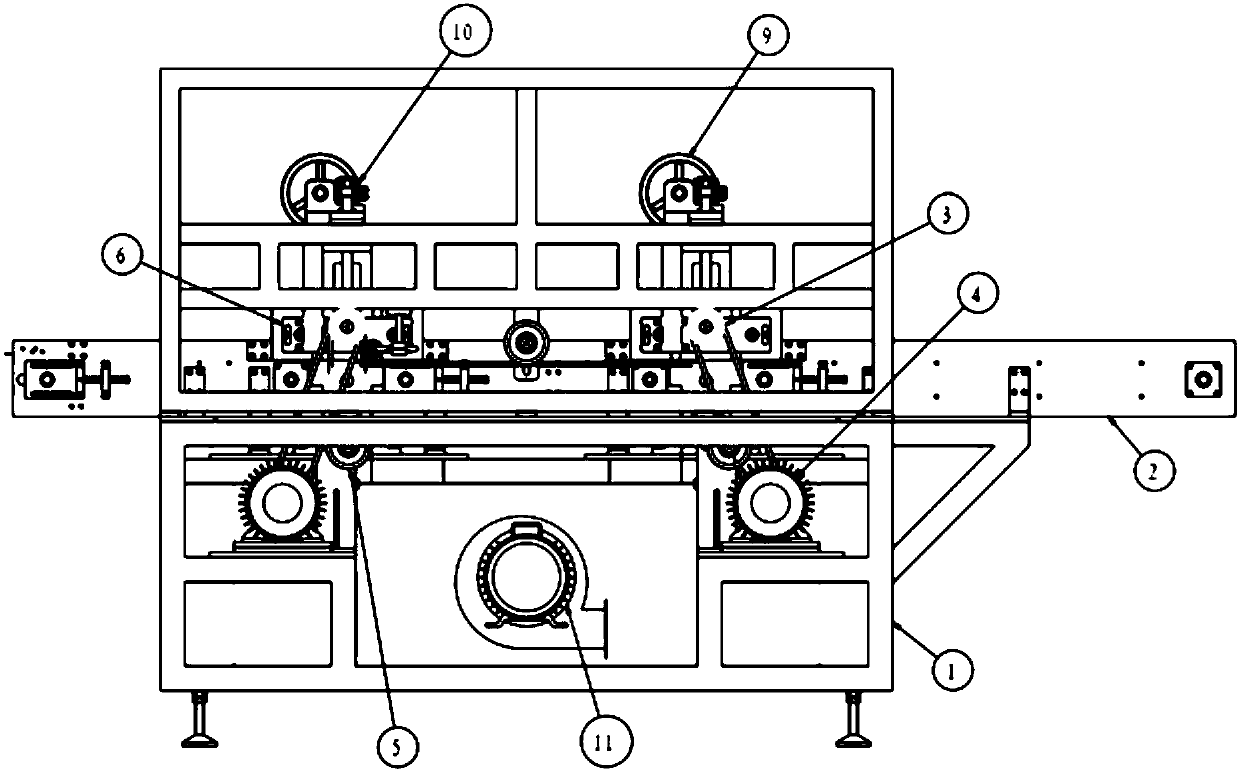

Full-automatic two-sided deburring machine

A deburring machine, fully automatic technology, applied in the direction of grinding frame, grinding feed movement, grinding drive device, etc., can solve the problem of high labor intensity of operators, lack of safety guarantee, troublesome and laborious deburring, etc. Problems, to achieve the effect of convenient control, light weight, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below.

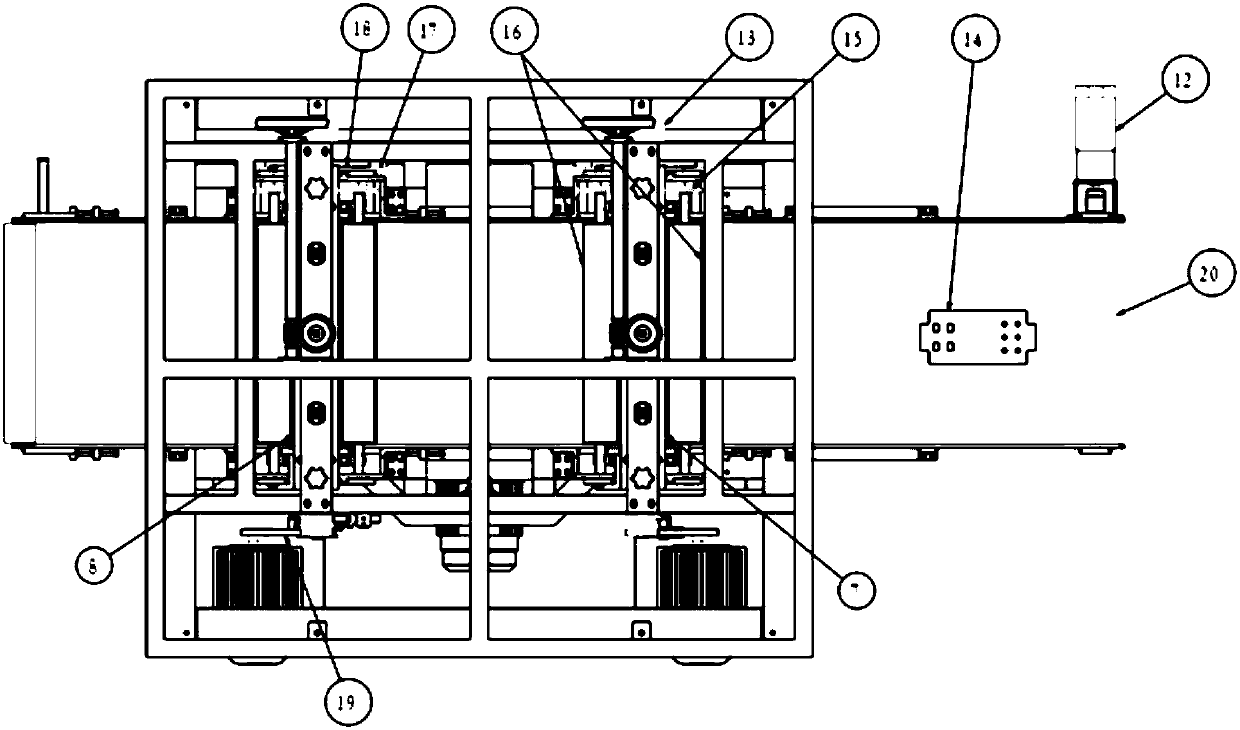

[0028] A fully automatic double-sided deburring machine includes a frame, a feeding mechanism, a forward roller brush device, a reverse roller brush device, a pressing device, a rough adjustment device, a fine adjustment device, a dust removal system, and a controller.

[0029] The feeding mechanism includes: three sections of conveyor belts, two supporting parts, a first motor, and a chain transmission mechanism. Along the conveying direction of the sheet metal plate, the first conveyor belt, the first support, the second conveyor belt, the second support, and the third conveyor belt are sequentially set on the frame, and are located on the two sides of the feeding mechanism. Between the side plates; the chain transmission mechanism connects the three conveyor belts in series, the first motor drives the three conveyor belts to rotate synchronously, and the first motor is installed on the side plate of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com