Method for preparing fabric antibacterial finishing liquid

An antibacterial finishing liquid and fabric technology, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of washing and floating, hard hand feeling, skin allergy, etc., to achieve a simple preparation process and improve antibacterial performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

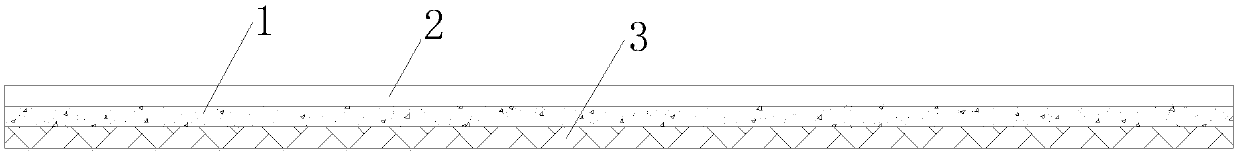

Image

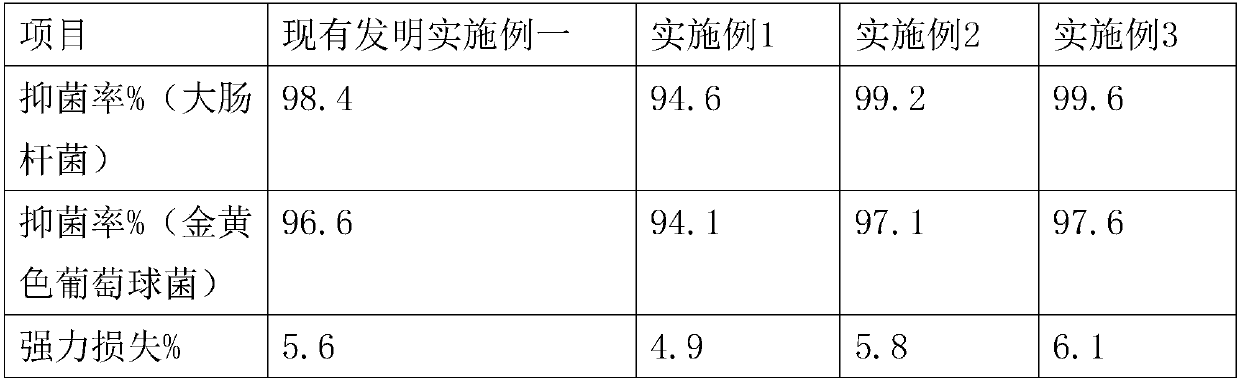

Examples

Embodiment 1

[0018] A preparation method for fabric antibacterial finishing solution, comprising the following steps:

[0019] (1) Weigh Houttuynia cordata, astragaloside, isatidis, myristic acid, allicin, sweet potato starch, malt oil, ethanol, potassium sorbate, lignin, pomegranate peel, Prunella vulgaris, wormwood, and Akebia Stir the rest of the raw materials except ethanol evenly to obtain processed powder;

[0020] (2) Put the above-mentioned processed powder in a closed container, pass in water vapor, keep the temperature at 180°C, the pressure at 0.2MPa, keep the temperature and hold the pressure for 2 hours, then take out the processed powder and dry it at a high temperature of 260°C, and the obtained processed powder The moisture content of the material is 4%;

[0021] (3) Add the above-mentioned processed powder into ethanol and mix uniformly to obtain an antibacterial liquid.

[0022] The antibacterial finishing solution is made of the following raw materials in parts by weig...

Embodiment 2

[0024] A preparation method for fabric antibacterial finishing solution, comprising the following steps:

[0025] (1) Weigh Houttuynia cordata, astragaloside, isatidis, myristic acid, allicin, sweet potato starch, malt oil, ethanol, potassium sorbate, lignin, pomegranate peel, Prunella vulgaris, wormwood, and Akebia Stir the rest of the raw materials except ethanol evenly to obtain processed powder;

[0026] (2) Put the above-mentioned processed powder in a closed container, pass in water vapor, keep the temperature at 180°C, the pressure at 0.2MPa, keep the temperature and hold the pressure for 2 hours, then take out the processed powder and dry it at a high temperature of 260°C, and the obtained processed powder The moisture content of the material is 4%;

[0027] (3) Add the above-mentioned processed powder into ethanol and mix uniformly to obtain an antibacterial liquid.

[0028] The antibacterial finishing solution is made of the following raw materials in parts by weig...

Embodiment 3

[0035] An antibacterial finishing solution for flame-retardant fabrics, the antibacterial finishing solution is made of the following raw materials in parts by weight: 1.5 parts of Houttuynia cordata, 0.3 parts of astragaloside, 6 parts of isatidis, 4 parts of myristic acid, 1 part of allicin, and 1 part of sweet potato 3 parts of starch, 5.5 parts of malt oil, 150 parts of ethanol, 2 parts of potassium sorbate, 2 parts of lignin, 6.5 parts of pomegranate peel, 5.6 parts of Prunella vulgaris, 0.6 parts of wormwood, 8 parts of Chuanmutong, 2.6 parts of Guangxi Guoluhuang , Morinda officinalis 2.2 parts, Guangxi Guoluhuang 2.6 parts, Morinda officinalis 2.2 parts.

[0036] A preparation method for fabric antibacterial finishing solution, comprising the following steps:

[0037] (1) Weigh Houttuynia cordata, astragaloside, isatidis, myristic acid, allicin, sweet potato starch, malt oil, ethanol, potassium sorbate, lignin, pomegranate peel, Prunella vulgaris, wormwood, and Akebia ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com