A method for preparing tungsten silicide coating on the surface of tungsten or tungsten alloy

A tungsten alloy, tungsten silicide technology, applied in the field of high temperature protective coating, can solve the problems that need to be further improved, the thermal expansion coefficient is quite different, etc., achieve good high temperature oxidation resistance, reduce thermal expansion coefficient mismatch, good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A tungsten silicide coating on a tungsten metal surface, the preparation of which comprises the steps of:

[0035] 1) Sandblasting the surface of the W substrate with a sandblasting pressure of 0.4 MPa, sonicating twice in absolute ethanol solution for 5 minutes each time, drying at 100°C for 2 hours, and set aside;

[0036] 2) Use silicon powder with a median particle size of about 30 μm and a purity greater than 98wt.% as the raw material for spraying, dry at 100°C for 3 hours, and set aside;

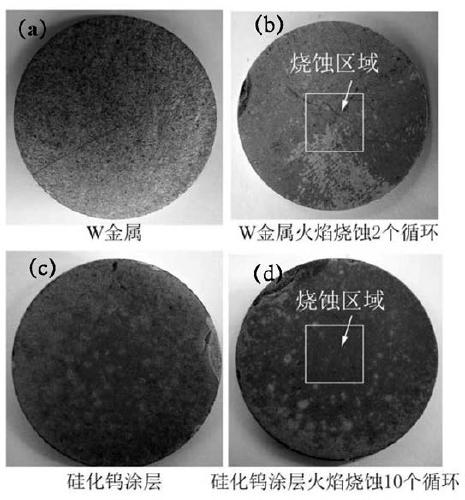

[0037] 3) Using a plasma spraying system (A-2000, Sulzer Metco AG, Switzerland), select the process parameters in Table 1, spray silicon powder onto the surface of the W substrate to form a silicon coating, the thickness of the silicon coating is about 110 μm, figure 1 The XRD results show that the silicon coating is a cubic phase;

[0038] Table 1 is the process parameters of plasma spraying Si coating:

[0039]

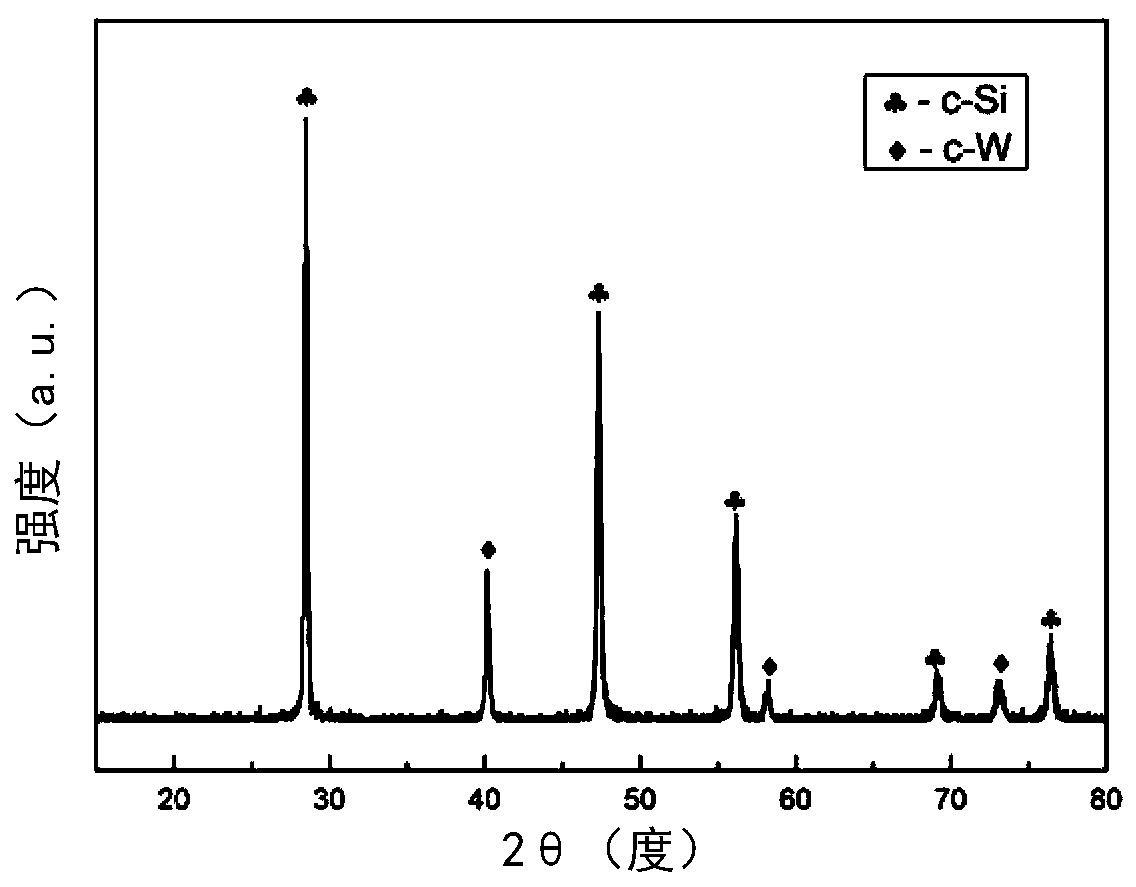

[0040] 4) Using argon-protected vacuum-atmosphere sinterin...

Embodiment 2

[0055] A tungsten silicide coating on a tungsten metal surface, the preparation of which comprises the steps of:

[0056] 1) Sandblasting the surface of the W substrate with a sandblasting pressure of 0.4 MPa, sonicating twice in absolute ethanol solution for 5 minutes each time, drying at 100°C for 2 hours, and set aside;

[0057] 2) Use silicon powder with a median particle size of about 30 μm and a purity greater than 98wt.% as the raw material for spraying, dry at 100°C for 3 hours, and set aside;

[0058] 3) Using plasma spraying technology and selecting the process parameters in Table 3, spray silicon powder onto the surface of the W substrate to form a silicon coating. The thickness of the silicon coating is about 110 μm. figure 1 The XRD results show that the silicon coating is a cubic phase;

[0059] 4) A vacuum-atmosphere sintering furnace protected by argon is used, and a diffusion reaction occurs between the silicon coating and the W substrate to form a tungsten s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com