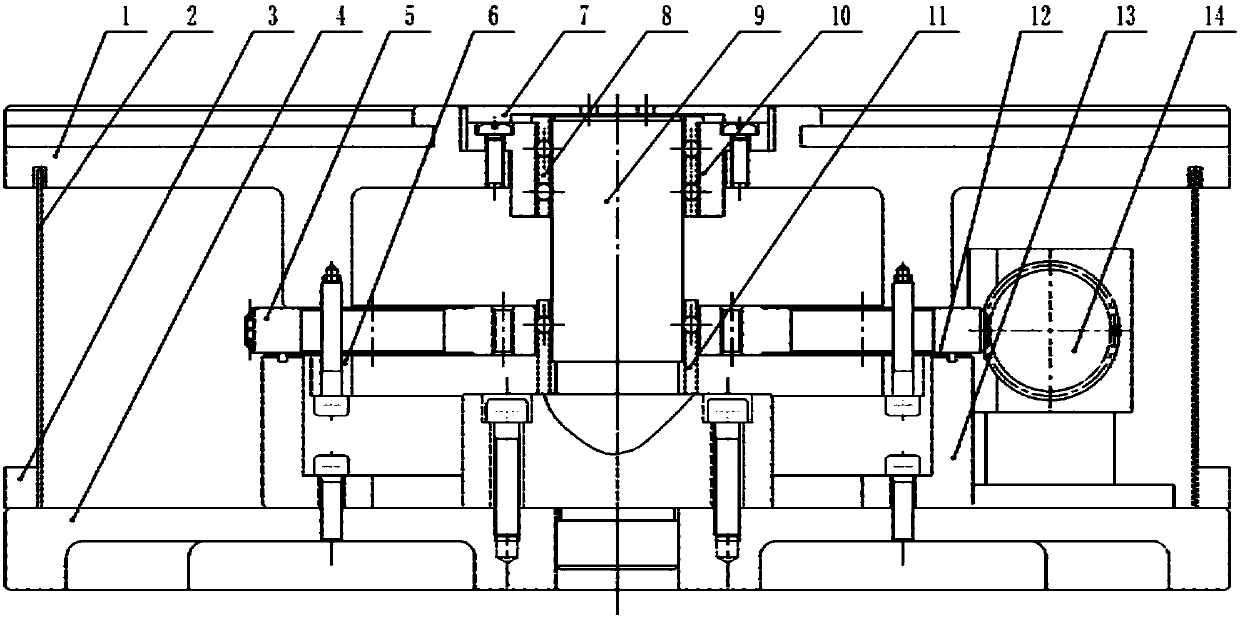

A precision indexing turntable and assembly method based on high-precision helical standard gear and worm drive

A standard gear and indexing turntable technology, applied in gear transmission, transmission, precision positioning equipment, etc., can solve the problem of low cost performance of indexing devices, and achieve good market application prospects, stable indexing accuracy, and high structural rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

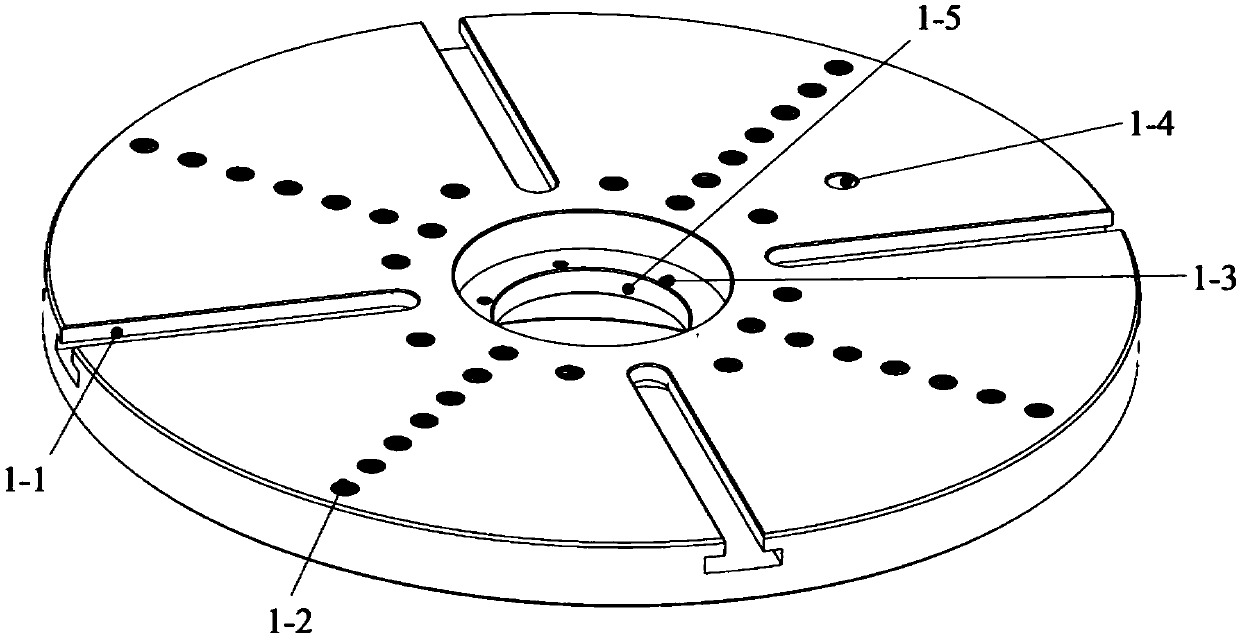

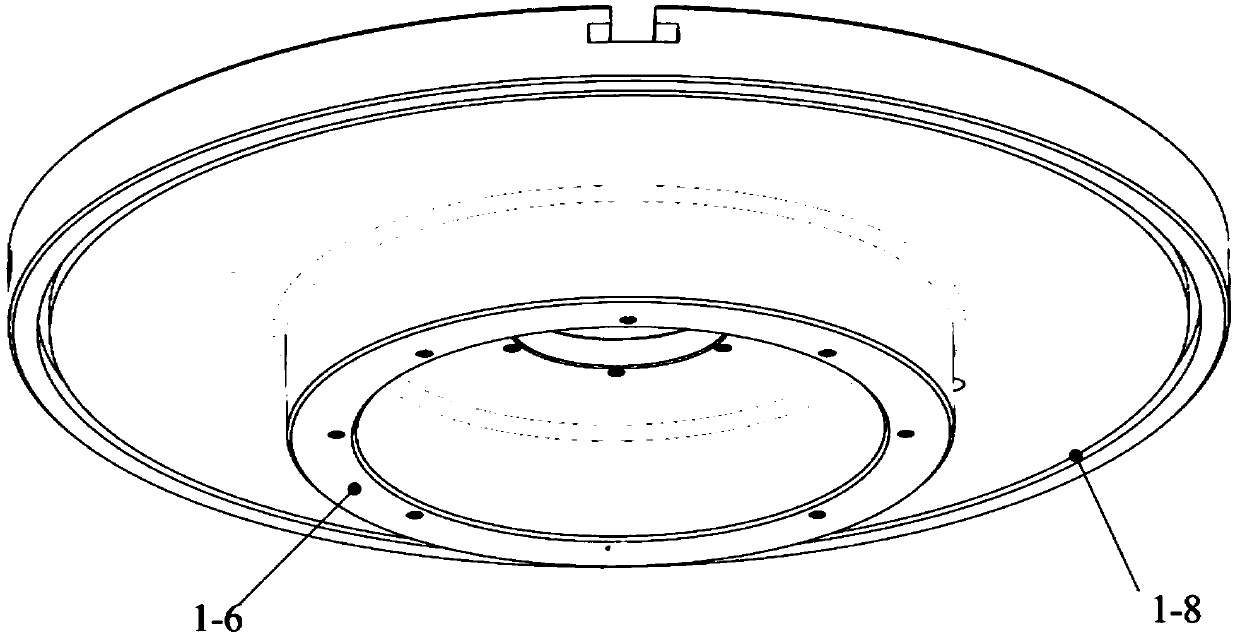

[0042] (1) Measures to improve the accuracy of the rotary shaft system

[0043] The precision of the rotary shaft system is very important to the indexing accuracy of the indexing table. Measures to ensure that the radial error of the indexing table does not exceed 0.5 μm from the processing accuracy and assembly accuracy of key parts and the selection accuracy of the spherical rolling elements used in the dense ball bushing include:

[0044] (1) Improve the machining accuracy of the mandrel 9 . Including the positioning accuracy of the mandrel 9 and the machining accuracy of the radial reference axis section of the indexing table. The shaft section, especially the part that is in contact with the spherical rolling elements in the dense ball bearing sleeves A and B, has a roundness error of less than 0.5 μm and a cylindricity error of less than 1 μm. Perpendicularity error is less than 2μm. At the same time, improve the flatness of the mandrel positioning reference plane an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com