Pharmaceutical Processing Systems

A processing system and edge trimming technology, used in manufacturing tools, metal processing equipment, machine tools suitable for grinding workpiece edges, etc. High problems, to avoid re-moisture, low equipment failure rate, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

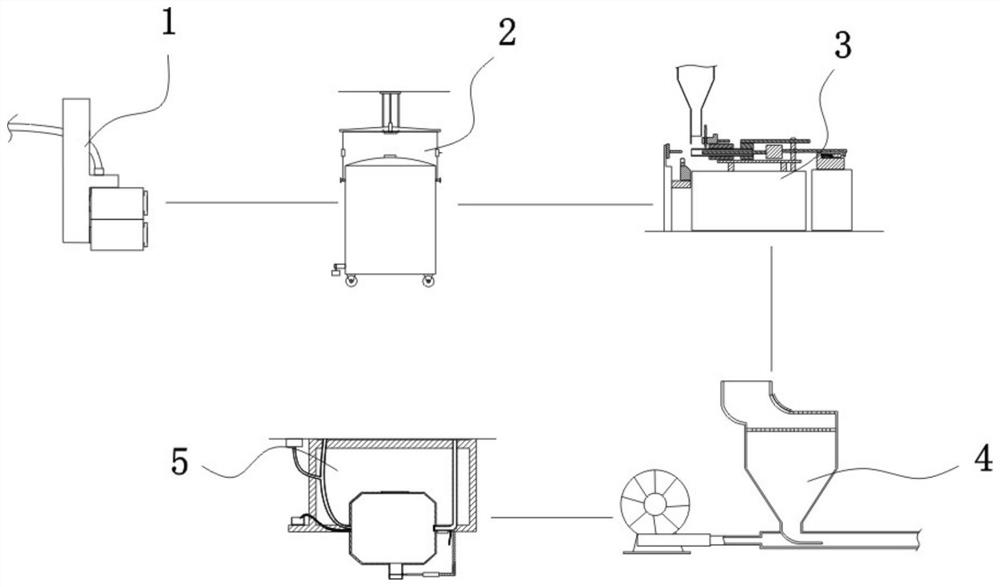

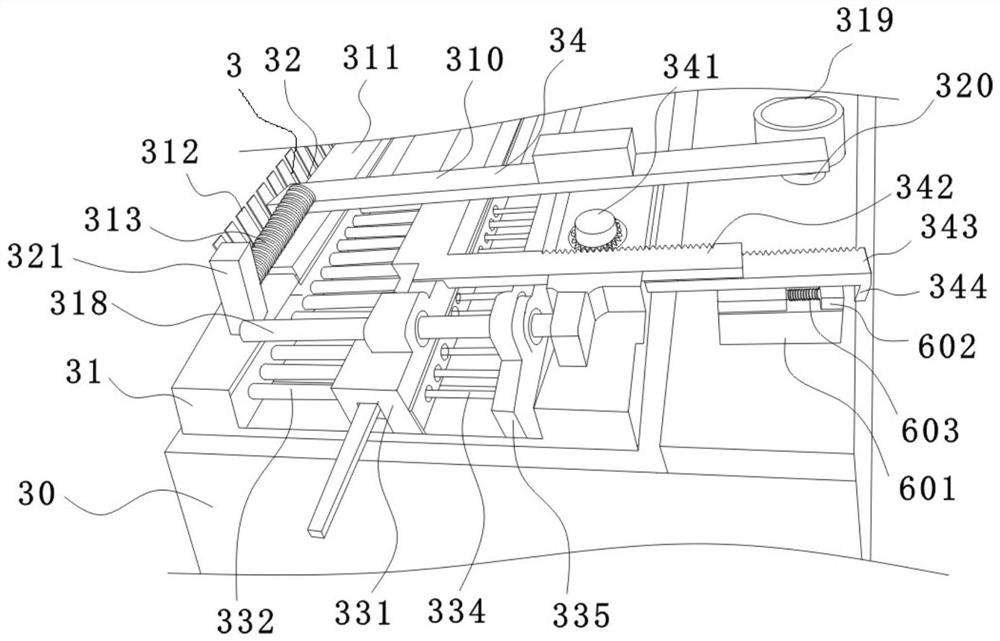

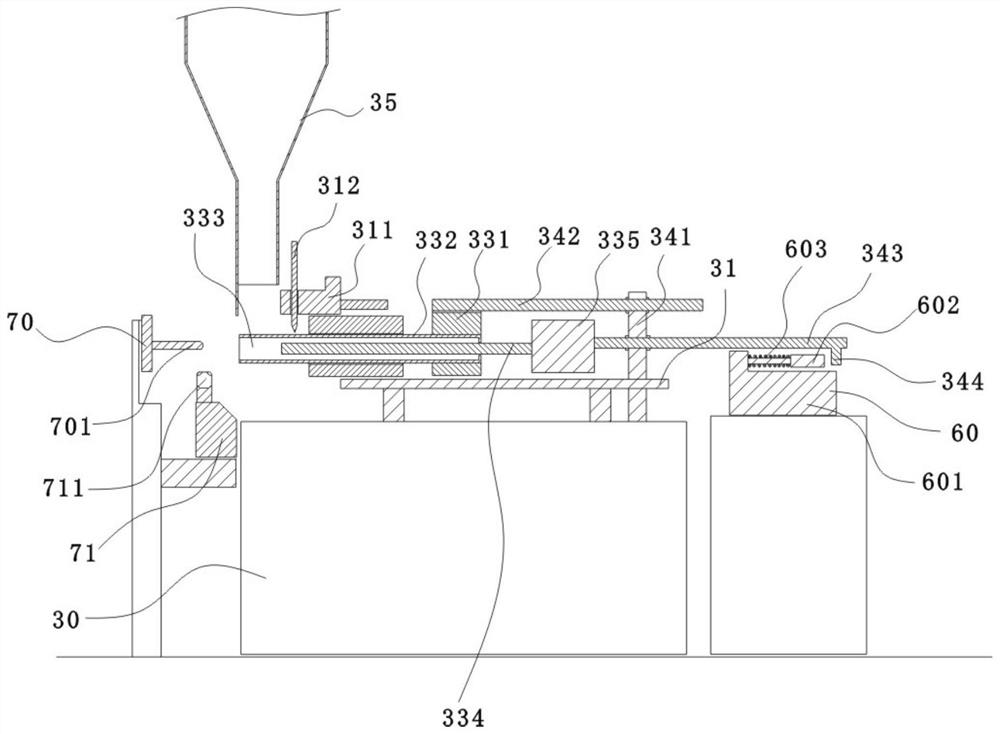

[0033] Such as Figure 1-3 As shown, a pharmaceutical processing system includes an oiling device 1, a weighing device 2, a trimming device 3, a feeding device 4 and a polishing device 5; wherein the trimming device 3 includes a base 30 located on the ground, an operating Table 31, trimming part 32, fixing part and drive part 34; Concretely, described operating table 31 is arranged on the seat body 30, and this operating table 31 is a metal frame, and operating table 31 and is located at seat body 30 inside The cylinder is fixed, the cylinder is activated, and the console 31 can move up and down on the base 30; A rod 311 and a plurality of trimming members 312, a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com