Microfluidics chip for detecting mixing with prestored liquid after quantitative flow separation

A microfluidic chip and quantitative shunt technology, which is applied in mixers, laboratory containers, color/spectral characteristic measurement, etc., can solve limitations, affect sample concentration, and cannot accurately design high-precision fluid networks, etc. problem, to achieve quantitative and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

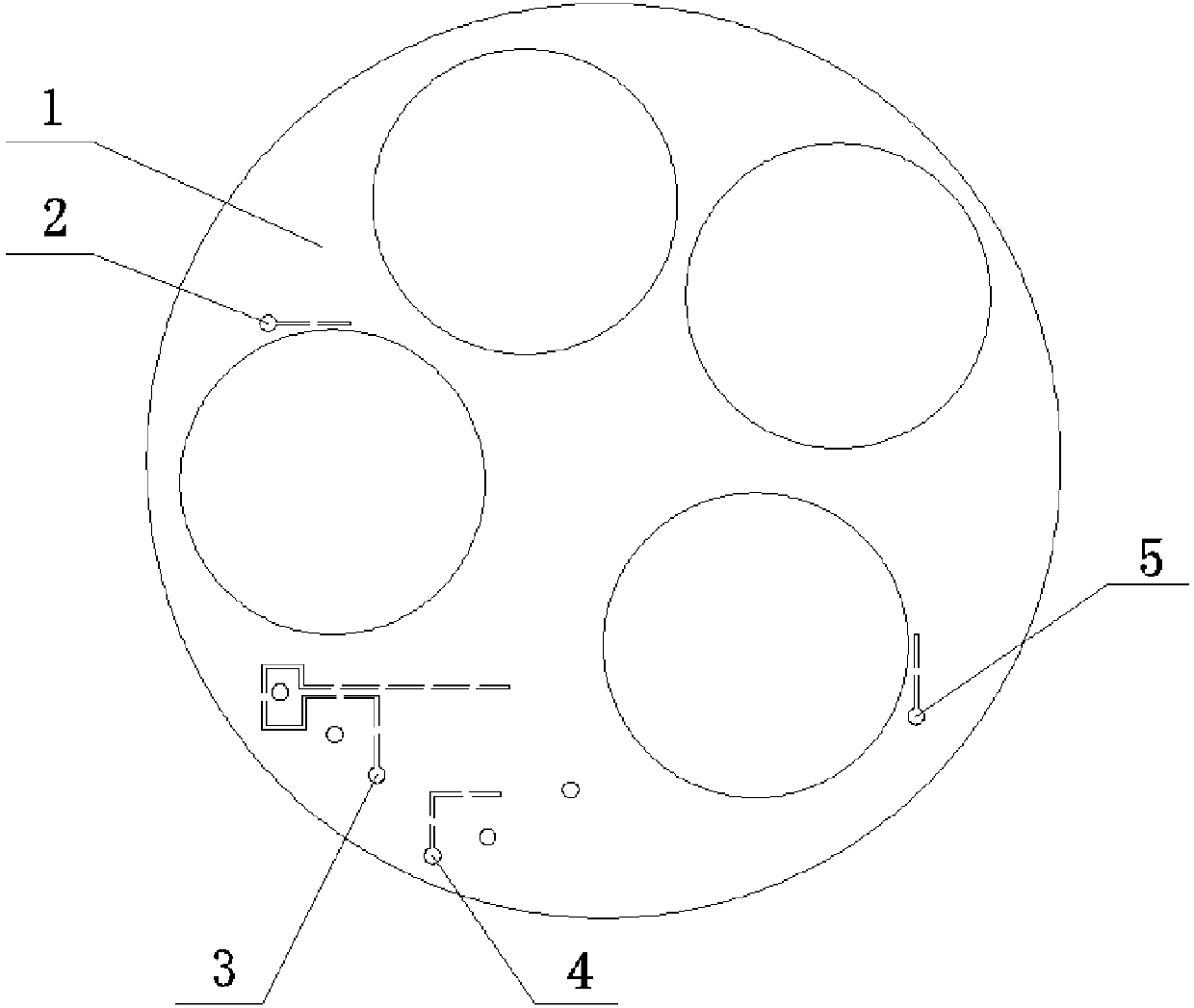

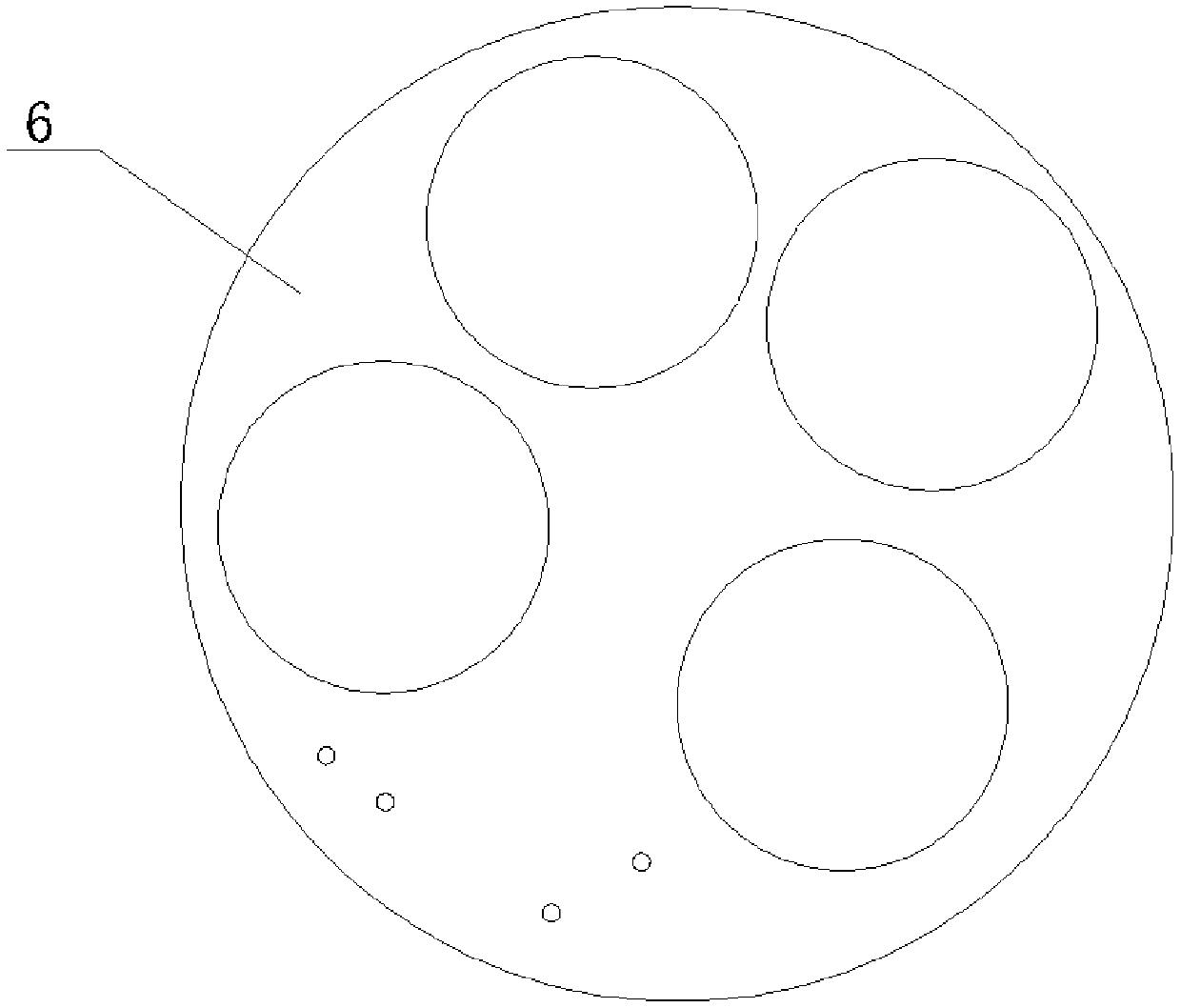

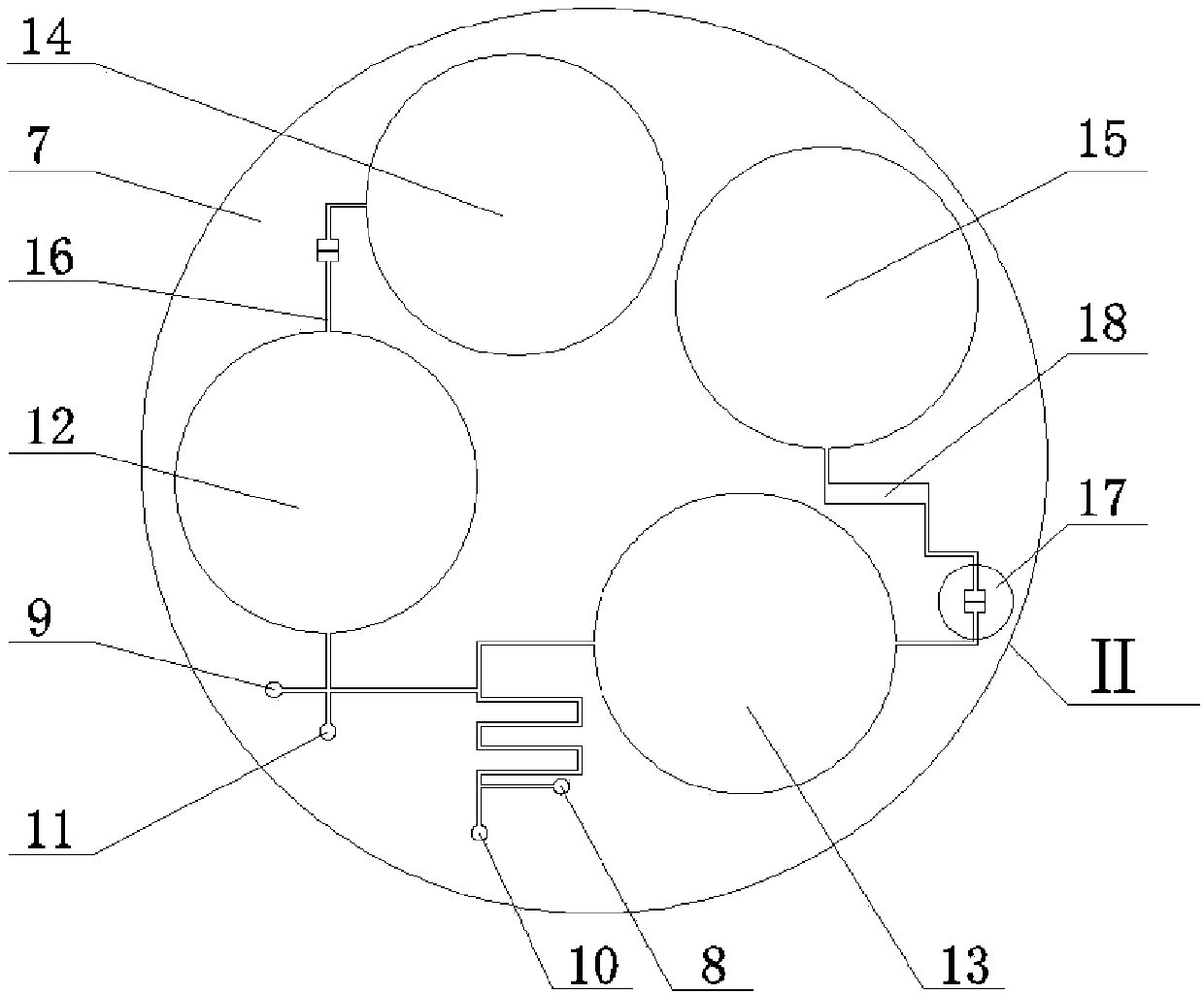

[0022] Such as figure 1 , 2 As shown in , 3, 4, and 5, the present invention provides a microfluidic chip for quantitative shunting and mixed detection with pre-existing liquid. There are three layers in total, including an upper layer cover sheet 1, a middle layer elastic film 6, a lower layer base slice 7. The chip is formed by stacking three layers of chips, and the microfluidic chips of each layer are aligned, bonded, and pressure-sealed to form a three-dimensional microstructure.

[0023] The upper cover sheet 1 includes four pneumatic microvalve control passages 2, 3, 4, 5; the lower layer substrate 7 includes a liquid inlet 8, a liquid outlet 9, a liquid passage inlet 10, 11, the first to the second reservoir Liquid pools 12 , 13 , first to second waste liquid pools 14 , 15 , liquid channel 16 , impedance sensor 17 , and abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com