distillation under reduced pressure, and the residue was separated by column chromatography, and V (petroleum ether): V (ethyl acetate )=20:1 mixed solution was used as the eluent to elute, the eluate containing the target product was collected, and the solvent was evaporated to obtain the pure product, the amount of the pure product was 0.111 mmol. The material was a yellow solid with the chemical name 2-nitro-o-styrene, yield 37%.

[0041] Characterization data: 1 H NMR (CDCl 3 ,500MHz):8.08(d,J=13.5Hz,1H),7.68(d,J=8.0Hz,1H),7.58-7.44(m,7H),7.34-7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com