A cascading submicrosecond-level high voltage pulse generator for vacuum arc-extinguishing chamber aging

A vacuum interrupter, high-voltage pulse technology, applied in electric pulse generator circuits, energy storage elements to generate pulses, and conversion equipment without intermediate conversion to AC, which can solve the impact, increase the cost of primary devices, and affect pulse generation. It can improve the working efficiency of the output pulse front index and other issues, so as to achieve the effect of increasing the amplitude, reducing the working current and working voltage, and satisfying the high repetition rate and long-life operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with accompanying drawing:

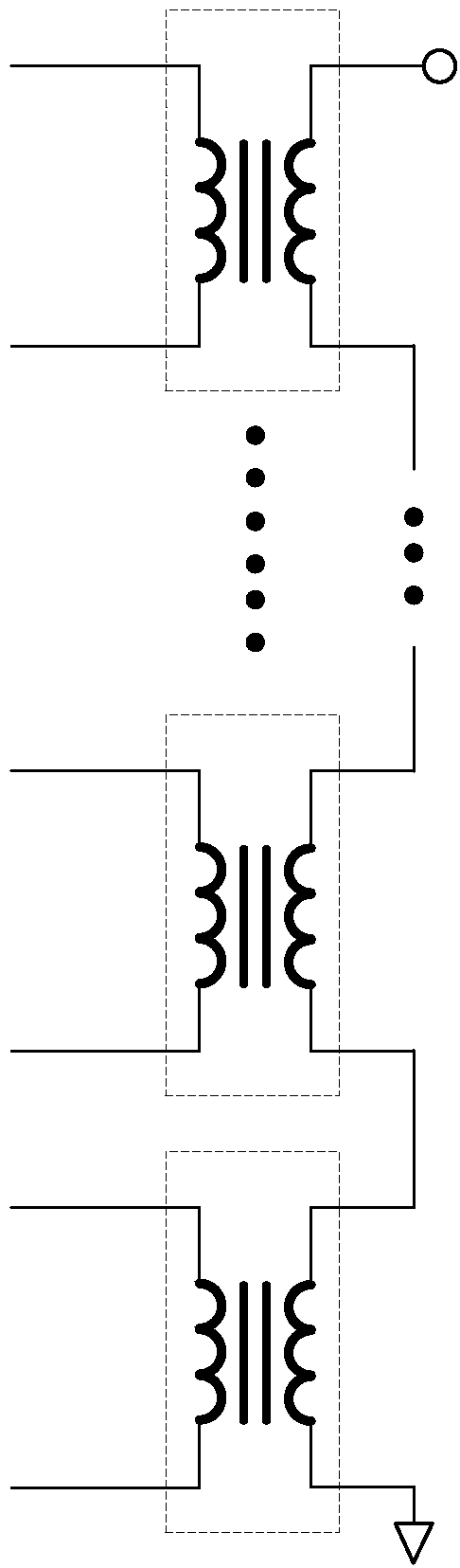

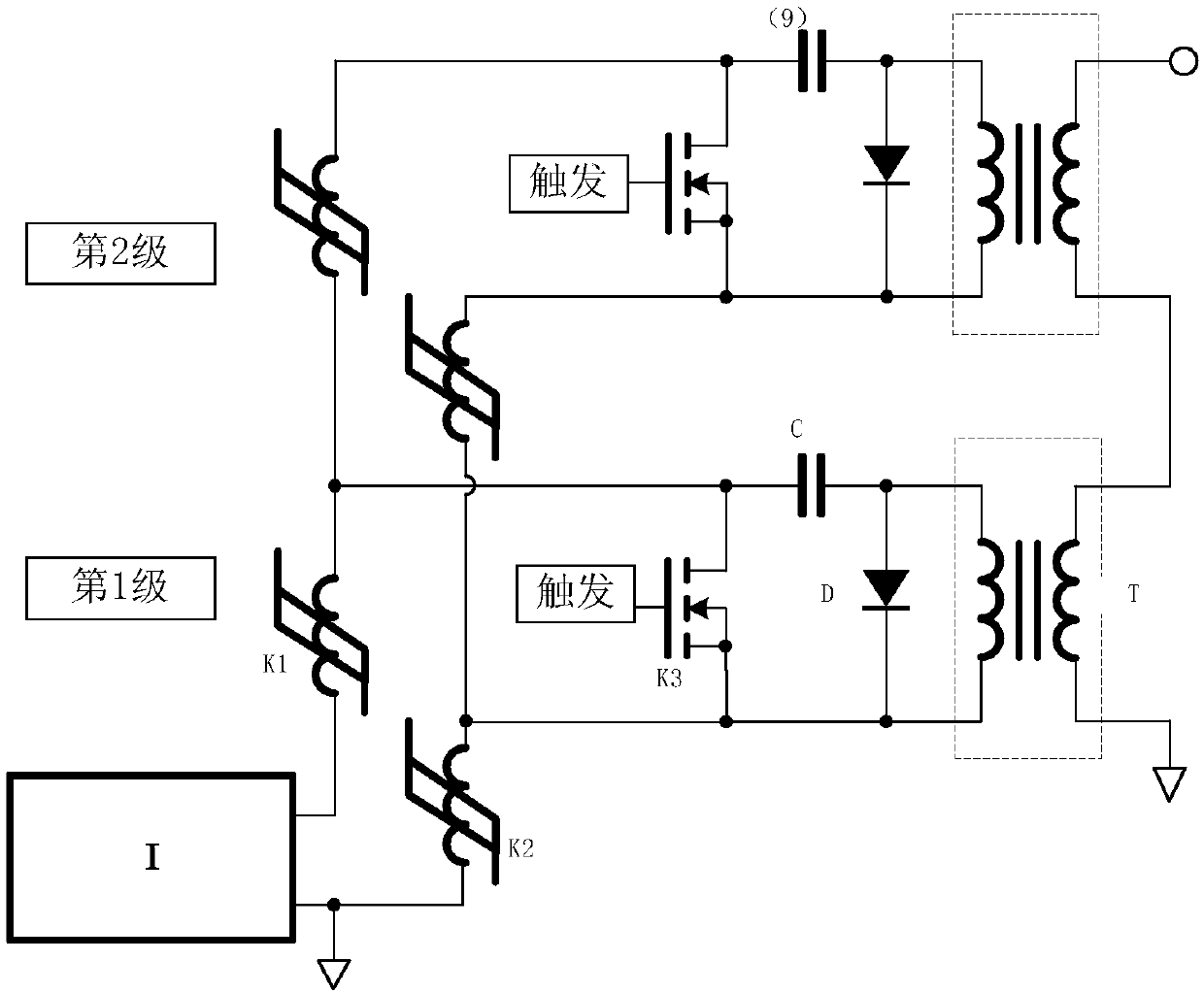

[0015] The cascaded sub-microsecond high-voltage pulse generator used for vacuum interrupter burn-in according to the present invention includes a DC charging power supply I and several pulse transformer assemblies, wherein each pulse transformer assembly includes a pulse transformer T, a freewheeling Diode D, energy storage capacitor C, control switch K3, first magnetic switch K1 and second magnetic switch K2, wherein one end of the primary winding of the pulse transformer T is connected to the anode of the freewheeling diode D and one end of the energy storage capacitor C , the other end of the energy storage capacitor C is connected to one end of the control switch K3 and one end of the first magnetic switch K1, one end of the second magnetic switch K2 is connected to the negative pole of the freewheeling diode D, the other end of the control switch K3 and the pulse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com