Wire arch detecting method and device in photovoltaic silicon wafer cutting process

A technology for silicon wafer cutting and process detection, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve the problems of inconvenient operation and insufficient precision, and achieve the effect of accurate results, continuous observation, and reduced detection difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

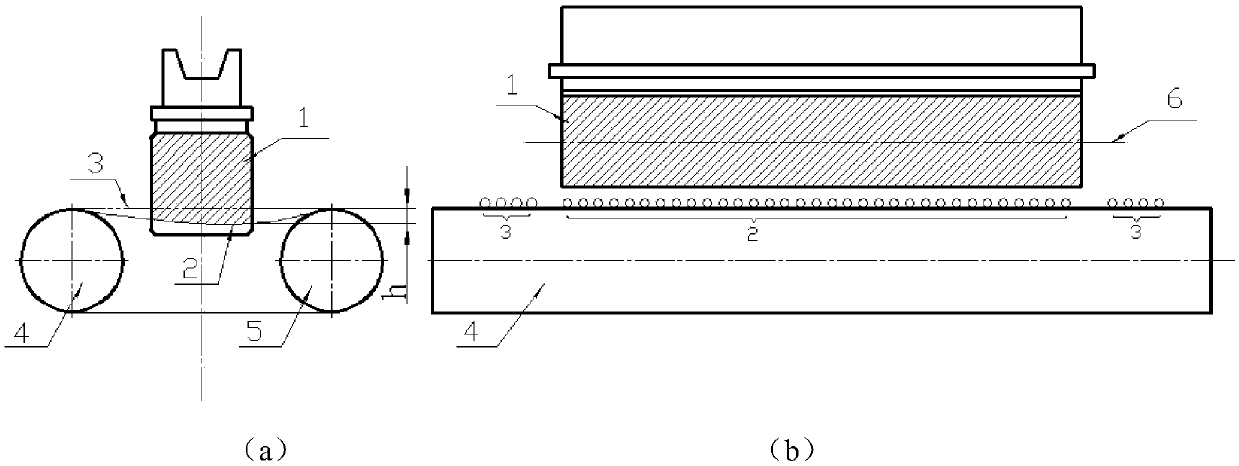

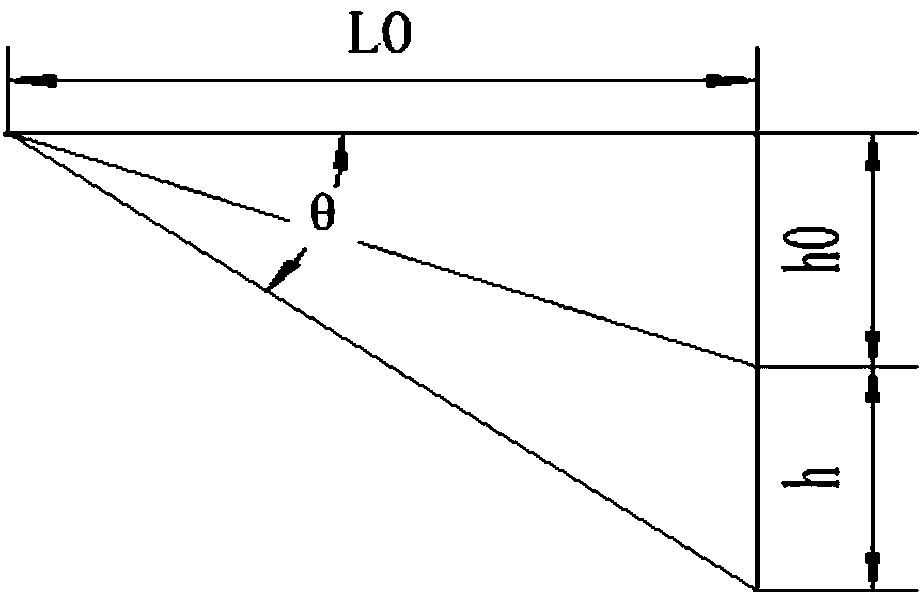

[0034] Such as figure 1 As shown, the essence of line bow measurement is to measure a longitudinal height h.

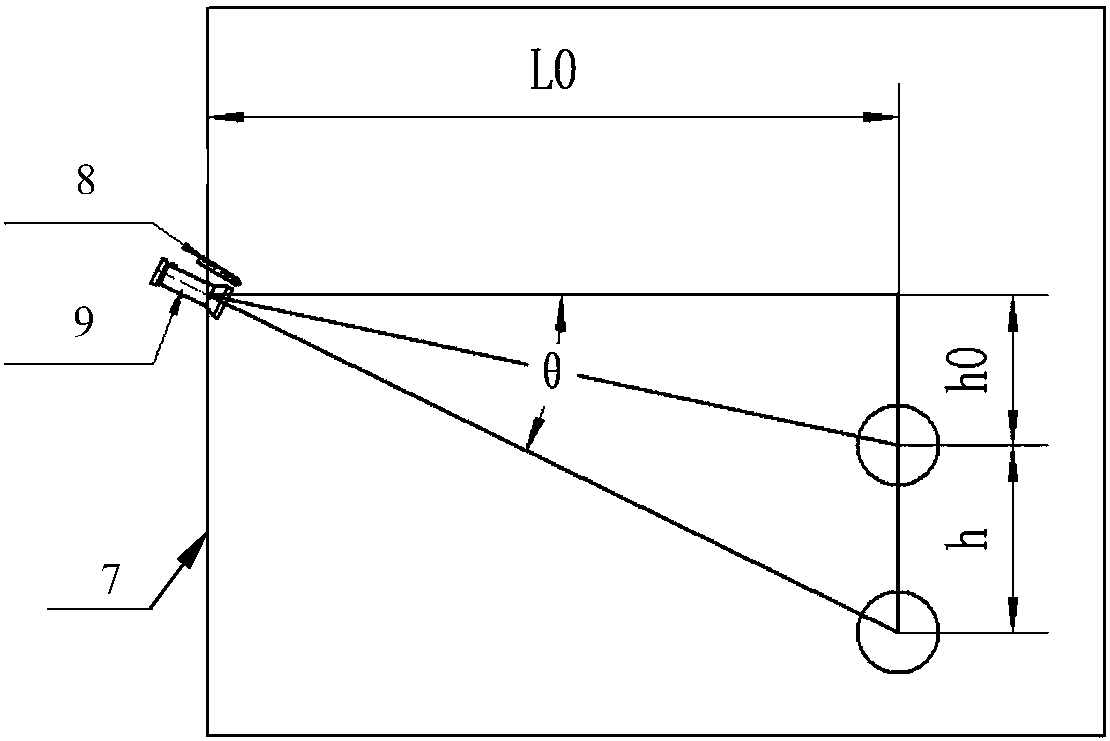

[0035] Such as image 3 As shown, in this embodiment, an independent detection device is set on the cutting chamber wall 7 of the multi-wire cutting machine, that is, a telescopic lens 8 with a transparent scale outside, and a cross mark in the center of the lens. There is a protective cover in front of the lens, open the protective cover before measurement.

[0036] Small-sized lighting fixture 9 and switch are installed in front of the camera lens to provide illumination for observation; the lamp has a protective cover, and the protective cover is opened when the switch is turned on.

[0037] The telephoto lens and lighting fixtures are removable and washable.

[0038] The detection process is as Figure 5 Shown:

[0039] Firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com