Herringbone hanging bracket disassembling method

A herringbone and hanger technology, applied in the direction of load hanging components, cranes, hoisting devices, etc., can solve the problems of low utilization rate, achieve the effect of small impact, reduce resistance, and protect the bottom of the strut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

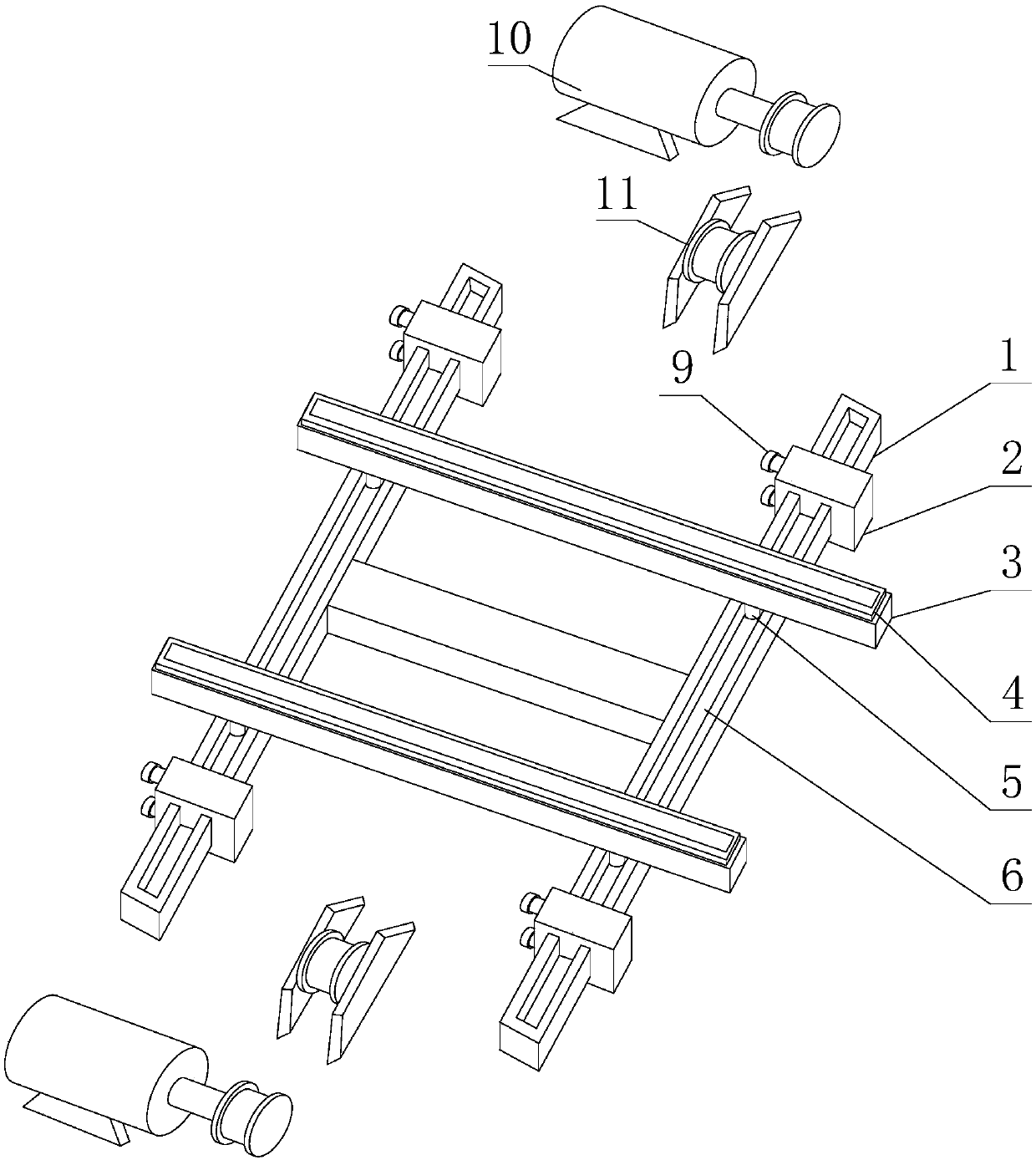

[0038] Such as figure 1 and figure 2 As shown, a method for decomposing a herringbone hanger, the method uses the following device to realize the decomposition of a herringbone hanger, and the form of the hanger is that the legs of the hanger are a multi-section combined structure, and each rod forming the legs The connection form between the segments is a detachable connection form: the device includes two mutually parallel turning tanks 4, and each turning tank 4 is provided with a strip-shaped second and parallel to the length direction of the turning tank 4. Groove 8, the opening end of the second groove 8 faces upward;

[0039] It also includes two hoisting machines 10, and two turning tanks 4 are located between the two hoisting machines 10;

[0040] The implementation steps of the decomposition method are:

[0041] S1. Fix two stay ropes on the top of the hanger, and the above two stay ropes are respectively wound on different winches 10;

[0042] S2. The hanger is...

Embodiment 2

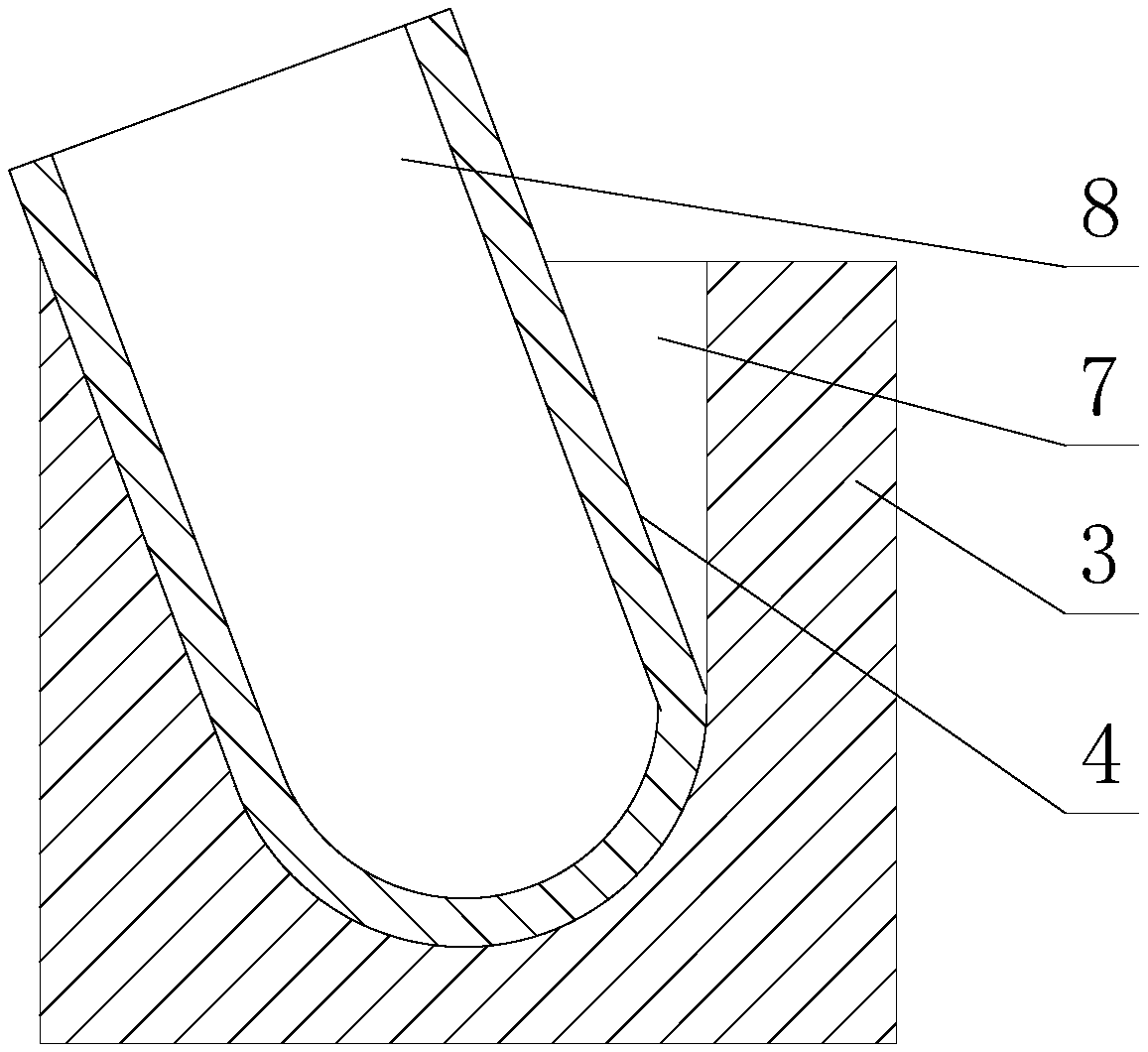

[0047] Such as figure 1 and figure 2 As shown, the present embodiment is further limited on the basis of Embodiment 1: it also includes strip-shaped turning seats 3, the number of said turning seats 3 is two, and the turning seats 3 are parallel to each other, and each turning seat 3 are provided with a first groove 7 parallel to the length direction of the flip seat 3, and the opening ends of the first groove 7 are all upward;

[0048] Two turning grooves 4 are respectively installed in different first grooves 7, the turning grooves 4 are parallel to the turning seat 3, and the width of the opening end of each first groove 7 is greater than the width of the inner turning groove 4 , the bottom of each first groove 7 is in contact with the bottom of the inner turning tank 4, and each turning tank 4 can swing in the corresponding first groove 7 with its own bottom as the center of rotation. Since the turning tank body 4 can swing in the first groove 7, the turning tank body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com