Power battery as well as power battery cover plate and manufacturing method thereof

A technology of power battery and manufacturing method, which is applied in the direction of battery cover/end cover, battery, battery pack parts, etc., can solve problems such as rubber corrosion, battery leakage, and complicated process, and achieve the goal of ensuring reliability and structural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

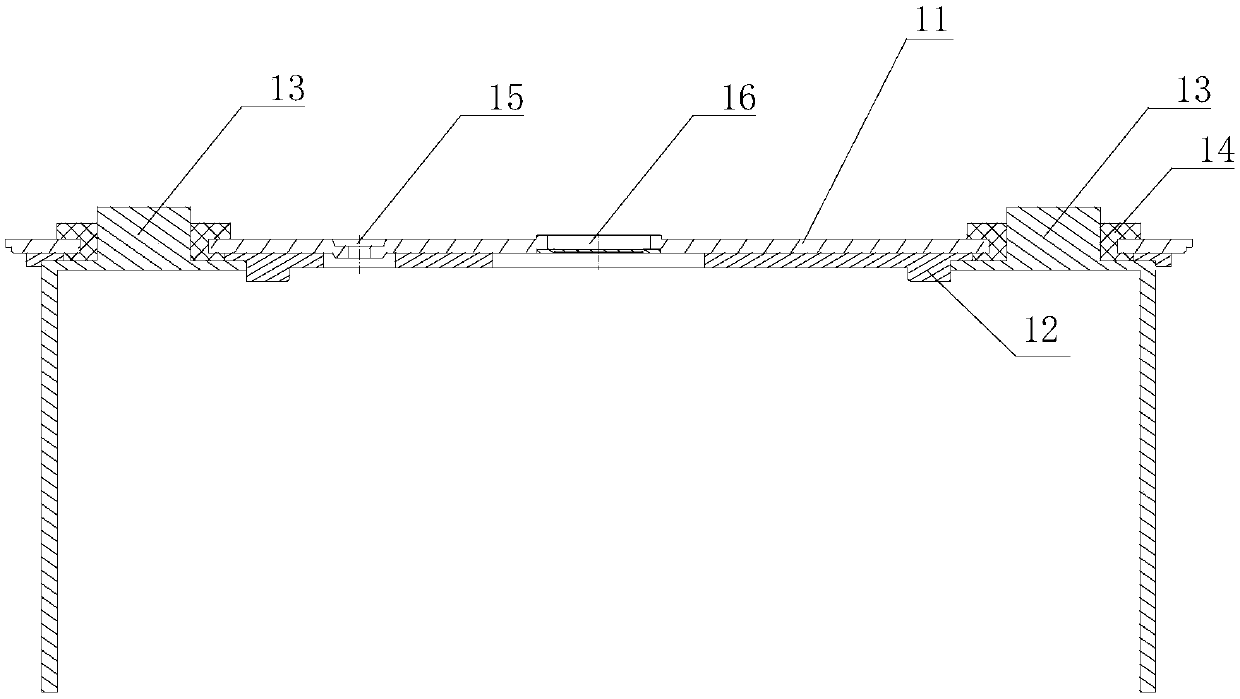

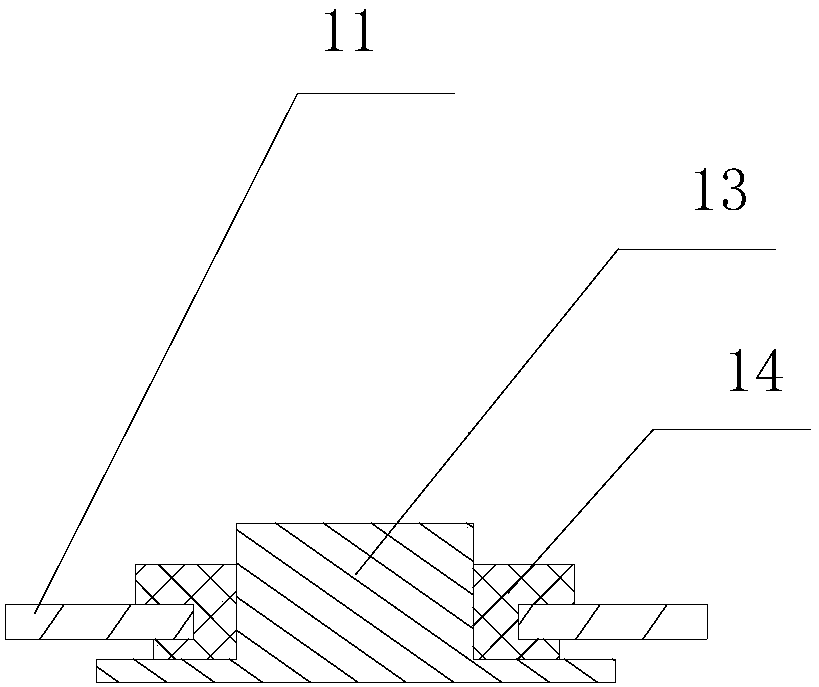

[0015] In one embodiment, such as figure 1 and figure 2 As shown, the power battery cover plate of this embodiment includes a cover plate body 11, an insulating protective layer 12 covering the inner layer of the cover plate body 11, a pole 13 provided through the cover plate body 11, and the pole pole 13 and the cover plate body 11 are formed with an injection molding layer 14 for realizing a sealed connection between the two, a liquid injection hole 15 provided through the cover plate body 11 and used for injecting electrolyte, and a liquid injection hole 15 provided in the cover plate body 11. The explosion-proof device 16 on the plate body 11 is used to discharge the gas inside the battery to release the pressure when the internal pressure of the power battery is high.

[0016] It should be noted that the injection molding layer 14 and the pole post 13 are molded by injection molding and form a chemical bond connection. Furthermore, the cover plate body 11 and the inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com