A controllable cooling device for electric welding machine

A cooling device, controllable technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of temperature rise, unfavorable carrying, waste of welding machine power, etc., to improve the cooling speed and cooling speed Controllable, effect of increasing cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

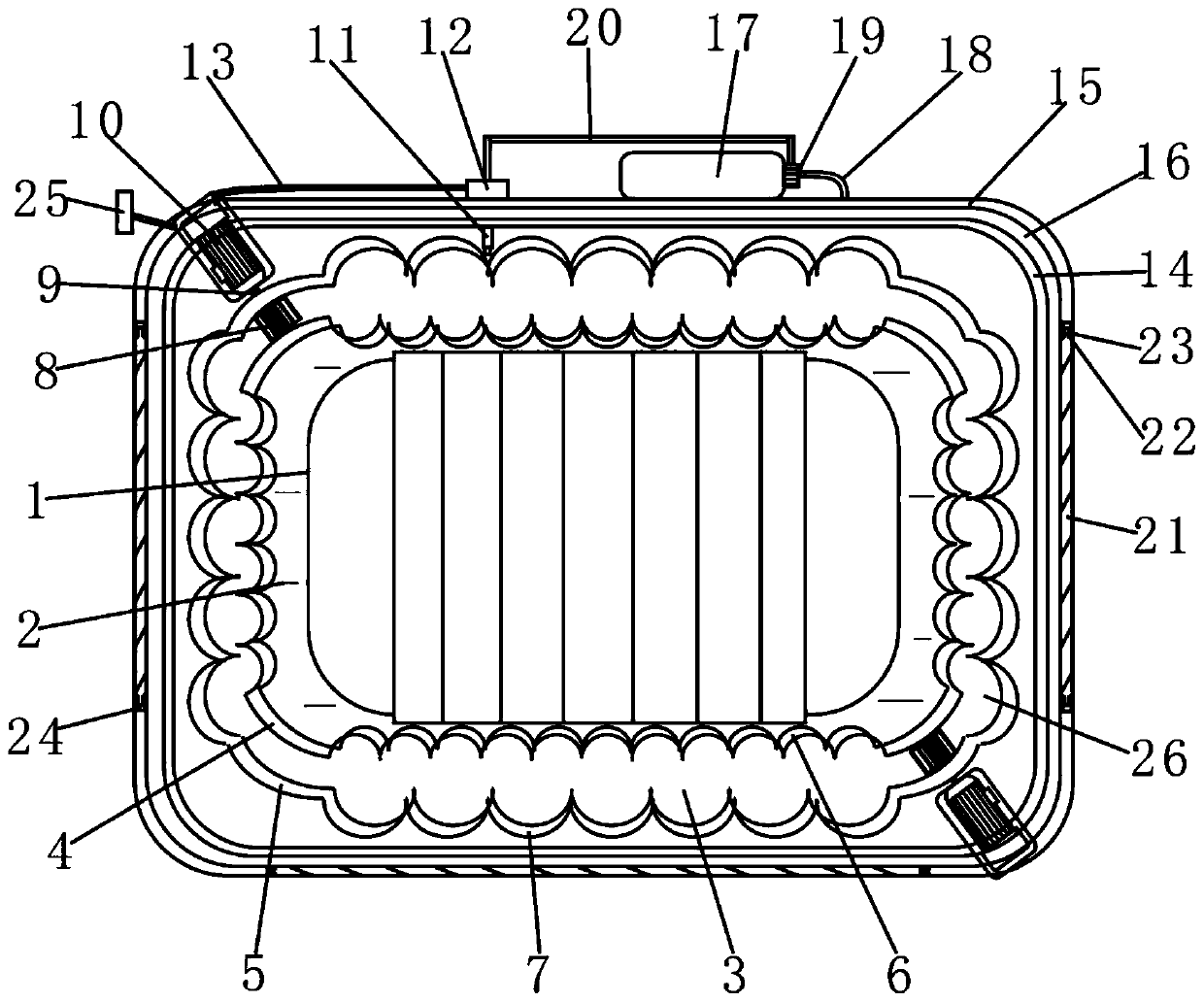

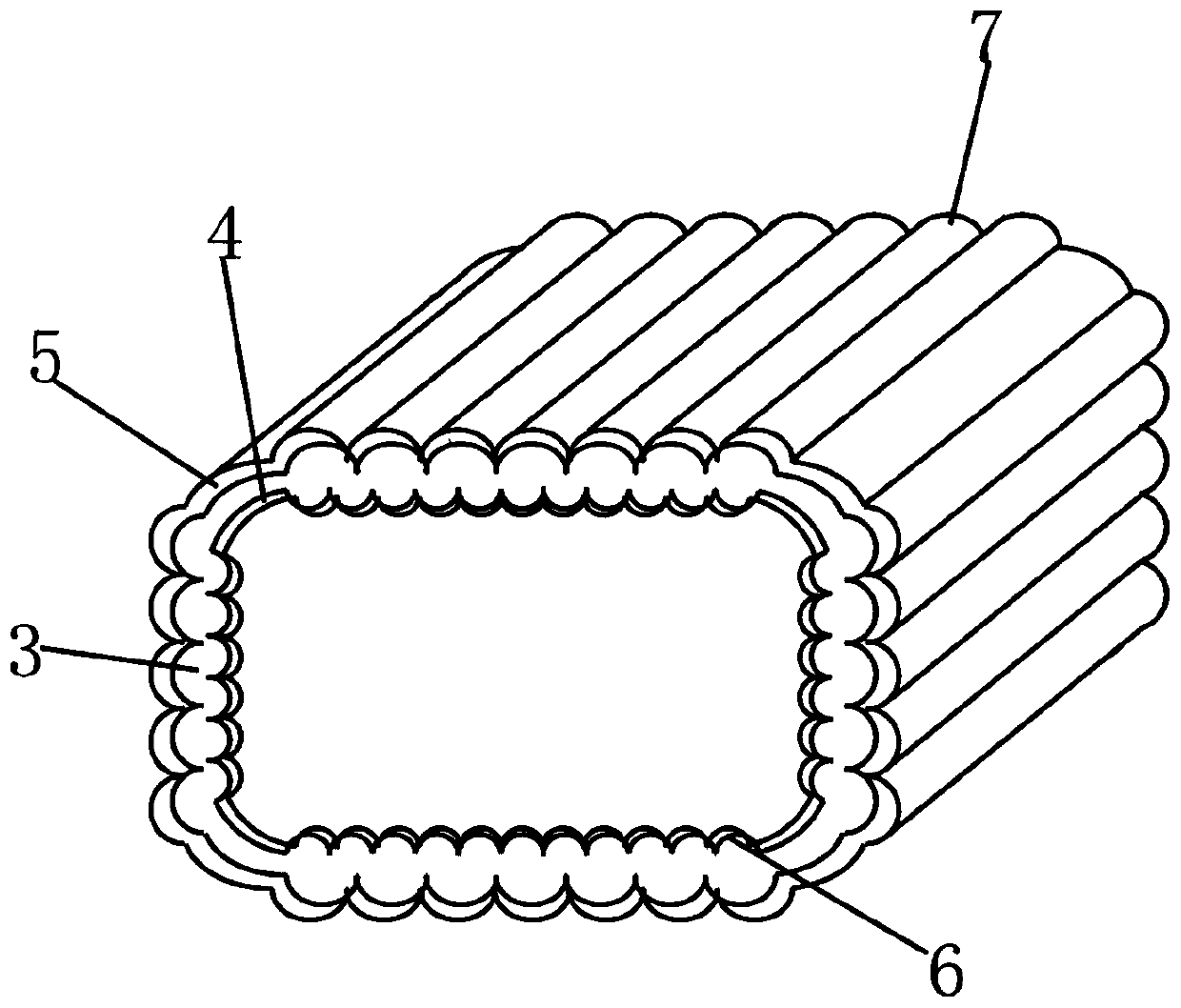

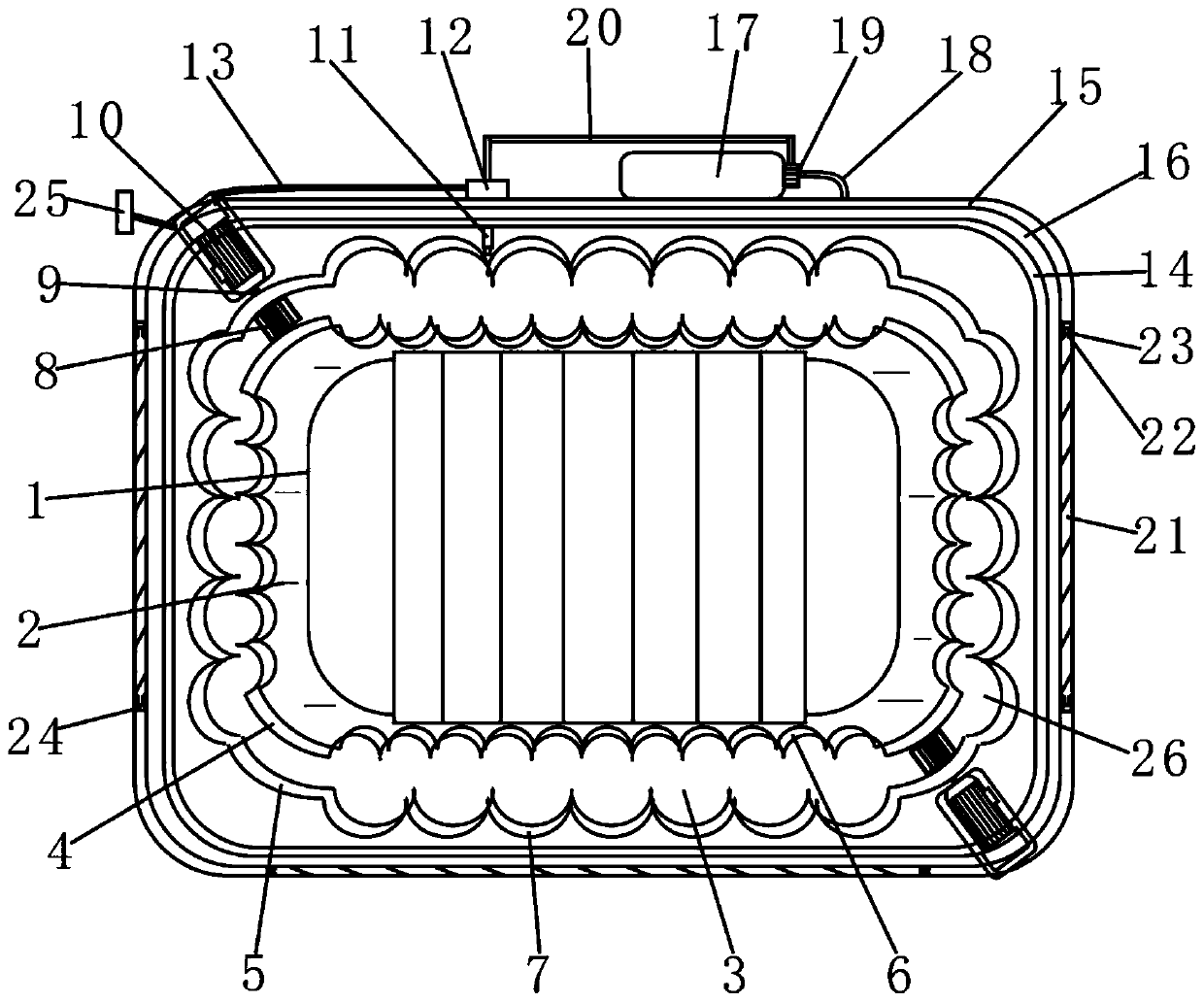

[0024] Such as figure 1 with figure 2 As shown, the present invention provides a controllable cooling device for an electric welding machine, including a transformer 1, an oil immersion liquid 2 is arranged around the outer surface of the transformer 1, and a circulating cooling chamber 3 is arranged outside the oil immersion liquid 2 , the circulating cooling chamber 3 includes an inner wall 4 and an outer wall 5, the circulating cooling chamber 3 is provided with an oil-based coolant 26, the inner wall 4 is provided with a small protrusion 6, and the outer surface of the outer wall 5 is provided with a large Protrusions 7, the cross-sections of the small protrusions 6 and the large protrusions 7 are semicircular, and the number of small protrusions 6 is not less than 10, and the number of large protrusions 7 is not less than 6. To increase the heat dissipation area, thereby speeding up the cooling rate.

[0025] Such as figure 1 with figure 2 As shown, the circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com