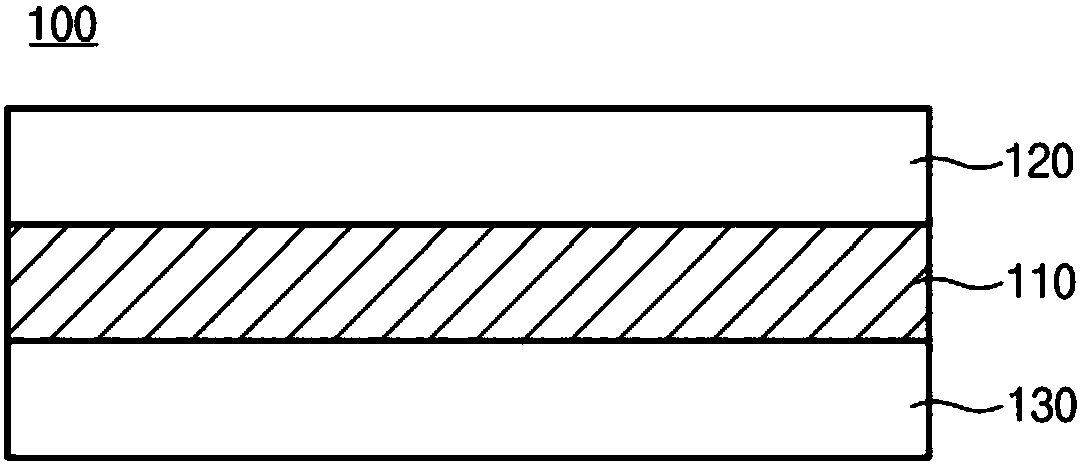

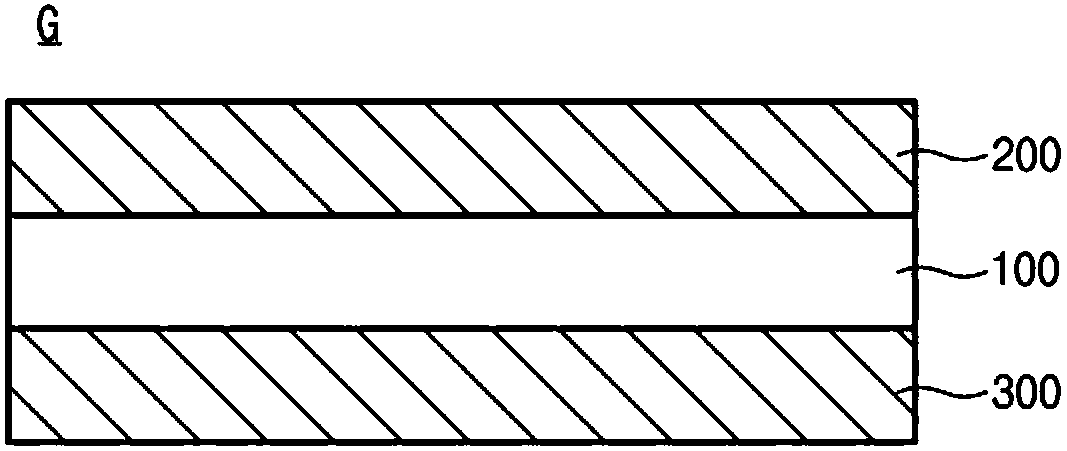

Resin film for laminated glass, laminated glass including the same, and vehicle including the same

A laminated glass and resin film technology, applied in the field of vehicles, can solve the problems of deteriorating the appearance and optical properties of the intermediate layer and laminated glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] 1) Prepare the first polyvinyl acetal resin (B)

[0119] 190 g of polyvinyl alcohol having a degree of polymerization of 1,700 was used in 2,910 g of pure water and dissolved while raising the temperature. The reaction system was adjusted to 12° C., and 201 g of 35% by weight hydrochloric acid and 124 g of butyraldehyde were used to precipitate polyvinyl acetal. Thereafter, the reaction system was kept at a temperature of 50° C. for 4 hours, and the reaction was completed. The resulting material was washed with excess water to wash away unreacted aldehyde. Then, the resulting substance was neutralized with a hydrochloric acid catalyst to remove salts, and dried to obtain a first polyvinyl acetal resin (B) as a white powder. The degree of acetalization of the obtained first polyvinyl acetal resin (B) was 65.9 mol %, and the acetyl group content was 0.9 mol %.

[0120] 2) Preparation of the second polyvinyl acetal resin (A)

[0121] 191 g of polyvinyl alcohol having a...

Embodiment 2

[0132] Laminated glass was prepared by the same method as in Example 1, except for using the second resin composition prepared as follows and adjusting the surface roughness of the second resin layer and the third resin layer to 22 μm. 61.35g of the second polyvinyl acetal resin (A), add and mix 36g of triethylene glycol-di-2-ethylbutyrate as the second plasticizer, 2g as the second ethylene-α-olefin copolymer MITSUI EXCEREX TM , 0.5 g of trimethoxy(octyl) silane as the second silane compound and 0.15 g of tetrakis[methylene-3-(3',5'-butyl-4'-hydroxyphenyl) as antioxidant propionate] methane, followed by an intensive roll-mix-mill mixture using mixing rollers.

experiment Embodiment 1

[0135] [Experimental Example 1] Measurement of Maximum Static Friction Coefficients of Second Resin Layer and Third Resin Layer

[0136] The resin film was mounted on a horizontal SUS board, a plane weight of 65 x 65 mm (500 g) was mounted thereon, and the SUS board was tilted to measure the angle at which the plane weight slides. The measured angles were converted into coefficients of friction, and the results are shown in Table 1.

[0137] [Table 1]

[0138]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com