Film formation blocking agent for shale gas formation drilling fluid and preparation method thereof

A film-forming plugging agent and drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of large micro-fractures, failure to block, and the inability to effectively seal micro-sized pores and fractures. Blocking and other problems to achieve the effect of preventing infiltration, preventing the collapse of the well wall, and maintaining the stability of the well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

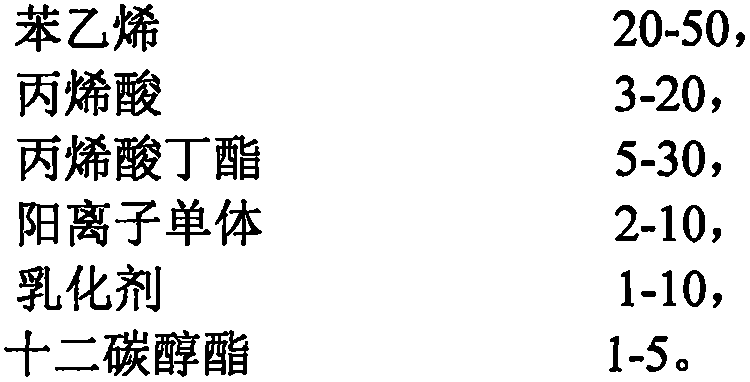

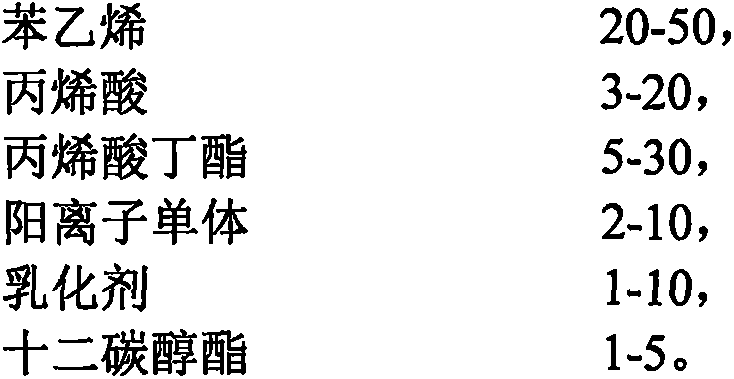

[0023] Add 0.5 parts of OP-10 and 0.3 parts of sodium lauryl sulfate into 30 parts of deionized water, heat to 42°C, under the protection of nitrogen, slowly add a mixture of 20 parts of styrene, 5 parts of acrylic acid and 30 parts of butyl acrylate solution, stir well, slowly add 0.05 parts of ammonium persulfate, heat up to 81°C, react for 3 hours, add 2 parts of dimethyl diallyl ammonium chloride, add 2 parts of dodecyl alcohol ester, continue to react for 2 hours , adding 8 parts of ammonia water to adjust the pH of the emulsion to 7-8 to obtain a bluish white emulsion, and the obtained emulsion is the film-forming plugging agent for the shale gas formation drilling fluid.

Embodiment 2

[0025] Add 1 part of sodium alkylphenol ether sulfosuccinate to 30 parts of deionized water, heat to 40°C, and slowly add a mixture of 20 parts of styrene, 5 parts of acrylic acid and 10 parts of butyl acrylate under nitrogen protection , stir well, slowly add 0.05 parts of potassium persulfate, heat up to 78 ° C, react for 4 hours, add 2 parts of dimethyl diallyl ammonium chloride, add 2 parts of dodecyl alcohol ester, add azoisobutyl 0.05 parts of nitrile, continue to react for 4 hours, add 8 parts of ammonia water to adjust the pH of the emulsion to 7-8, and obtain a bluish white emulsion, and the obtained emulsion is the film-forming plugging agent for the shale gas formation drilling fluid.

Embodiment 3

[0027] Add 1 part of sodium alkylphenol ether sulfosuccinate to 30 parts of deionized water, heat to 40°C, and slowly add a mixture of 30 parts of styrene, 5 parts of acrylic acid and 30 parts of butyl acrylate under nitrogen protection , stir well, slowly add 0.05 parts of potassium persulfate, heat up to 78 ° C, react for 4 hours, add 3 parts of dimethyl diallyl ammonium chloride, add 2 parts of dodecyl alcohol ester, continue to react for 4 hours, Add 8 parts of ammonia water to adjust the pH of the emulsion to 7-8 to obtain a bluish white emulsion, and the obtained emulsion is the film-forming plugging agent for the shale gas formation drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com