High-stability, short-flame, low-NOx and low-CO combustor

A high-stability burner technology, applied in CO burners, burners, and low NOx fields, can solve problems such as poor mixing of fuel gas and air, reduced power of fuel gas injection, and reduced heat absorption in the radiant section. Promote flame forming, increase air velocity, and promote the effect of ejection and guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

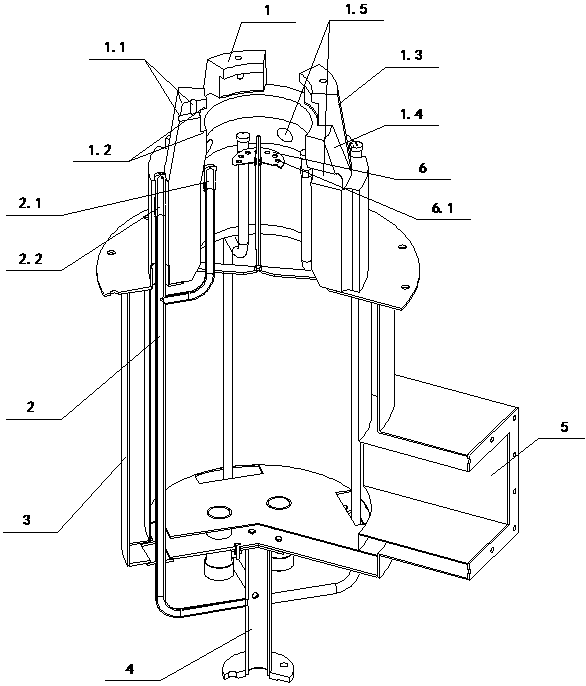

[0032] see figure 1 , The present invention relates to a high stability, short flame low NOx, CO burner, which includes refractory brick 1, Y-shaped air gun 2, shell 3, air collecting pipe 4, air inlet 5 and throat plate 6.

[0033] The refractory brick 1 includes a first refractory brick 1.3 and a second refractory brick 1.4, the slope of the first refractory brick 1.3 is a slope with a large inclination angle, and the slope is 60°~85°, and the slope of the second refractory brick 1.4 is a slope with a small slope angle. The inclination angle is 45°~70°. The first refractory brick 1.3 and the second refractory brick 1.4 form a group, and there are 2-20 groups in total. The inner side of the first refractory brick 1.3 has a concave flame-stabilizing ring 1.2. The first refractory brick The brick 1.3 is provided with mutually perpendicular flame-stabilizing holes 1.1, and the flame-stabilizing holes 1.1 are provided with 4-100 groups. There are radial flue gas return holes 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com