Cutting part and manufacturing method thereof

A technology for cutting parts and manufacturing methods, which is applied in the manufacturing of tools, tool manufacturing of sawing machines, metal sawing equipment, etc. /High wear resistance, improved service life, good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

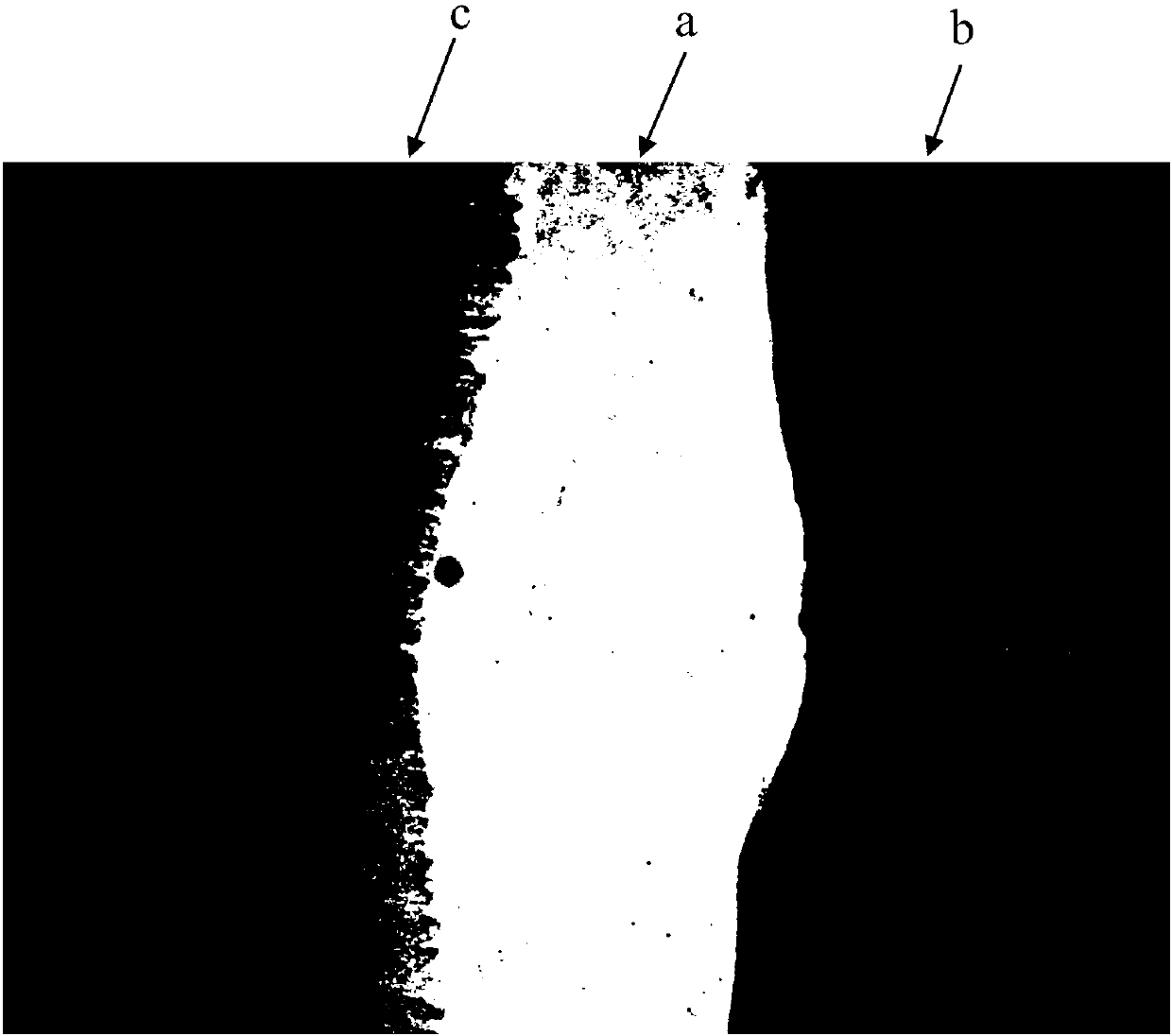

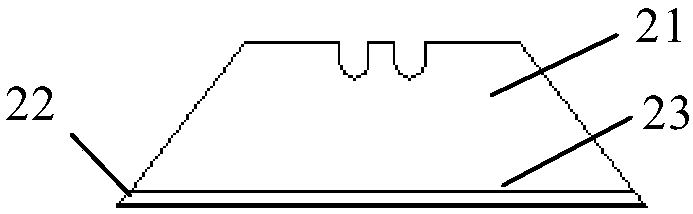

[0072] The cutting component referred to in the present invention is used to cut objects, including a supporting part, a cutting edge part and a weld. The supporting part plays a role of supporting the cutting edge part. The cutting edge part can be used for cutting, and the welding seam is formed by welding. Used to connect the supporting part and the cutting edge part.

[0073] figure 1 The cutting member showing an embodiment of the present invention is a blade. The blade defines a first edge 1, a second edge 2 and a third edge 3, wherein the first edge 1 and the second edge 2 have a first intersection point 11, and the first edge 1 and the third edge 3 have a second intersection point 12 , The second edge 2 and the third edge 3 have a third intersection point 13. In this specific embodiment, the blade has a triangular configuration.

[0074] The blade has a first part 4 for support, and a second part 5 for forming a cutting edge. The first part 4 extends along the second edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com