Carbon fiber plate anti-deformation baking support

A carbon fiber board, anti-deformation technology, used in other household appliances, household appliances, flat products, etc., can solve the problems of low yield, high toughness and strength, and achieve the effect of improving yield and preventing forced re-deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

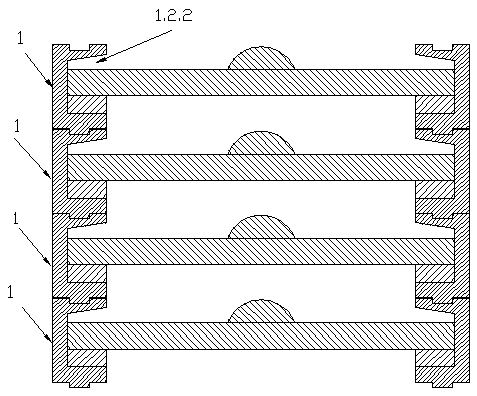

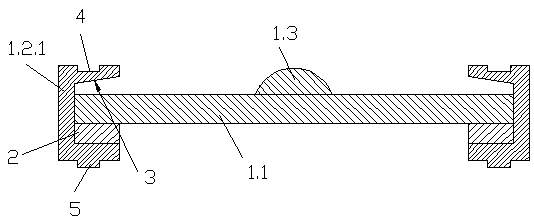

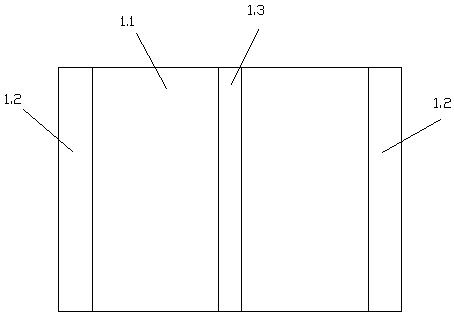

[0014] Embodiment 1: A carbon fiber plate anti-deformation baking bracket, including several clamping plates 1 superimposed on each other, the clamping plate 1 includes a glass substrate 1.1, a strip frame 1.2 and a center of the upper surface of the glass substrate 1.1 The convex strip 1.3, the strip-shaped frame 1.2 includes a U-shaped base 1.2.1, the U-shaped groove 1.2.2 of the U-shaped base 1.2.1 of the two-shaped frame 1.2 is arranged oppositely, and the side of the glass substrate 1.1 is inserted in the U-shaped In the U-shaped groove 1.2.2 of the base body 1.2.1, a strip spacer 2 is lined between the bottom surface of the glass substrate 1.1 and the lower side arm of the U-shaped groove 1.2.2, so that the upper surface of the glass substrate 1.1 and the U-shaped groove 1.2 .2 A slot 1.2.3 is formed between the upper arms to hold the carbon fiber plate, the height of the slot 1.2.3 is slightly smaller than the thickness of the carbon fiber plate, and the upper arm of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap