A kind of microchannel reactor, device and preparation method of 5-fluorocytosine

A micro-channel reactor and micro-channel reaction technology, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, organic chemistry, etc. The problems such as low total yield of the synthetic route can achieve the effects of reducing the generation of by-products, making it convenient and simple in structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

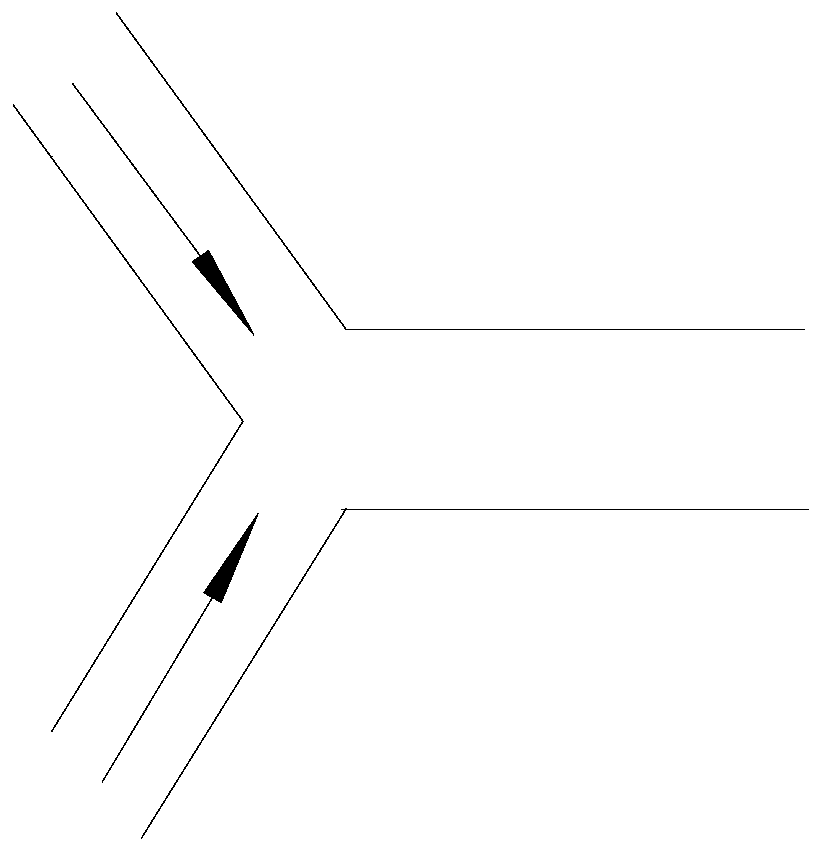

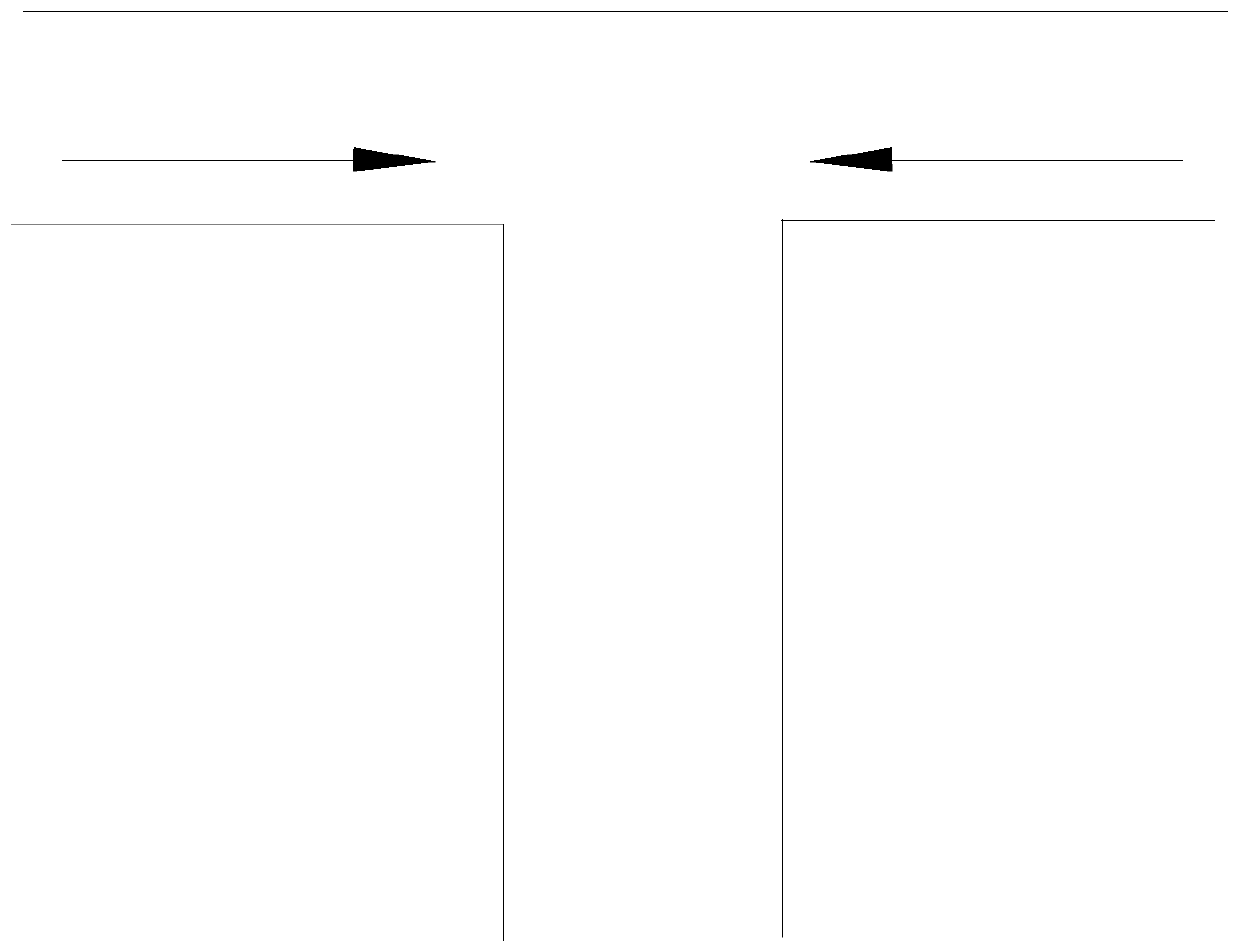

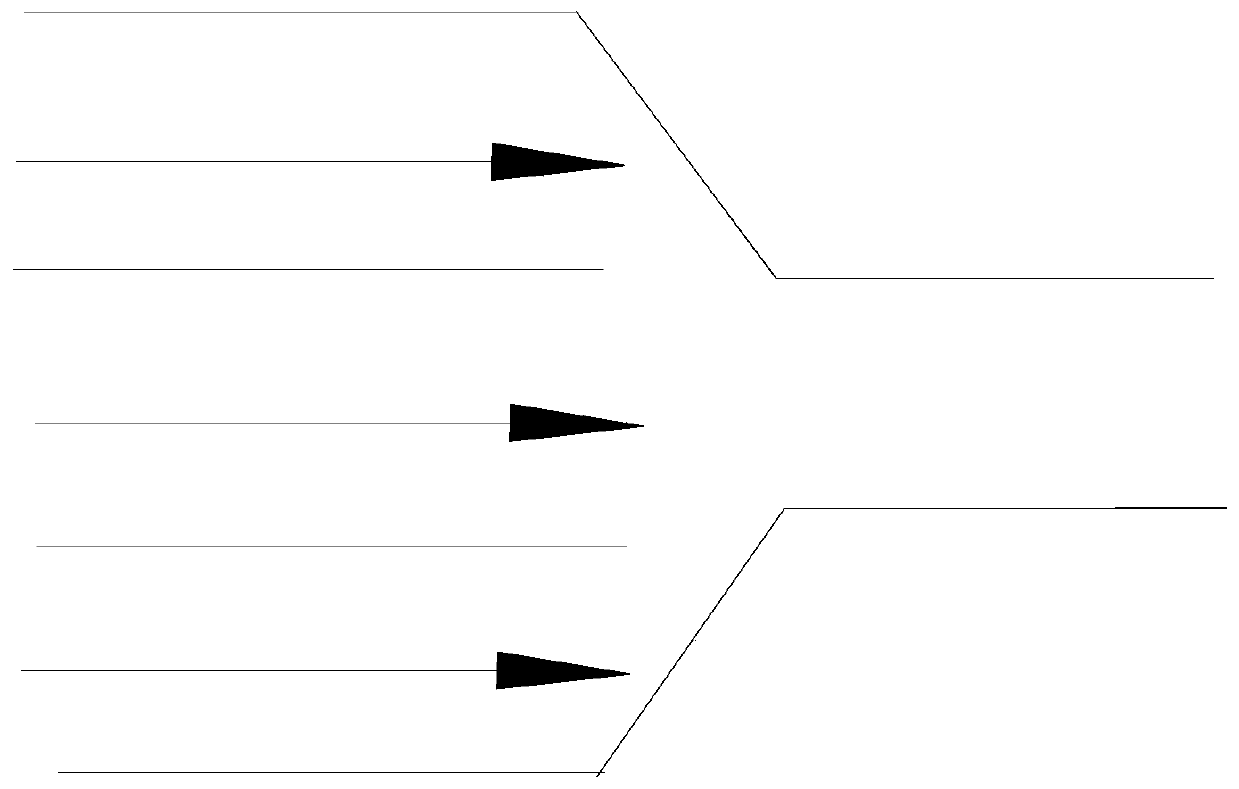

Image

Examples

Embodiment 1

[0076] After dissolving 44.4g of cytosine with 200ml of anhydrous hydrofluoric acid, a cytosine solution with a concentration of 2mol / L was obtained. After filtering with a special acid-resistant filter membrane, it entered the microchannel reaction device through a mass flow valve at a flow rate of 5ml / L. h, feed fluorine gas content through the gas flowmeter and be that the fluorine gas of 15%, nitrogen mixed gas enters the microchannel reaction device, flow rate is 50ml / min, reaction constant temperature is at-15 ℃, and total residence time is 15min, gets crude product, The content of 5-fluorocytosine is 95%, using CaCO 3 Neutralize excess acid, adjust Ph value at 7-8, remove CaF by hot filtration at 70°C 2 , after decolorization and drying by activated carbon, white blocky 5-fluorocytosine was obtained, the purity was 99.1% and the yield was 85% as determined by liquid chromatography mass spectrometry.

Embodiment 2

[0081] Dissolve 22.2g of cytosine with 200ml of formic acid to obtain a 1mol / L cytosine solution, which is filtered by a special filter membrane for liquid phase to prevent insoluble impurities from clogging the microchannel during sample injection, and enters the microchannel reaction device through a mass flow valve In the process, the flow rate is 5ml / h, the microchannel reaction device is passed into the mixed gas of fluorine gas and nitrogen gas with a fluorine content of 20%, the flow rate is 50ml / min, the reaction temperature is controlled at -20°C, and the residence time is 10min to obtain the crude product , wherein the content of 5-fluorocytosine is 90%, with weakly alkaline NaHCO 3 After neutralizing excess acid, NaF was removed by recrystallization, and after drying at 105° C., blocky 5-fluorocytosine was obtained with a purity of 99.5% and a yield of 85% as determined by liquid chromatography mass spectrometry.

Embodiment 3

[0083] After dissolving 22.2g of cytosine with 200ml of formic acid, a 1mol / L cytosine solution was obtained. After filtering with a special filter membrane for liquid phase, it entered the microchannel reaction device through a mass flow valve with a flow rate of 5ml / h. Microchannel reaction The device was fed with a mixed gas of fluorine and nitrogen with a fluorine content of 10%, the flow rate was 50ml / min, the reaction constant temperature was at -20°C, and the residence time was 10min to obtain a crude product, wherein the 5-fluorocytosine content was 81%. Weakly alkaline NaHCO 3 After neutralizing excess acid, NaF was removed by recrystallization, and after drying at 105° C., blocky 5-fluorocytosine was obtained with a purity of 99% and a yield of 75% as determined by liquid chromatography mass spectrometry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com