Flame-retardant purification device used during biomass gasification and carbonization production

A purification device and biomass technology, applied in gasification process, manufacture of combustible gas, petroleum industry, etc., can solve problems such as equipment accidents, failures, threats to equipment and personal safety, and achieve the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

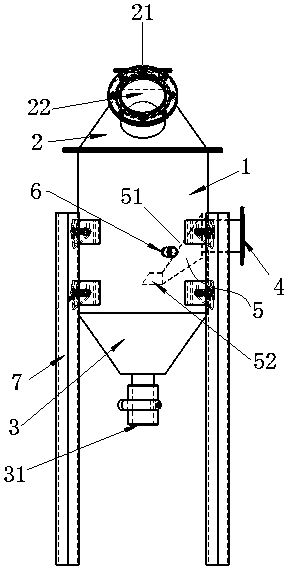

[0013] Such as figure 1 As shown, a flame-retardant purification device for biomass gasification and carbonization production includes a tank body 1 and a gas collecting hood 2 installed on the upper part of the tank body, a liquid container 3 installed on the lower part of the tank body, and a gas collecting hood 2 A gas outlet 21 and aeration blasting port 22 are provided, a liquid discharge port 31 is installed under the liquid container 3, an air inlet 4 is provided on the tank body 1, and a gas-liquid separation structure 5 connected to the air inlet 4 is provided in the tank body , Through the gas-liquid separation structure 5, the tar content is further reduced. A liquid inlet pipe is set on the tank body 1, and liquid is filled into the tank body from the liquid inlet pipe. A limit detonator 6 is installed in the tank body 1 to control the liquid Higher than the outlet of the gas-liquid separation structure 5.

[0014] The gas-liquid separation structure 5 includes a hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com