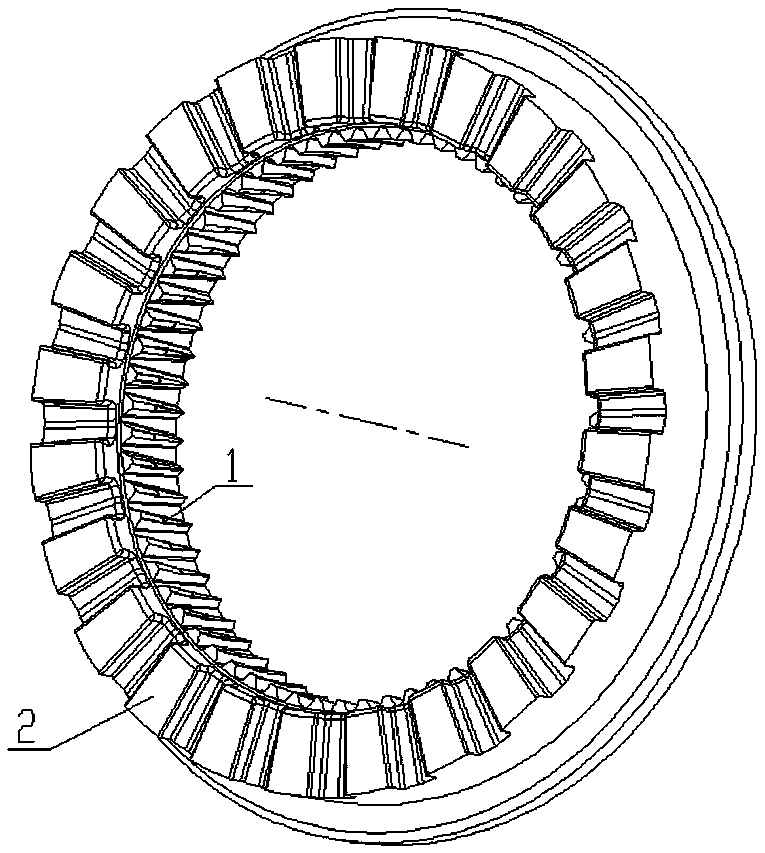

Cold precision forging forming technology for inner spline lock ring with inverted cone

A forming process and internal spline technology, which is applied in the field of cold precision forging forming process and metal plastic forming process, can solve the problems of poor wear resistance and poor tissue density of the lock ring, and achieve the guarantee of processing accuracy, positional accuracy and process The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further illustrated below by way of examples.

[0038] The present invention is a cold precision forging process of an internal spline lock ring with an inverted cone. The main body of the process is to simultaneously complete the end face ratchet and internal spline precision forging through the cold block forming process. The specific process is as follows:

[0039] (1) First prepare the material

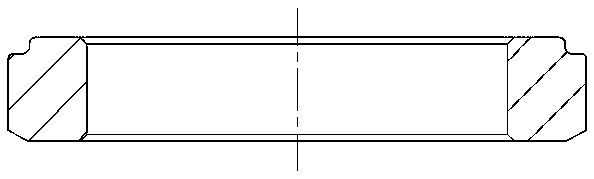

[0040] Cut solid bars as required. This embodiment is a lock ring in a car gearbox. The maximum outer diameter of the finished product is 92mm, and the diameter of the selected solid bar is 45mm, and the difference between the two is 47mm;

[0041] (2) Ring rolling billet

[0042] The ring blank is obtained by rolling, which is realized through the following steps:

[0043] (2.1) Cold heading the billet,

[0044] (2.2) forged blind hole,

[0045] (2.3) Chong Lianpi,

[0046] (2.4) rolling into a ring;

[0047] (3) The inner diameter of the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com