Plasma processing device and gas supply method

A gas supply and processing device technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, discharge tubes, etc., can solve the problems of inseparability, slow response, and differences, and achieve accurate control results, fast response speed, and selectivity less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

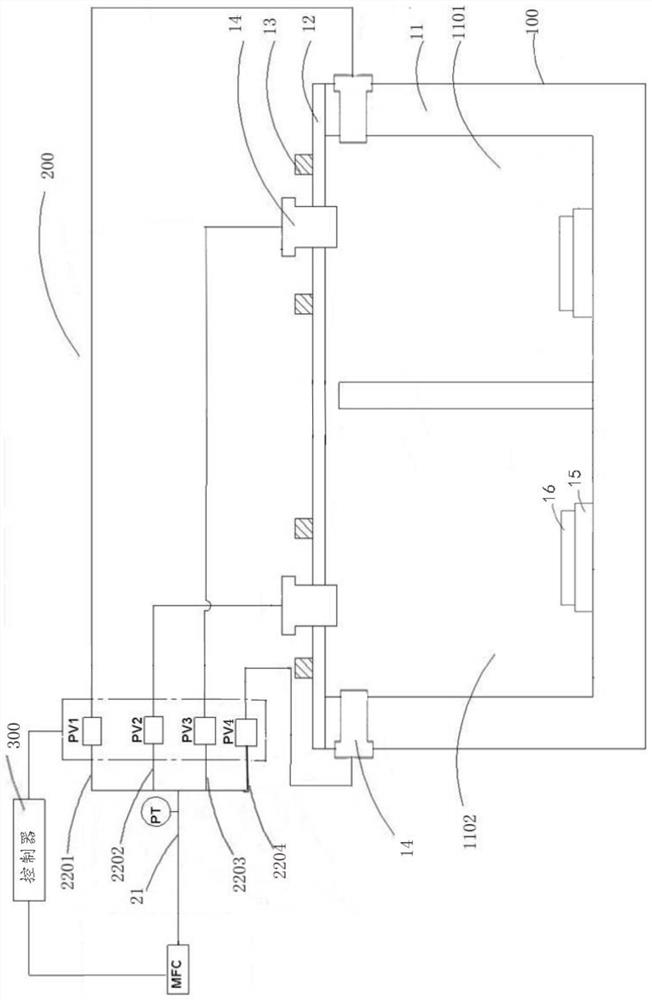

[0047] Such as figure 1 As shown, the four gas split delivery pipelines in the first embodiment are respectively the first gas split delivery pipeline 2201, the second gas split delivery pipeline 2202, the third gas split delivery pipeline 2203 and the fourth gas split delivery pipeline. Gas distribution pipeline 2204 , the reaction machine includes two reaction chambers arranged side by side, the first reaction chamber 1101 and the second reaction chamber 1102 . The first gas split delivery pipeline 2201 and the third gas split delivery pipeline 2203 deliver the reaction gas to the first reaction chamber 1101, and the second gas split delivery pipeline 2202 and the fourth gas split delivery pipeline 2204 deliver the reaction gas to the first reaction chamber 1101. The second reaction chamber 1102 delivers reaction gas.

[0048] The multi-channel gas split delivery pipeline of the present invention uses a flow control valve group. The above example is a one-way gas split deli...

Embodiment 2

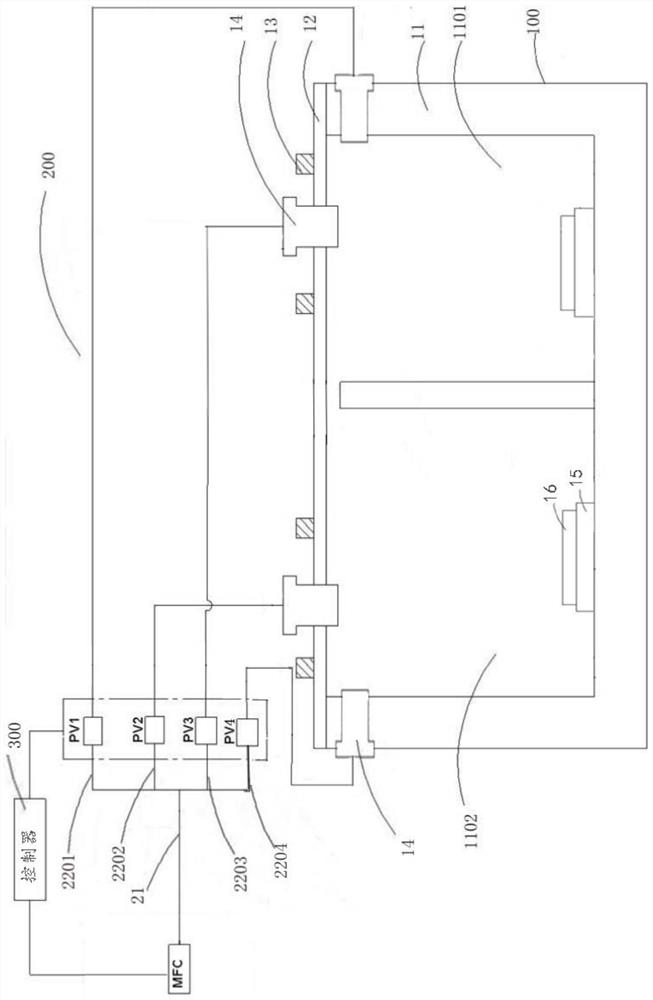

[0081] Such as figure 2 As shown, the four gas split delivery pipelines in the second embodiment are respectively the first gas split delivery pipeline 2201, the second gas split delivery pipeline 2202, the third gas split delivery pipeline 2203 and the fourth gas split delivery pipeline. Gas distribution pipeline 2204 , the reaction machine includes two reaction chambers arranged side by side, the first reaction chamber 1101 and the second reaction chamber 1102 . The first gas split delivery pipeline 2201 and the third gas split delivery pipeline 2203 deliver the reaction gas to the first reaction chamber 1101, and the second gas split delivery pipeline 2202 and the fourth gas split delivery pipeline 2204 deliver the reaction gas to the first reaction chamber 1101. The second reaction chamber 1102 delivers reaction gas.

[0082] The multi-channel gas split delivery pipeline of the present invention uses a flow control valve group. The above example is a one-way gas split de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com