Eddy Current Probe Single Axis Pusher

A technology of eddy current probes and pushers, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of affecting transmission efficiency and detection effect, troublesome operation, easy to wear probes, etc., to ensure synchronization and timeliness, and not easy Effects of damage, ease of maintenance and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

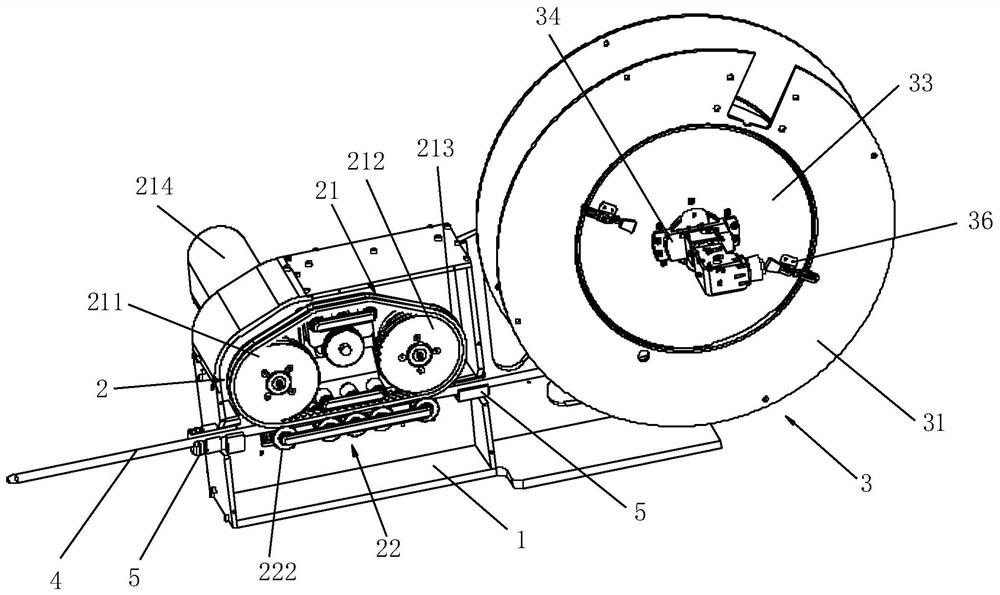

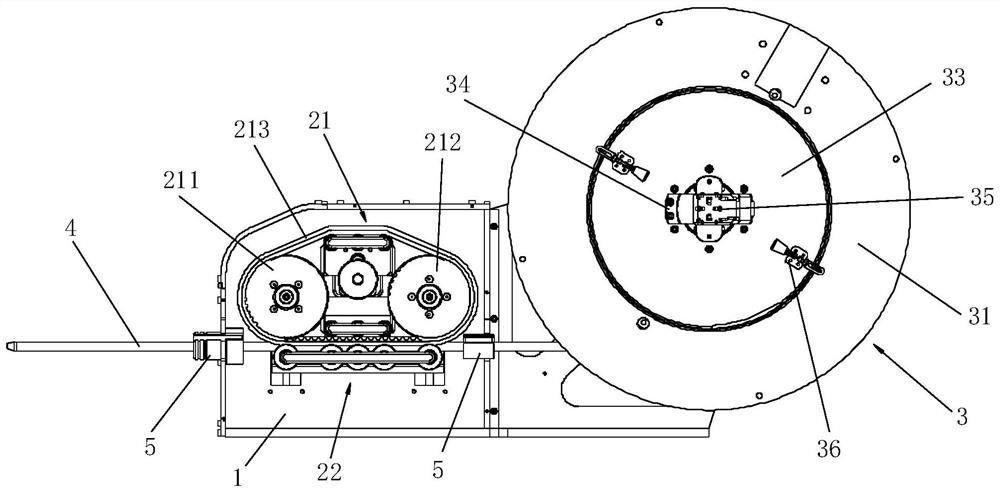

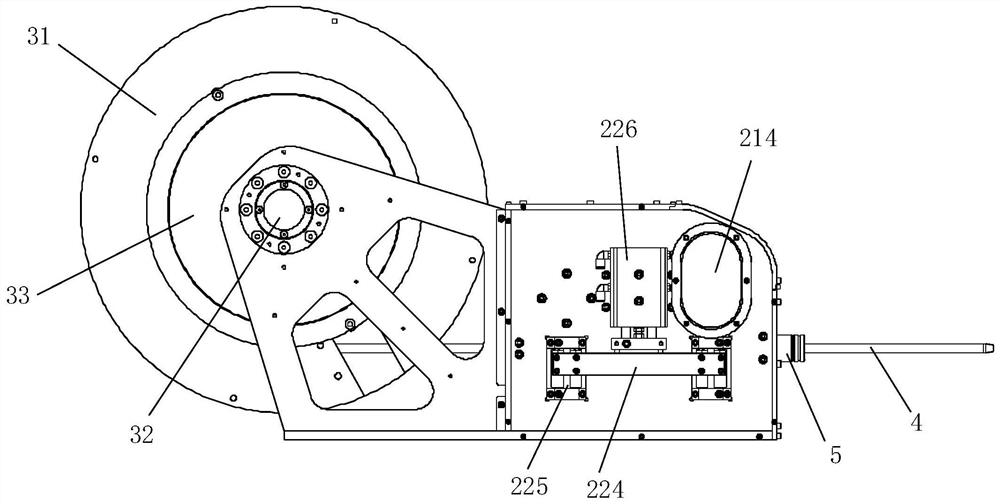

[0030] like Figure 1 to Figure 3 As shown, an eddy current probe single-axis pusher is suitable for a coilable cable-like probe 4, the pusher includes a mounting frame 1, and is arranged on the mounting frame 1 for winding and releasing the winding of the probe 4. The device 3, the probe 4 has a release section protruding from the winding device 3, the pusher also includes a delivery device 2 arranged on the mounting frame 1 for clamping the release section, the delivery device 2 includes a delivery device arranged on the installation frame 1 The belt pulley assembly 21 and the C-shaped pressing wheel assembly 22 that can move up and down on the mounting frame 1 and opposite to the belt pulley assembly 21, there is a gap between the belt pulley assembly 21 and the C-shaped pressing wheel assembly 22 to accommodate the probe 4 And a transmission channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com