An automatic test method for the drag speed of electronic countermeasure equipment

An electronic countermeasures and automatic test technology, applied in the field of testing, can solve the problems of low test efficiency, large random error of drag speed, deviation from the true value, etc., to reduce the uncertainty of operation and observation, reduce the requirements of work skills, The effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

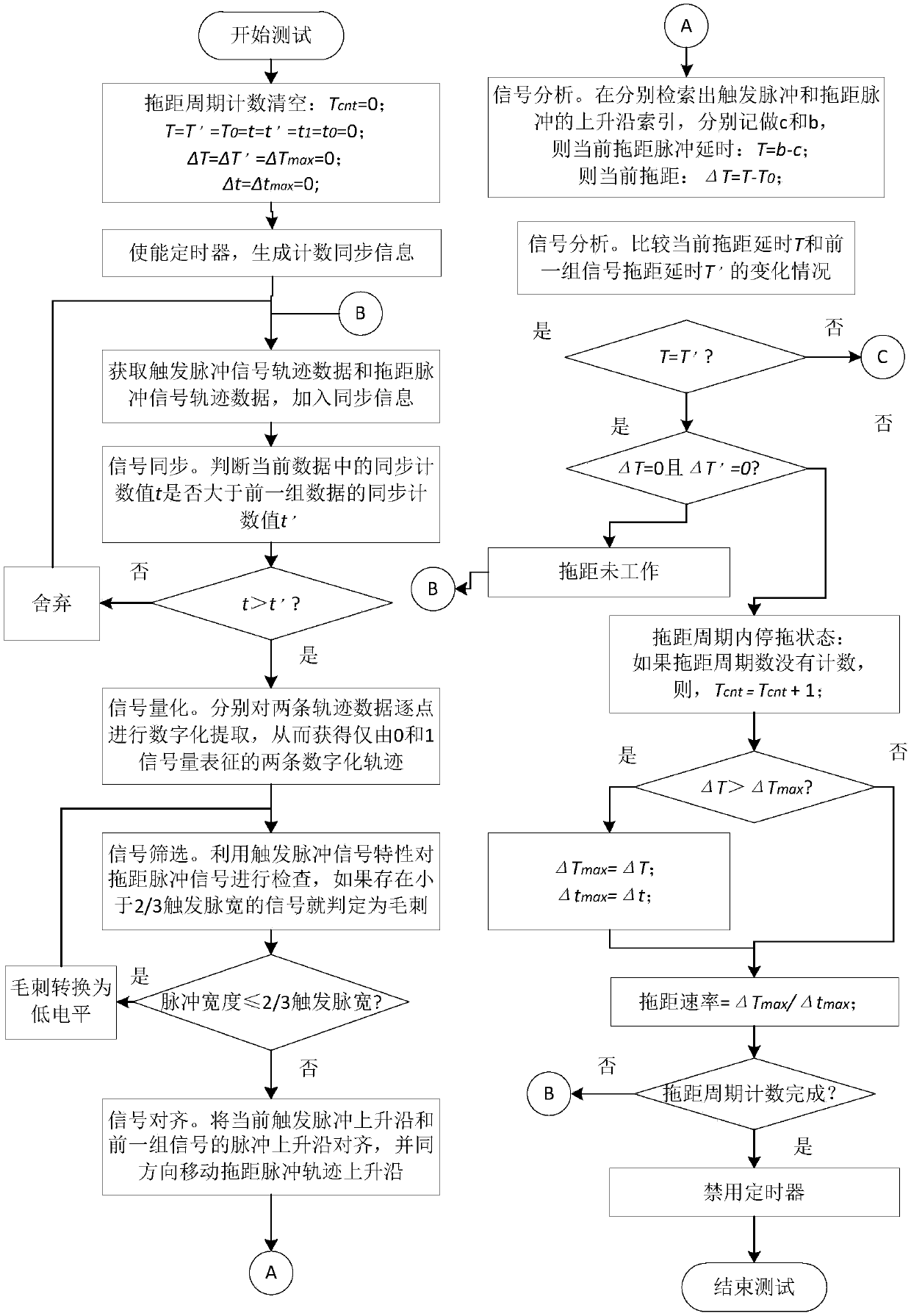

[0071] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

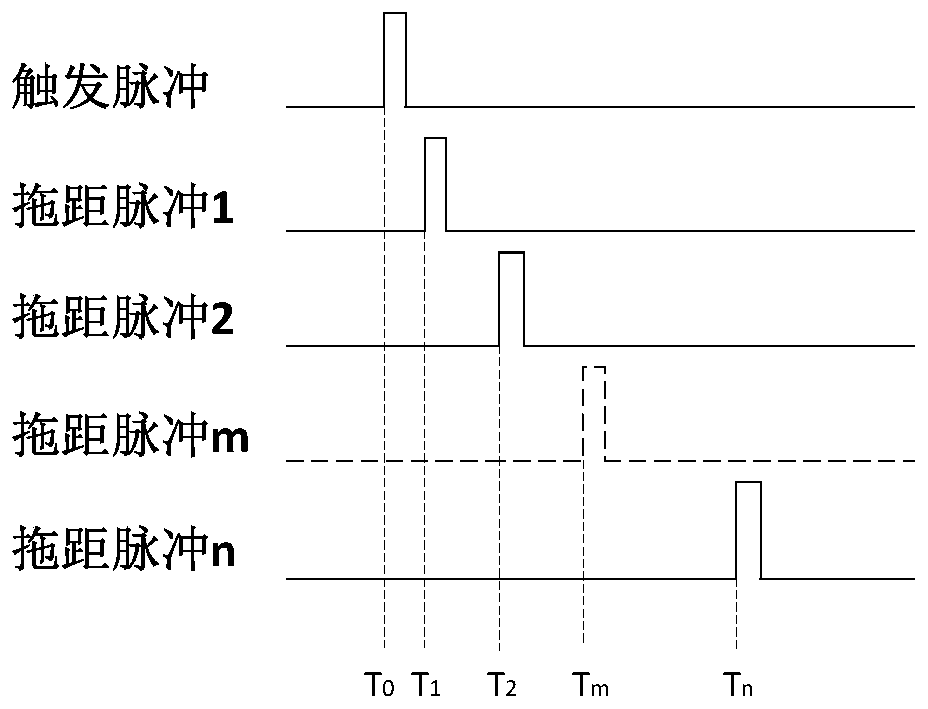

[0072] The present invention is an automatic test method for the tow rate of electronic countermeasure equipment, which can not only automatically test the tow rate parameters, but also use software to complete the drawing of the complete tow motion trajectory (referred to as "software tow afterglow" in the present invention) . It can be seen from formula (2) that the characterization of the trail speed needs to test two key parameters: trail distance ΔT and trail time Δt. Therefore, in order to accurately calculate the drag rate, the values of these two parameters must be accurately obtained by means of automatic testing.

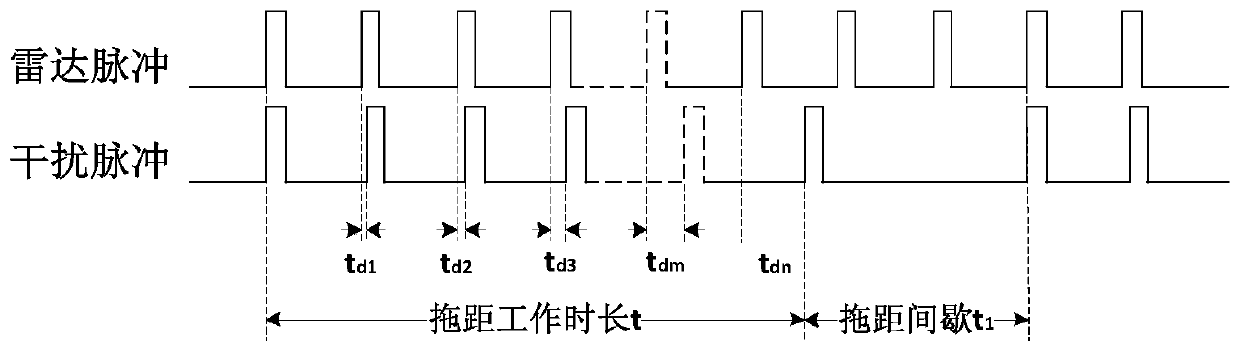

[0073] From figure 2 It can be seen that when the electronic countermeasure equipment is in the working state, ΔT is in a unidirectional positive growth state within a drag period. When the value of ΔT remains unchanged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com