A modified g-c3n4 quantum dot/tio2 nanowire photoanode and its application

A g-c3n4, nanowire technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve problems such as photocorrosion and environmental pollution, and achieve simple process, excellent stability, excellent stability and photocatalytic hydrogen production performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

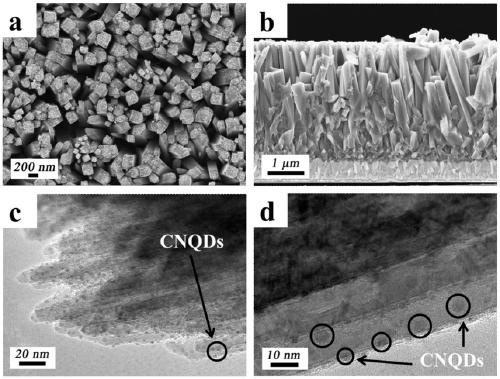

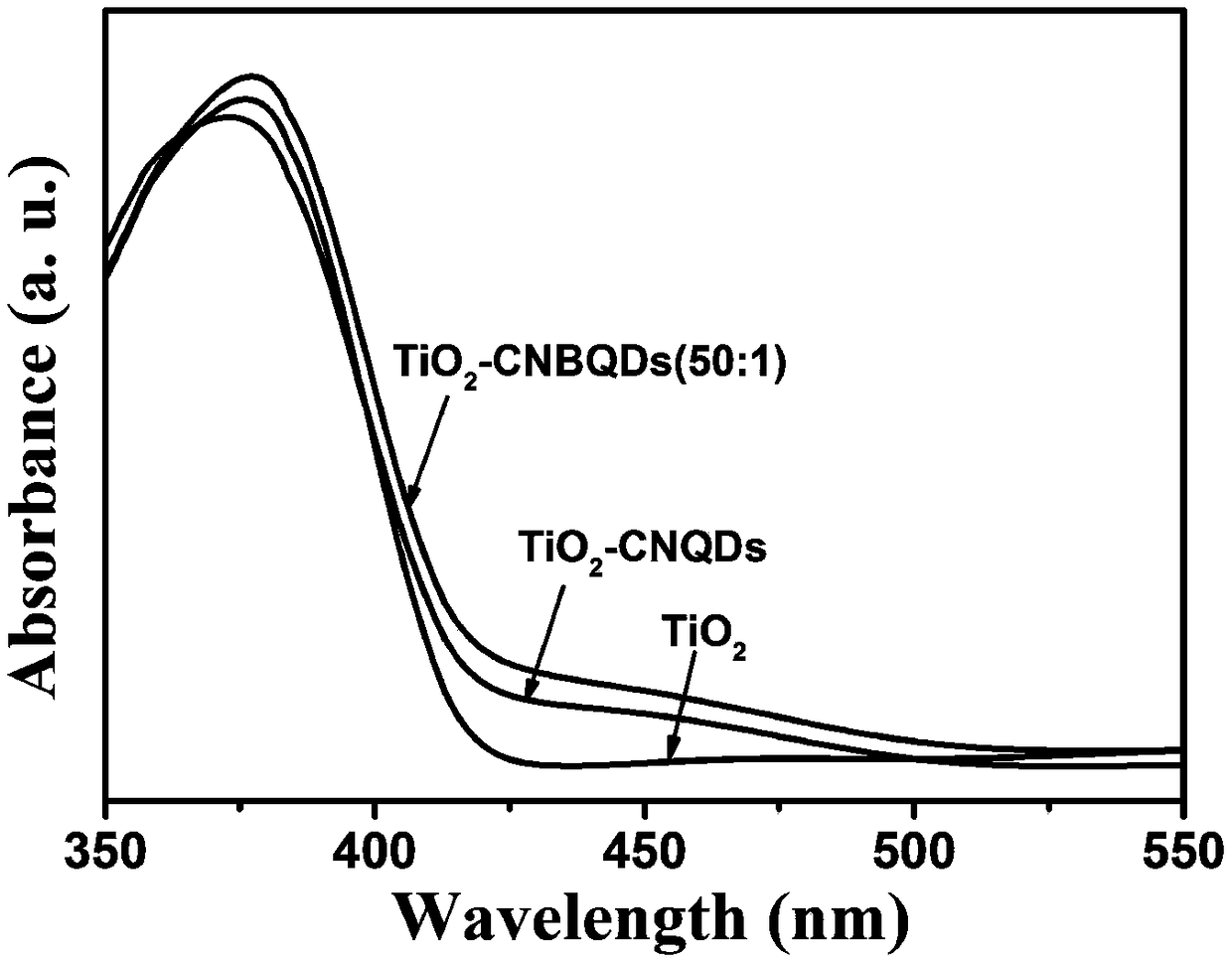

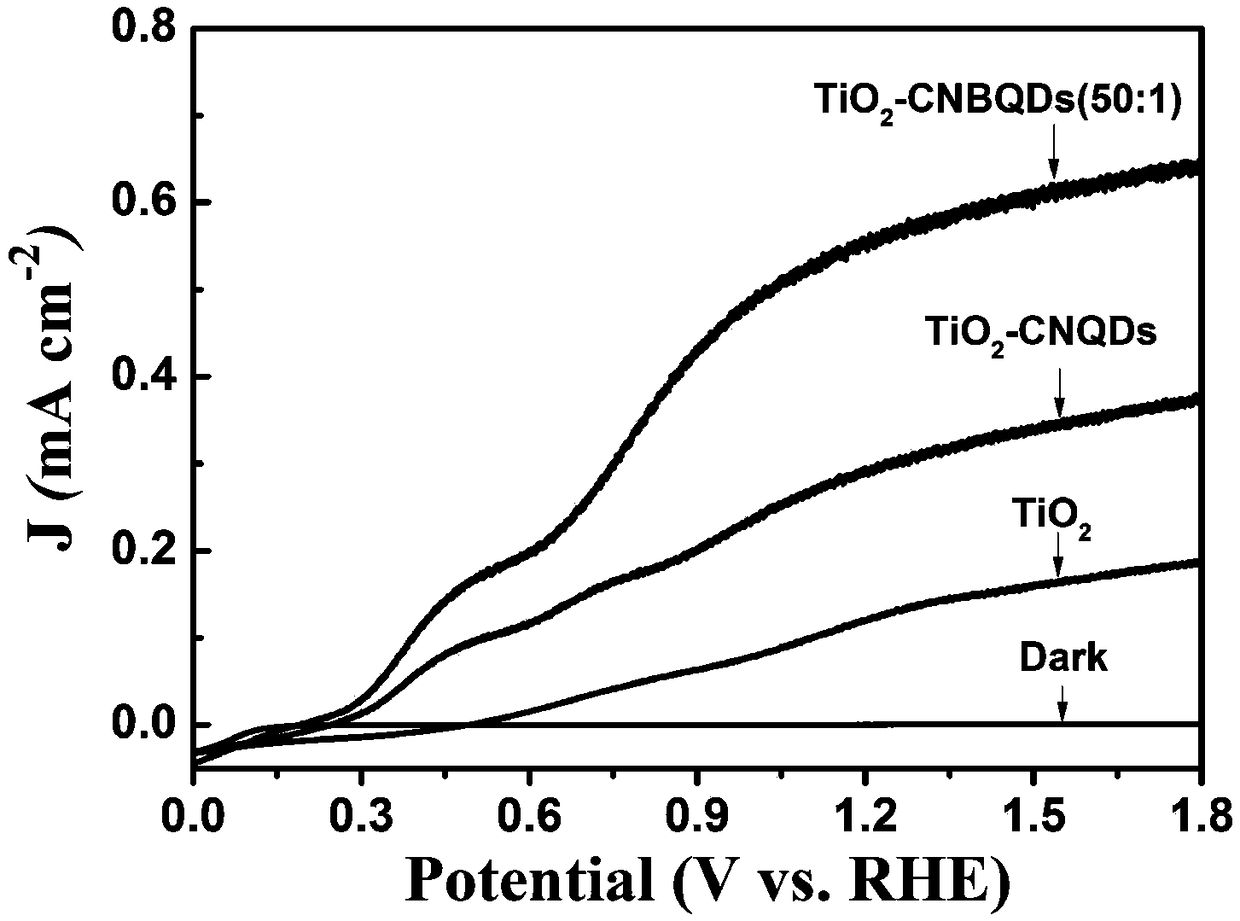

[0031] Example 1 A modified g-C 3 N 4 Quantum dots / TiO 2 Nanowire Photoanodes 1

[0032] A modified g-C 3 N 4 Quantum dots / TiO 2 nanowire photoanodes, the modified g-C 3 N 4 Quantum dots / TiO 2 The preparation method of nanowire photoanode is as follows:

[0033] (1) Place the FTO conductive glass in the growth solution, in which hydrochloric acid, tetrabutyl titanate, and water mixed solution are used as the growth solution, and TiO is synthesized on FTO by solvothermal synthesis at 150°C for 15 hours 2 array of nanowires; the prepared TiO 2 nanowire arrays with N 2 Blow dry for later use;

[0034] (2) Put g-C in the crucible 3 N 4 The precursor dicyandiamide and barbituric acid, the mass ratio of dicyandiamide and barbituric acid is 50:1, mix well, and the TiO obtained in step (1) 2 The nanowires are placed above the precursor in the crucible, and calcined in a muffle furnace by a similar chemical vapor deposition method. The temperature is raised to 550°C at a ...

Embodiment 2

[0035] Example 2 A modified g-C 3 N 4 Quantum dots / TiO 2 Nanowire Photoanodes 2

[0036] A modified g-C 3 N 4 Quantum dots / TiO 2 nanowire photoanodes, the modified g-C 3 N 4 Quantum dots / TiO 2 The preparation method of nanowire photoanode is as follows:

[0037] (1) Place the FTO conductive glass in the growth solution, in which hydrochloric acid, tetrabutyl titanate, and water mixed solution are used as the growth solution, and TiO is synthesized on FTO by solvothermal synthesis at 150°C for 18 hours 2 array of nanowires; the prepared TiO 2 nanowire arrays with N 2 Blow dry for later use;

[0038] (2) Put g-C in the crucible 3 N 4 The precursor urea and barbituric acid, the mass ratio of urea and barbituric acid is 100:1, mix evenly, the TiO obtained in step (1) 2 The nanowires are placed above the precursor in the crucible, and calcined in a muffle furnace by a similar chemical vapor deposition method. The temperature is raised to 550°C at a heating rate of 2.5...

Embodiment 3

[0039] Example 3 A modified g-C 3 N 4 Quantum dots / TiO 2 Nanowire Photoanodes 3

[0040] The modified g-C provided by this embodiment 3 N 4 Quantum dots / TiO 2 The preparation method of the nanowire photoanode is the same as in Example 1, except that the mass ratio of dicyandiamide to barbituric acid in this example is 10:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com