Carbon molecular sieve strip extrusion device with rotating type perforated plate

A carbon molecular sieve and porous plate technology, applied in the field of forming devices, can solve the problems of inflexible production, complex structure, time-consuming, etc., and achieve the effects of reducing the phenomenon of bad bubbles, flexible production, and fewer bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

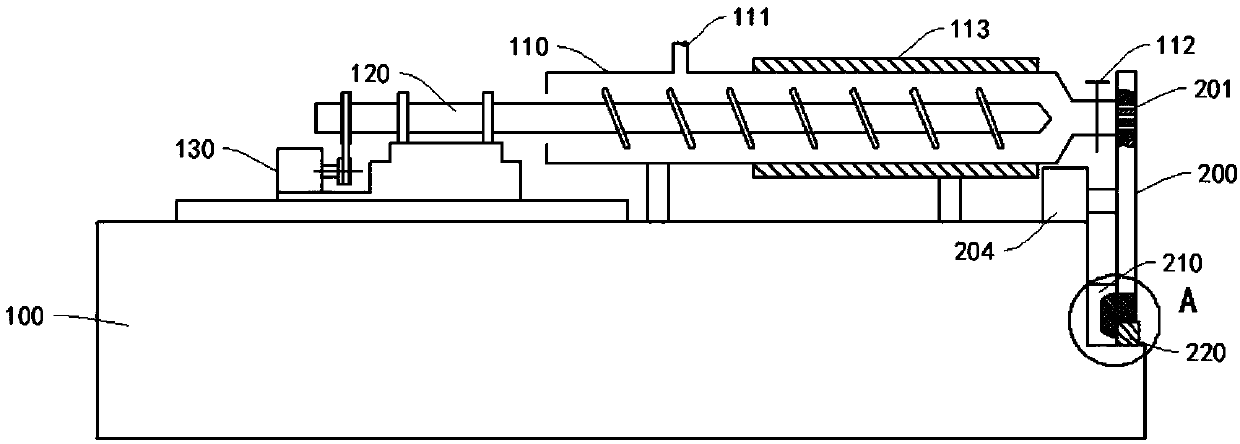

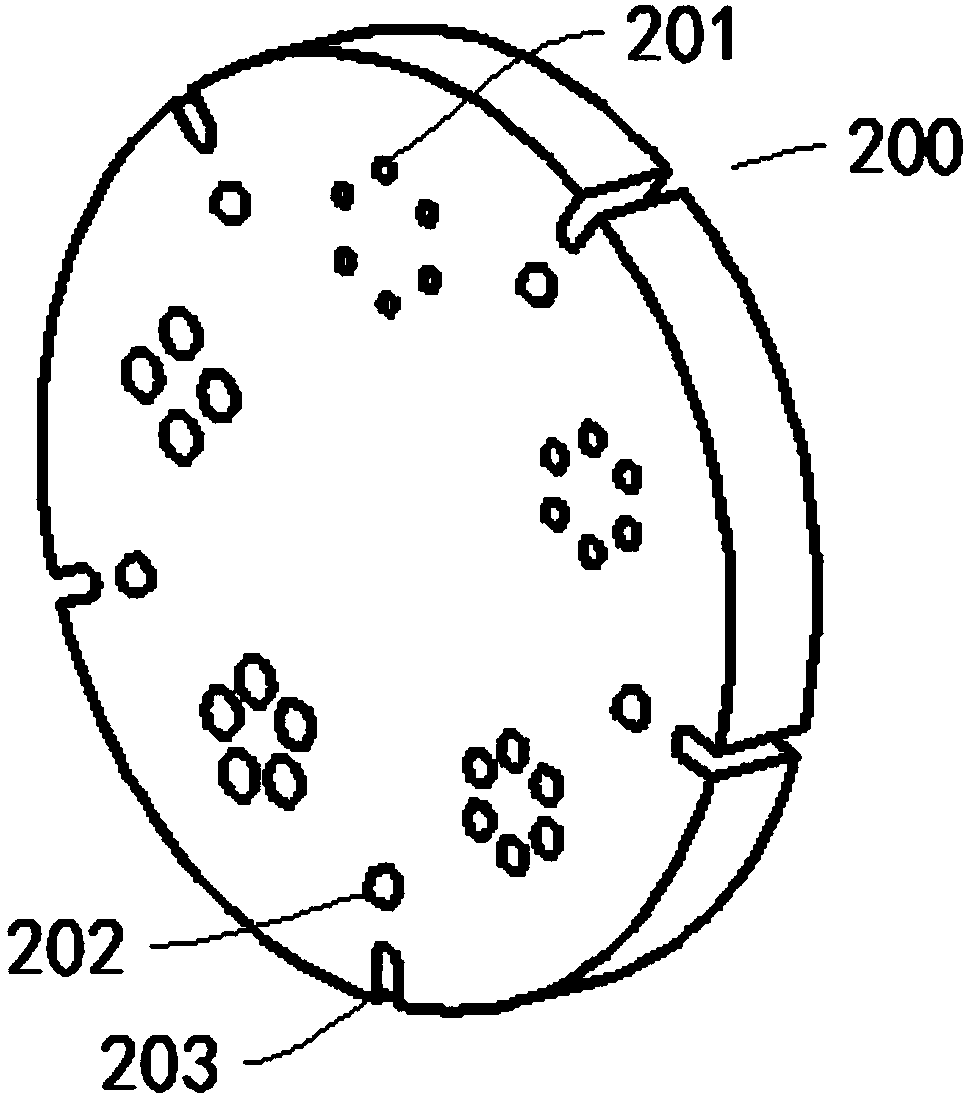

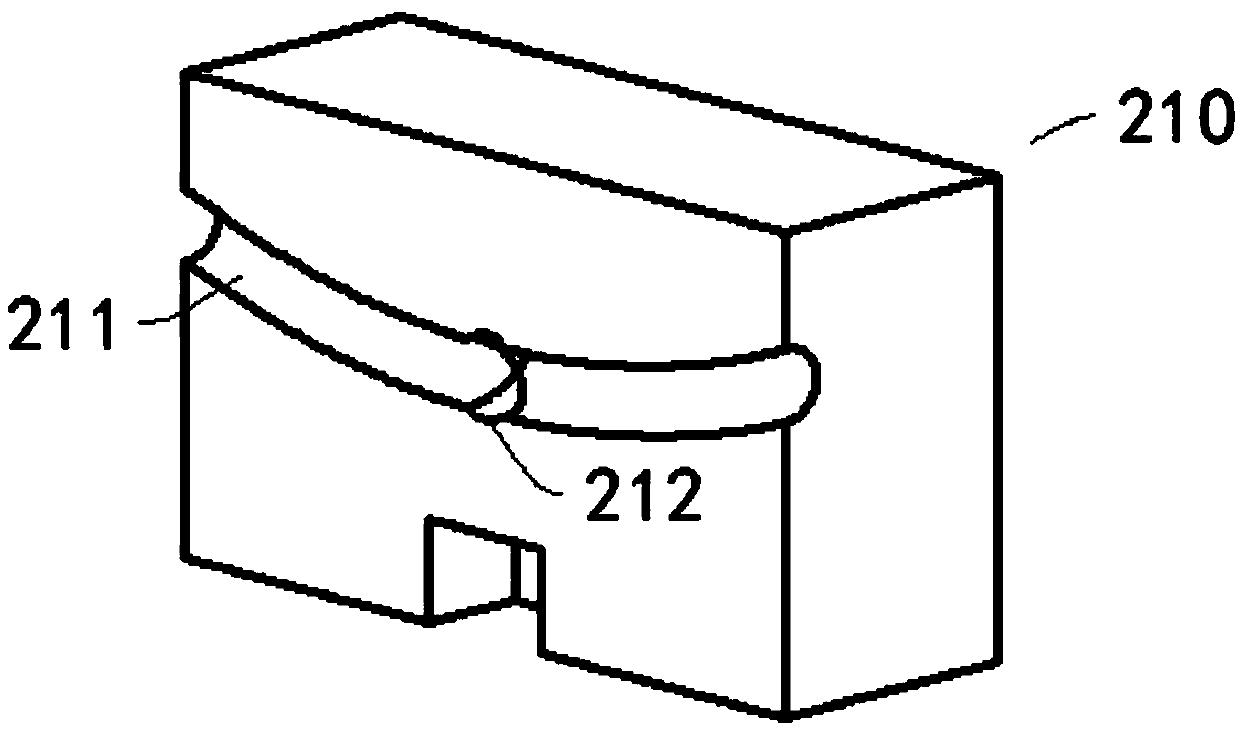

[0018] Example: A carbon molecular sieve extrusion device with a rotating porous plate, constituted as figure 1 As shown, it includes a base 100, an extrusion barrel 110 is provided on the base 100, a screw 120 is provided in the extrusion barrel 110, a feed pipe 111 is provided at the tail of the extrusion barrel 110, and a rotating head is provided at the head of the extrusion barrel 110. The rotary perforated plate 200 is provided with a valve 112 between the squeezing barrel 110 and the rotary perforated plate 200. The rotary perforated plate 200 is fixed on the base 100 via a rotating seat. The rotary perforated plate 200 is provided with a positioning seat 210 and a positioning Block 220; such as figure 2 As shown, a plurality of hole groups 201 with different pore diameters are uniformly distributed on the rotary perforated plate 200, and the end surface of the rotary perforated plate 200 facing the positioning seat 210 is also provided with bumps 202 corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com