Industrial robot for intelligent welding

An industrial robot, intelligent technology, applied in the field of intelligent robots, can solve the problems of inaccurate control, easy to produce errors, hurt people, etc., to achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

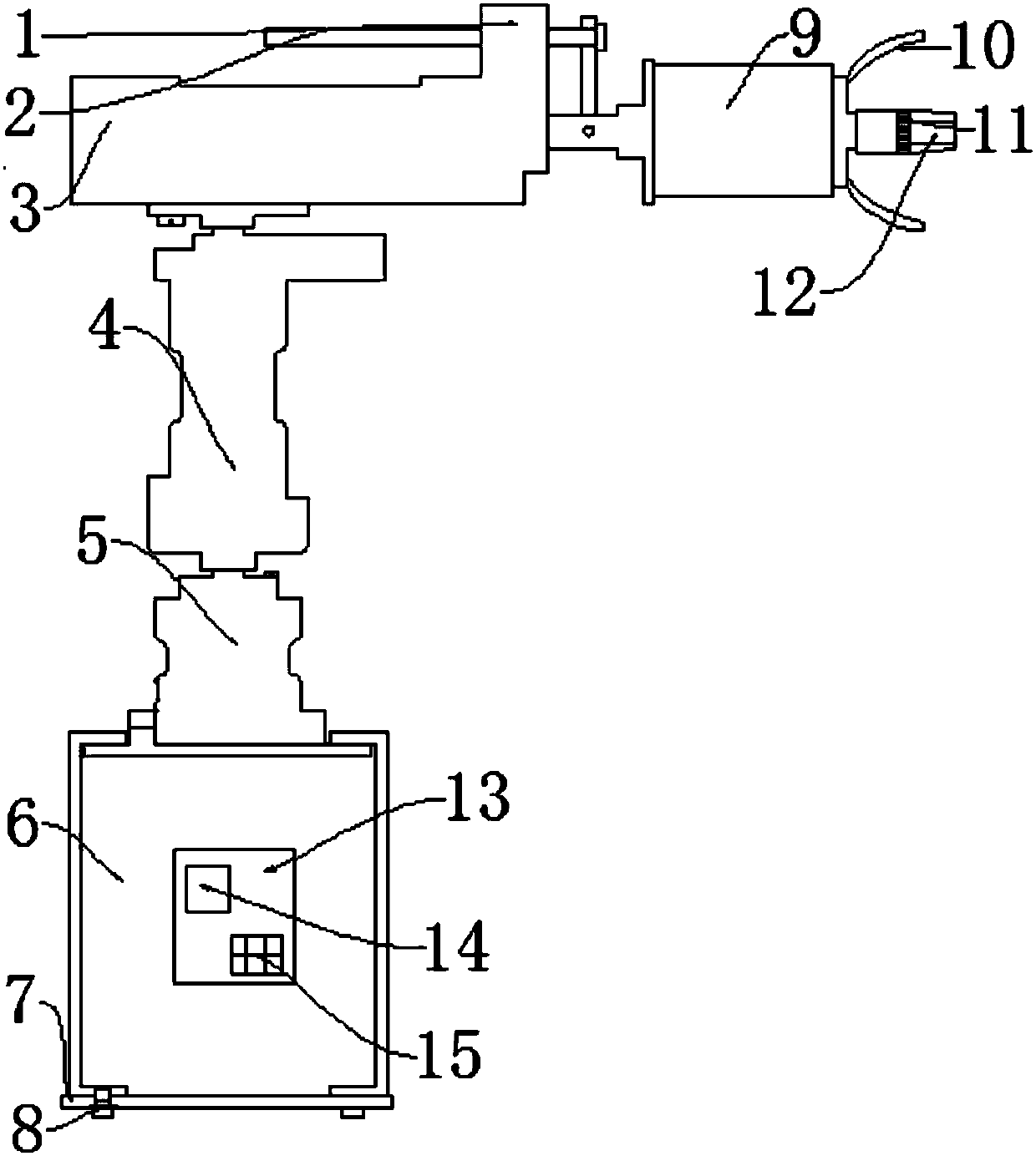

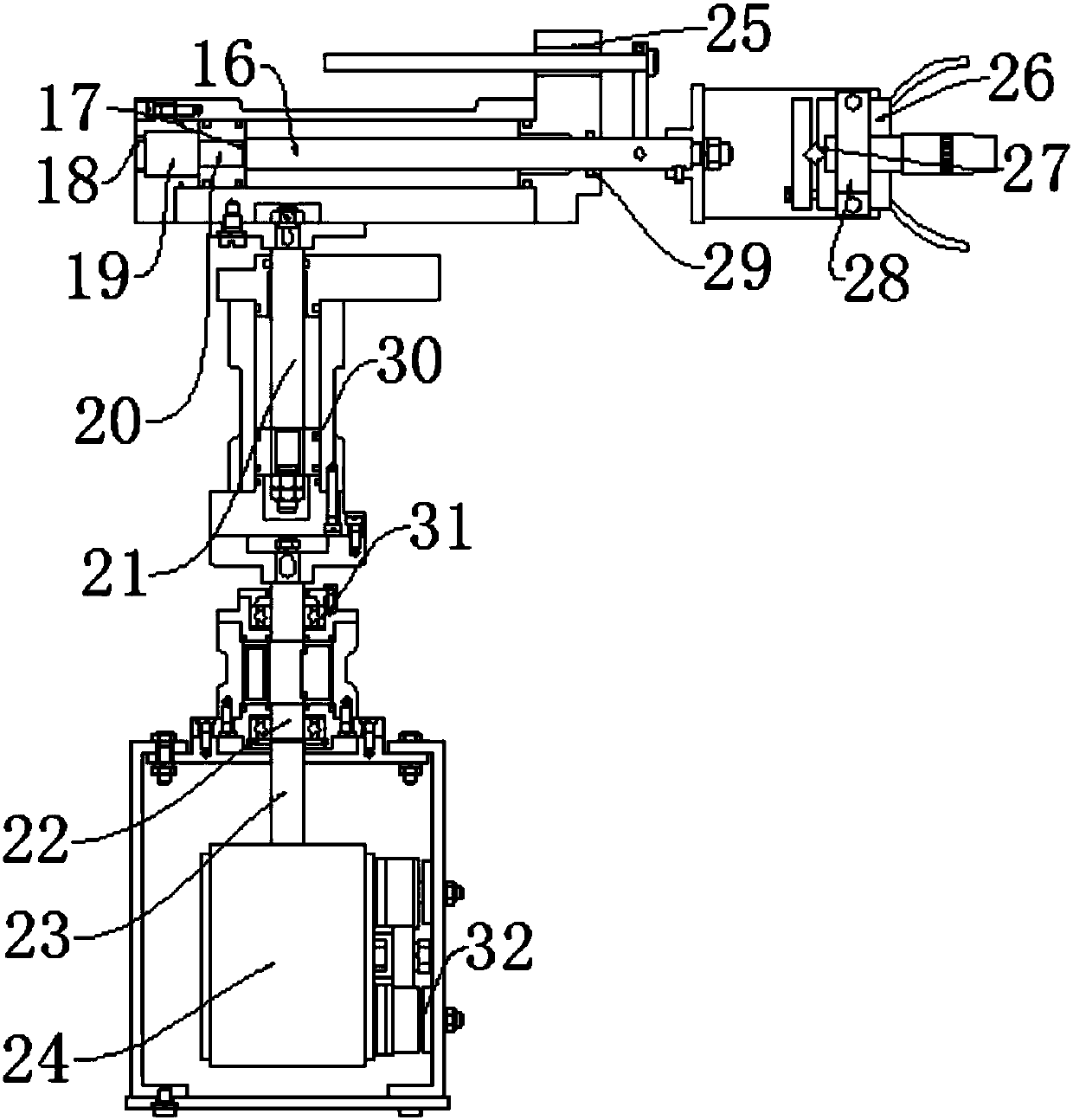

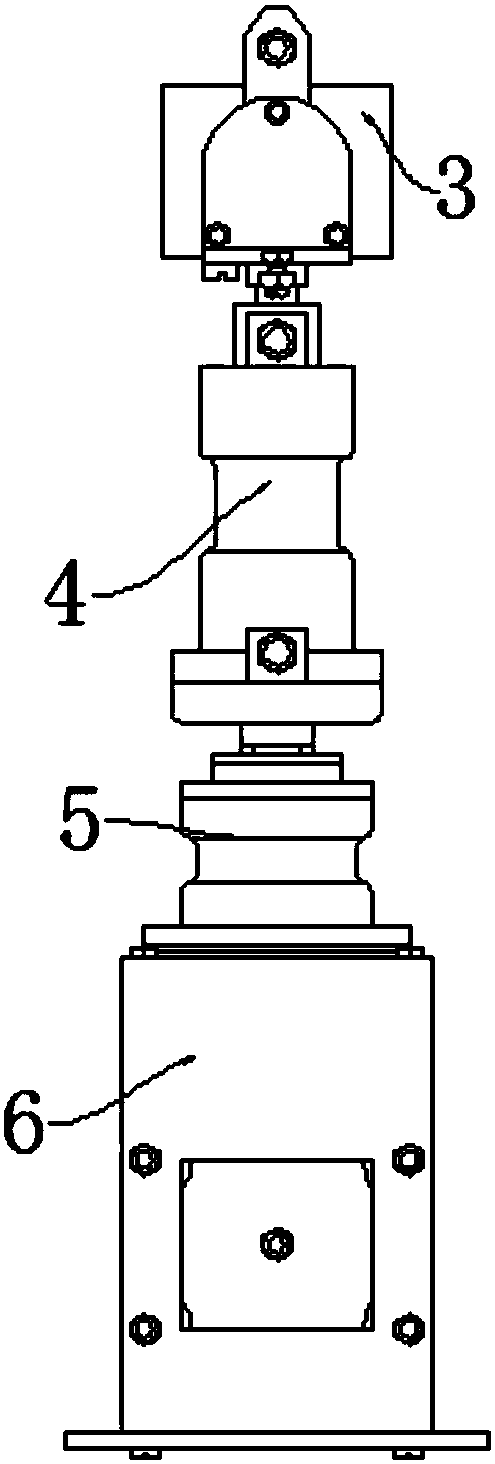

[0026] Such as Figure 1-Figure 3 As shown, an intelligent welding industrial robot includes a body 6, a base plate 7, a support pad 8 and a support 5, the bottom surface of the body 6 is provided with the base plate 7, and the bottom surface of the base plate 7 is provided with the support pad 8, The body 6 is provided with the support 5 above, the support arm 4 is provided above the support arm 4, the upper end of the support arm 4 is provided with a drive box 3, and the middle part of the drive box 3 is provided with a mounting bracket 1. A sleeve 25 is arranged inside the installation frame 1, a guide post 2 is arranged inside the sleeve 25, a heating chamber 9 is arranged at the end of the drive box 3, and a protective cover is arranged at the end of the heating chamber 9 10. The inner side of the body 6 is provided with a motor base 32, the motor base 32 is provided with a servo motor 24, the end of the servo motor 24 is provided with a motor shaft 23, and the end of the...

Embodiment 2

[0042] The general content of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, the material of the protective cover 10 in this embodiment is glass fiber, and the protective cover 10 is fixed on the On the welding head 12, the material in this way is easy to obtain, the production cost is low, and it is convenient for production and processing. At the same time, the processing method of the card slot is adopted to facilitate the timely replacement of the protective cover 10, and avoid affecting the protective cover 10 when it is damaged. Welding work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com