A Method of Indirect Measurement of Filter Branch Current

A technology of branch current and measurement method, which is applied in the direction of measuring device, measuring only current, measuring electrical variables, etc., can solve the problems of high cost, lack of current, and difficulty, so as to reduce costs, avoid hardware modification, and achieve great flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

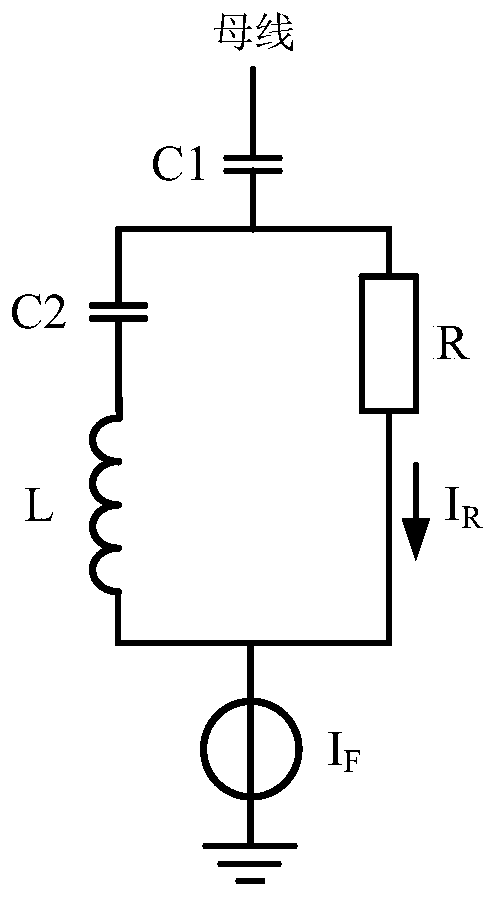

[0011] The indirect measurement method of the filter branch current of the present invention comprises the following steps: (1) determine the topology and circuit parameters of the filter; (2) design a digital filter according to the topology of the filter, and the digital filter is expressed as According to the transfer function of the known current in the measured branch current and the filter, determine the parameters of each part of the digital filter according to the circuit parameters of the filter; (3) according to the digital filter in the step (2) and the filter already Know the measured branch current required for the current solution.

[0012] Attached below figure 1 The present invention is described in detail.

[0013] The topological structure and circuit parameters of the filter can be determined according to the instructions provided by the filter manufacturer or by other means. The topology of the filter in this embodiment includes the first branch, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com