Method for coupling propane dehydrogenation technology and deethanization technology before naphtha cracking

A technology for propane dehydrogenation and naphtha, which is applied in the direction of hydrocarbons, hydrocarbons, chemical instruments and methods, and can solve the problems of low production of low-carbon olefins, large equipment footprint, and high project investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

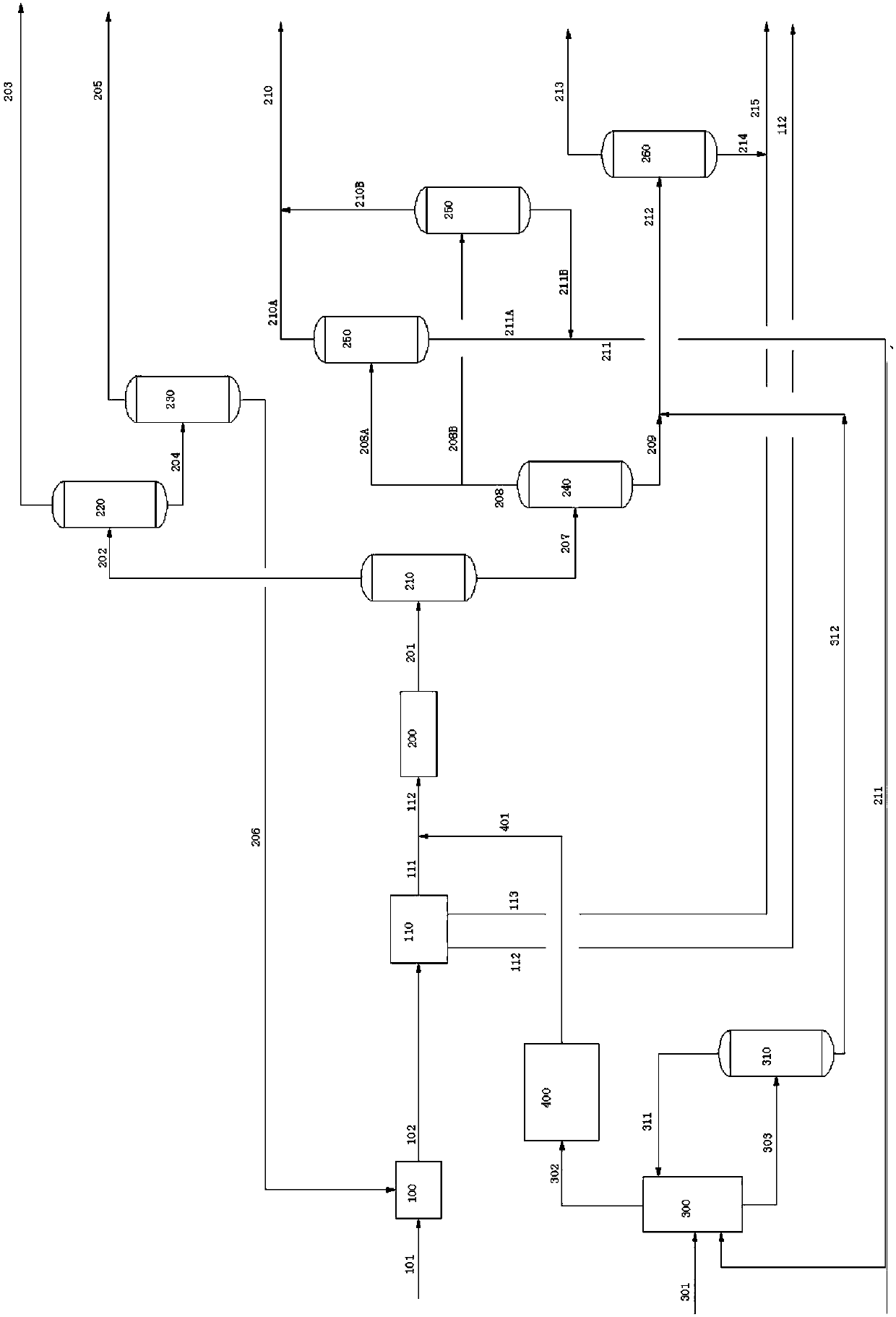

[0027] The present invention relates to a coupling method of PDH process and deethanization process before naphtha cracking. Technical problems such as low olefin yield. Provide a new type of olefin separation integration process for PDH unit and ethylene unit. On the premise of keeping the cracking raw materials of the ethylene unit unchanged, based on the partial capacity expansion and transformation process of the existing separation equipment for deethanization before the ethylene unit, only Add one PDH reaction system and one C3 separation system, which can be highly integrated with the deethanization separation process before the ethylene plant, combined into a new coupling method of "two heads, one tail", which has the advantages of process It has the advantages of simple process, high equipment utilization rate, low project investment cost, small equipment footprint, and can increase the production of low-carbon olefins such as ethylene propylene, and can avoid the cos...

Embodiment 2

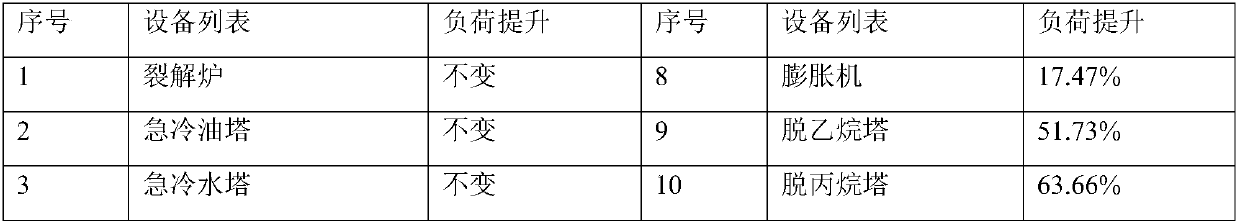

[0043] The PDH process of the present invention is coupled with the deethanization process before naphtha cracking, the ethylene unit adopts the pre-deethanization separation process, the nominal capacity is 1 million tons / year, and the cracking selectivity P / E=0.55; the PDH unit The nominal capacity is 600,000 tons / year.

[0044] Table 3 Raising load table of original ethylene equipment after integration

[0045]

[0046]

[0047] Therefore, polymer grade ethylene ≥ 99.95wt%, ethylene output is 1.0197 million tons / year; polymer grade propylene is ≥99.6wt%, propylene output is 1.069 million tons / year, and the engineering construction investment of ethylene unit and PDH unit process coupling is 6.661 billion yuan . Compared with the existing ethylene plant in [Comparative Example 2], the ethylene output increased by 1.970%, the propylene output increased by 94.364%, and the project construction investment was saved by 558 million yuan, which is equivalent to saving inves...

Embodiment 3

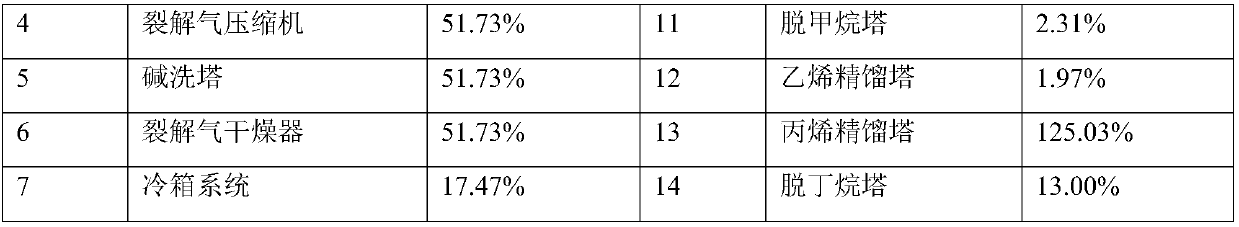

[0051] The PDH process of the present invention is coupled with the deethanization process before naphtha cracking, the ethylene unit adopts the pre-deethanization separation process, the nominal capacity is 1.1 million tons / year, and the cracking selectivity P / E=0.55; the PDH unit The nominal capacity is 600,000 tons / year.

[0052] Table 4 Lifting load table of original ethylene equipment after integration

[0053] serial number

[0054] Thus, polymer grade ethylene ≥ 99.95wt%, ethylene output 1,119,700 tons / year; polymer grade propylene ≥99.6wt%, propylene output 1,124,000 tons / year, engineering construction investment of ethylene unit and PDH unit process coupling 6.929 billion yuan . Compared with the existing ethylene plant in [Comparative Example 3], the ethylene output increased by 1.791%, the propylene output increased by 85.785%, and the project construction investment was saved by 571 million yuan, which is equivalent to saving investment by 7.609%, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com