A kind of super amphiphilic polyurethane foam material and preparation method thereof

A technology of polyurethane foam and polyurethane sponge, which is applied in the direction of coating, etc., can solve the problems of complex operation process of hydrothermal method and difficult control of sample size, and achieve the effect of reusability, overcapacity problem and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

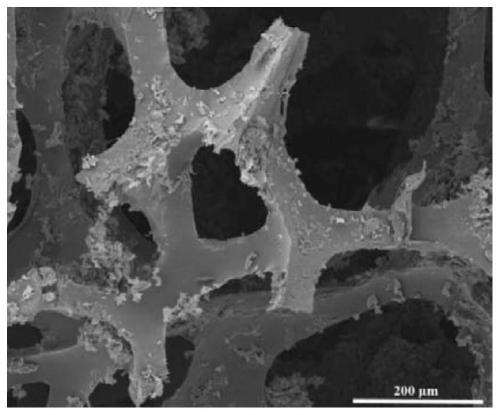

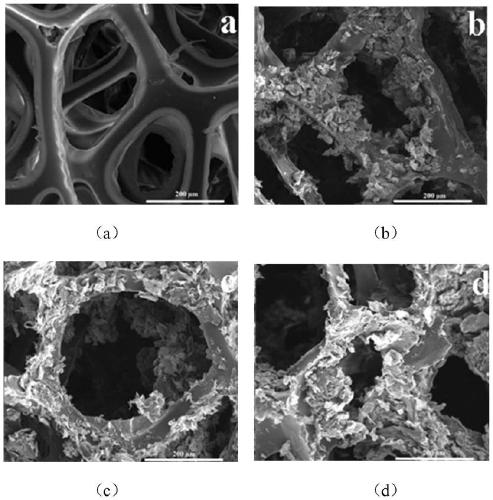

[0033] The process of preparing the super-amphiphilic polyurethane foam material in this example is to pre-coat nano-cellulose and then dip-coat graphene, wherein the nano-cellulose is prepared by chemically hydrolyzing corn stalks. The specific process is as follows:

[0034] Put the nanocellulose into a beaker, add tap water to make it up to volume, and ultrasonically treat it for 60 minutes under the condition of a power of 500W to obtain a uniform nanocellulose aqueous dispersion, wherein the nanocellulose content is 0.5wt%.

[0035] Soak the cleaned and dried polyurethane sponge in the nanocellulose aqueous dispersion for 30 minutes, take it out and fully dry it in an oven at 40°C to obtain a polyurethane sponge coated with nanocellulose. Then soak the polyurethane sponge coated with nanocellulose in the graphene dispersion (1 g graphene / 800 mL water) for 40 min, and then dry it at 20 ° C to obtain a super-amphiphilic polyurethane foam.

Embodiment 2

[0037] The process of preparing the super-amphiphilic polyurethane foam material in this example is to pre-coat nano-cellulose and then dip-coat graphene, wherein the nano-cellulose is prepared by chemically hydrolyzing wood powder. The specific process is as follows:

[0038] Put the nanocellulose into a beaker, add deionized water to make it up to volume, and ultrasonically treat it for 30 minutes under the condition of a power of 600W to obtain a uniform nanocellulose aqueous dispersion, wherein the nanocellulose content is 0.6wt%.

[0039] Soak the cleaned and dried polyurethane sponge in the nanocellulose aqueous dispersion for 40 minutes, take it out and fully dry it in an oven at 50°C to obtain a polyurethane sponge coated with nanocellulose. Then soak the polyurethane sponge coated with nanocellulose in the graphene dispersion (1g graphene / 300mL water) for 60min, and then dry it at 40°C to obtain a super-amphiphilic polyurethane foam.

Embodiment 3

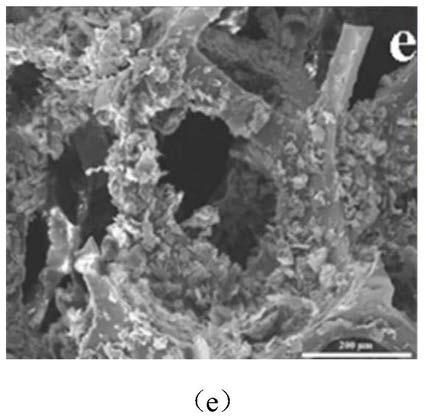

[0041] The process of preparing the super-amphiphilic polyurethane foam material in this example is to pre-coat nano-cellulose and then dip-coat graphene, wherein the nano-cellulose is prepared by chemically hydrolyzing wood powder. The specific process is as follows:

[0042] Put the nanocellulose into a beaker, add deionized water to make it up to volume, and ultrasonically treat it for 30 minutes under the condition of a power of 600W to obtain a uniform nanocellulose aqueous dispersion, wherein the nanocellulose content is 0.7wt%.

[0043] Soak the cleaned and dried polyurethane sponge in the nanocellulose aqueous dispersion for 50 minutes, take it out and fully dry it in an oven at 60°C to obtain a polyurethane sponge coated with nanocellulose. Then soak the polyurethane sponge coated with nanocellulose in the graphene dispersion (1 g graphene / 600 mL water) for 50 min, and then dry it at 60 ° C to obtain a super-amphiphilic polyurethane foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com