High-transmittance and high-infrared-penetration functional silicate glass, preparation method thereof and application of glass

A technology of silicate glass and high light transmittance, applied in the field of silicate glass, can solve the problems of reduced photoelectric conversion efficiency, poor transmittance, high heat absorption of glass, etc., and achieve excellent light transmittance and high transmittance Infrared performance, not easy to heat deformation and heat shrinkage, and the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

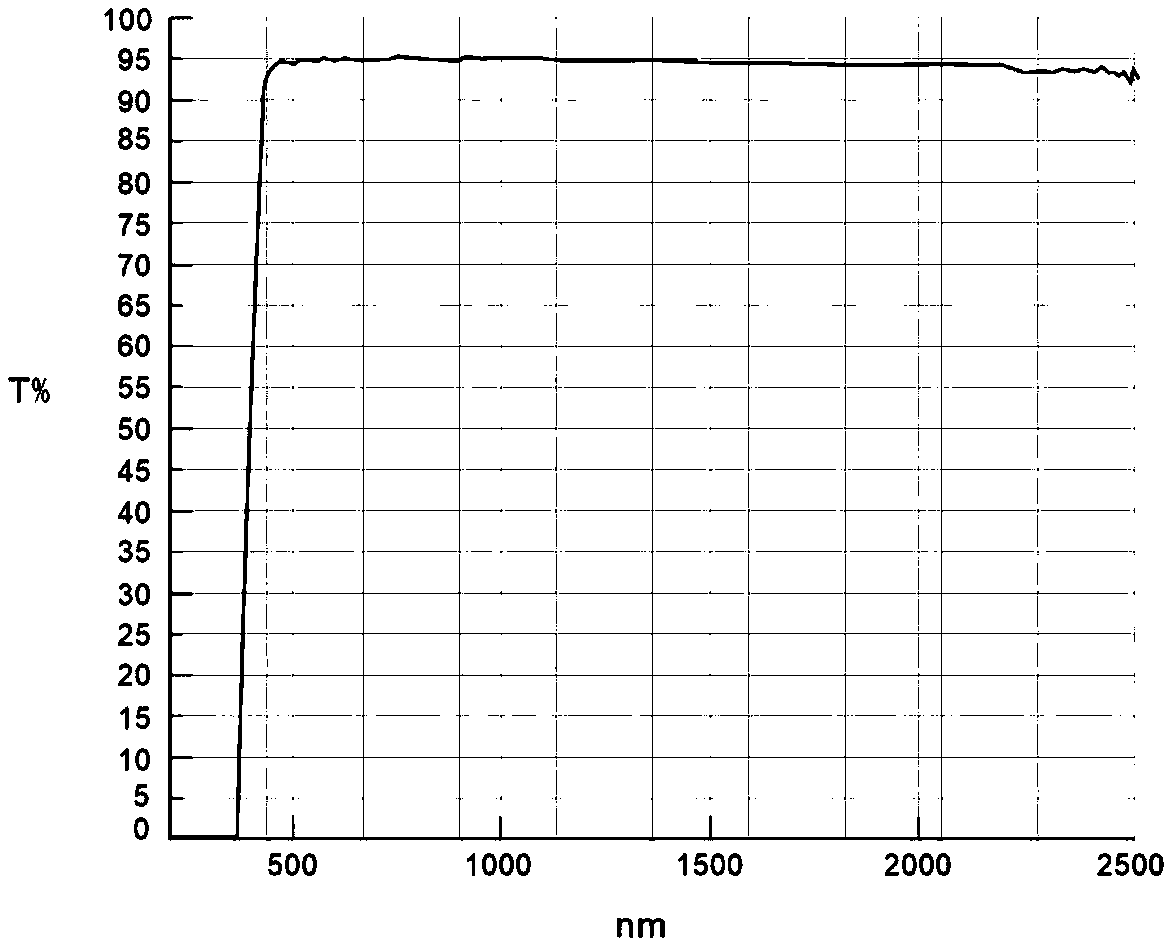

Embodiment 1

[0060] Taking the preparation of silicate (soda lime) glass with a thickness of 1.5mm and high light transmittance and high infrared transmittance as an example, add 500 grams of the following ingredients to a zirconia crucible with a capacity of 1000 grams and a temperature resistance of 2000 ° C:

[0061] Basic ingredients: quartz sand: 342 grams, soda ash: 120 grams, Glauber's salt: 6 grams.

[0062] High light transmittance, high infrared transmittance coordinating agent part: 36 grams of each element composition on demand: (CeO 2 : 0.6 g; CaF 2 : 28.5 g; KOH: 1 g; B 2 o 3 : 1 g; Al(OH)3: 4 g, carbon powder: 0.9 g.

[0063] Mix the above raw materials evenly, control the melting temperature to 1550°C, heat to 1500°C, keep it for about 30 minutes, then raise the temperature to 1550°C, keep it for about 60 minutes, then carry out clarification and homogenization, and the clarification temperature is decreased from 1450°C It takes about 30 minutes to reach 1300°C. Finally...

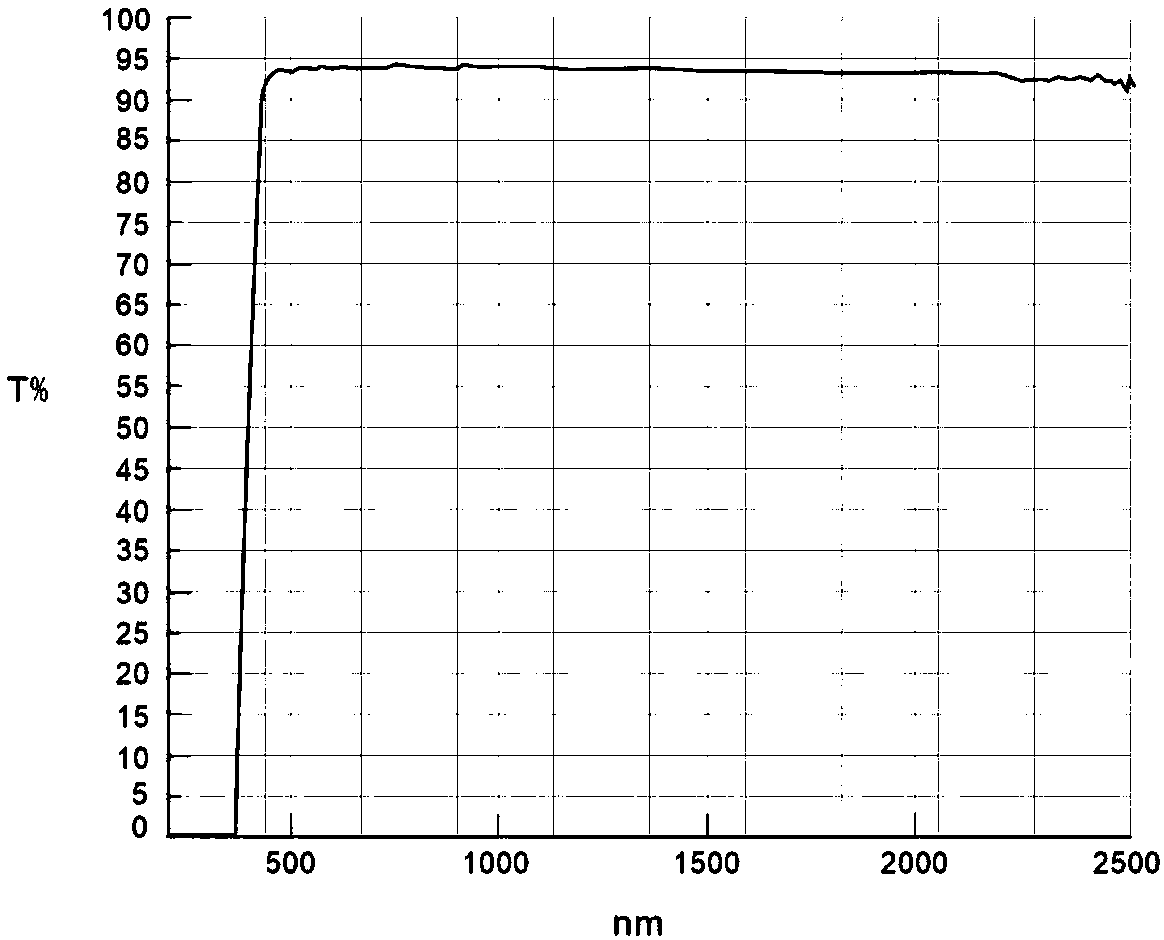

Embodiment 2

[0068] Taking the preparation of 2.5mm thick silicate (soda lime) glass with high light transmittance and high infrared transmittance as an example, add 500 grams of the following batch ingredients to a zirconia crucible with a capacity of 1000 grams and a temperature resistance of 2000 ° C:

[0069] Basic ingredients: quartz sand: 345 grams, soda ash: 120 grams, Glauber's salt: 6 grams.

[0070] High light transmittance, high infrared transmittance coordinating agent part: 31 grams of each element composition on demand: (CeO 2 : 0.8 g; CaF 2 : 25 grams; KOH: 0.8 grams; B 2 o 3 : 1.5 g; Al(OH) 3 : 2g, Toner: 0.9g.

[0071] Mix the above raw materials uniformly to control the redox ratio, control the melting temperature to 1550°C, heat to 1500°C, keep it for about 30 minutes, then raise the temperature to 1550°C, keep it for about 60 minutes, then carry out clarification and homogenization, the clarification temperature It takes about 30 minutes to drop from 1450°C to 1300...

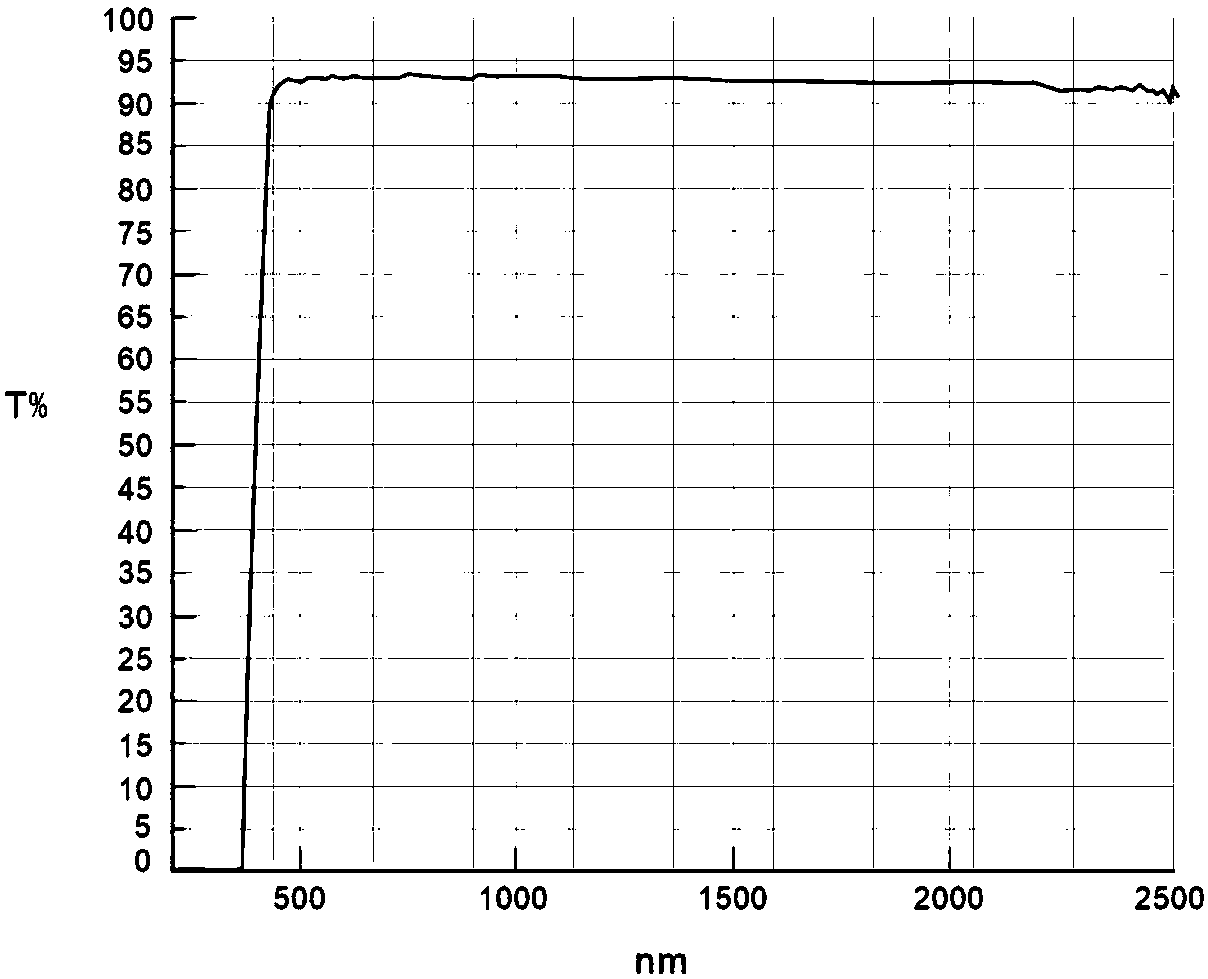

Embodiment 3

[0074] Taking the preparation of silicate (soda lime) glass with a thickness of 3.5mm and high light transmittance and high infrared transmittance as an example, add 500 grams of the following batch ingredients to a zirconia crucible with a capacity of 1000 grams and a temperature resistance of 2000 ° C:

[0075] Basic ingredients: quartz sand: 340 grams, soda ash: 120 grams, Glauber's salt: 6 grams.

[0076] High light transmittance, high infrared transmittance coordinating agent part: 34 grams of each element composition on demand: (CeO 2 : 1 g; CaF 2 : 30g; KOH: 1g; B 2 o 3 : 1 g; Al(OH) 3 : 3g, Toner: 1g.

[0077] Mix the above raw materials evenly, control the melting temperature to 1550°C, heat to 1500°C, keep it for about 30 minutes, then raise the temperature to 1550°C, keep it for about 60 minutes, then carry out clarification and homogenization, and the clarification temperature is decreased from 1450°C It takes about 30 minutes to reach 1300°C. Finally, the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com