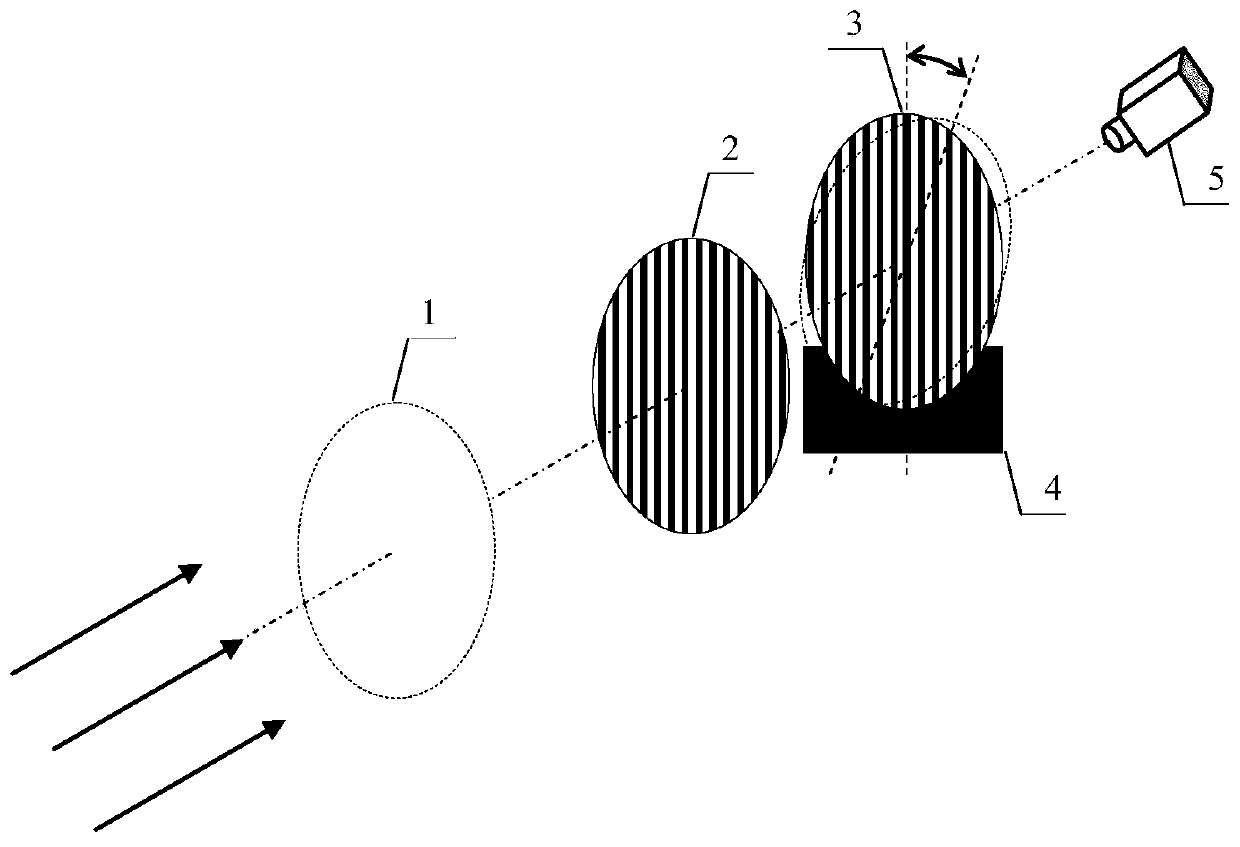

A Calibration Method of Double Grating Focal Length Measuring Instrument

A calibration method and double grating technology, applied in the direction of testing optical performance, etc., can solve the problems of limited accuracy, limited medium and long focal length measurement systems, lack of high-precision measurement methods for accurate measurement, etc., to improve calibration accuracy and reduce complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

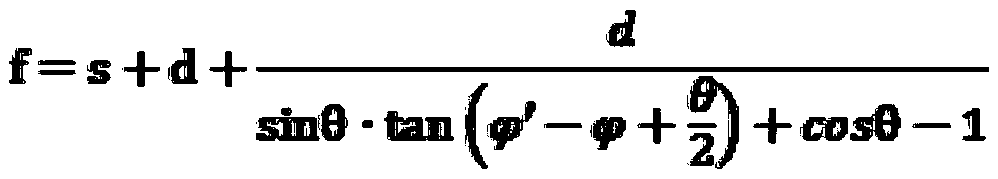

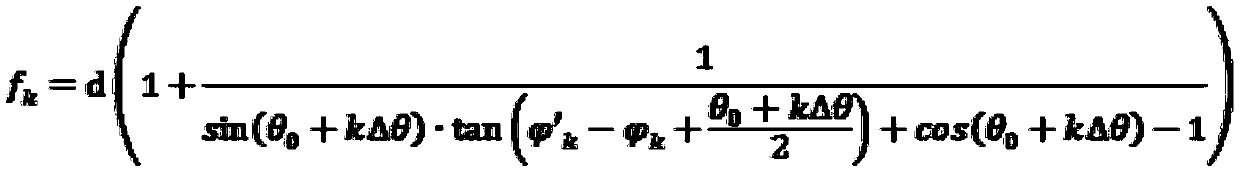

[0043] In this embodiment, calibration lenses with focal length design values of 5m and 59m are used. By adjusting the high-precision precision angular displacement stage, the step length of the included angle of the grating line is adjusted with equal precision in each step, k=20, and the included angle of the grating line is changed to obtain the corresponding The interference fringes are collected by the imaging acquisition system and solved by Fourier transform through the interference fringe angle calculation software package. After each adjustment, return the precision angular displacement stage to zero before performing the next adjustment to ensure repeatable positioning accuracy. Bring all the data into the equation system, apply the focal length non-correlated least squares calibration method for combined calibration, and accurately solve the zero error Δθ of the double grating interferometer 0 Adjust the step size Δθ with the grid line angle.

[0044] Calibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com