Anti-electromagnetic spinning roller

An anti-electromagnetic and textile technology, which is applied in the field of textile rollers, can solve the problems of high maintenance cost, high energy consumption, and ineffective anti-electromagnetic protection of textile rollers, and achieve the effects of simple structure, reduced radiation pollution, and good electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

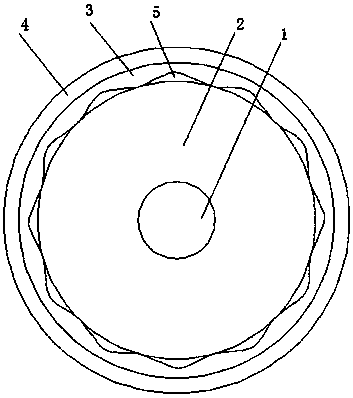

[0016] see figure 1 , the present invention relates to an anti-electromagnetic textile roller, comprising a roller rotating shaft 1 and a roller cylinder 2, the roller rotating shaft 1 is arranged inside the roller cylinder 2, and an elastic layer 3 and a pulling Layer 4, the elastic layer 3 is a rubber layer, and the pulling layer 4 is a steel belt layer.

[0017] Wherein, a plurality of protrusions 5 are provided on the outer peripheral surface of the roller cylinder 2, and the elastic layer 3 is covered on the surface of the protrusions.

[0018] The surface of the roller cylinder 2 is coated with an anti-electromagnetic coating, and the anti-electromagnetic coating contains polymethyl methacrylate resin as a matrix material and mesoporous carbon CMK-3 as a filling material, and the mesoporous The filling amount of carbon CMK-3 is 14-40wt%, wherein the mass percentage is based on the total mass of polymethyl methacrylate resin and mesoporous carbon CMK-3, and the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com