Horizontal frequency adjusting mass damper

A technology of frequency modulation mass damping and leveling, which is applied in the direction of building components, shockproof, building types, etc., can solve the problems of difficult installation, cumbersome processing of viscous dampers, and large friction, and achieves convenient processing, small friction, and reduced friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

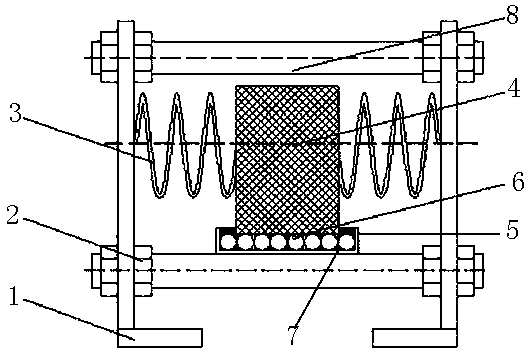

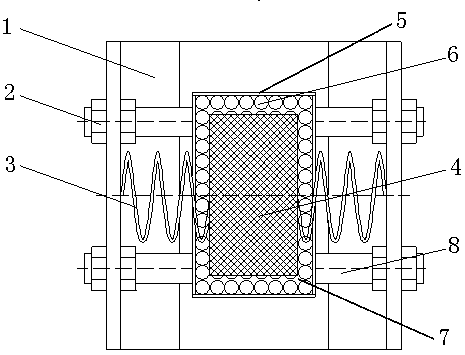

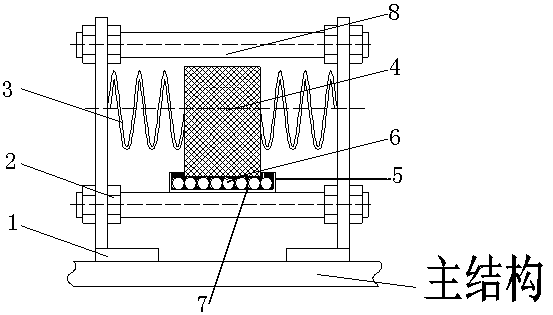

[0017] Such as figure 1 with figure 2 As shown, the horizontal frequency modulation mass damper includes wall seat 1, lock nut 2, spring 3, mass block 4, damping liquid tank 5, steel ball 6, damping liquid 7, and screw rod 8. If the outermost side is wall seat 1 The two wall bases 1 are connected by screw rods 8, and the joints are tightened with lock nuts 2. The damping fluid tank 5 is welded on the two screw rods 8 at the bottom of the wall base 1, and the screw rod 8 at the upper part of the wall base 1 plays a connecting role. The steel ball 6 is covered with the damping liquid tank 5, the damping liquid 7 is filled with the damping liquid tank 5, the mass block 4 is placed on the steel ball 6, and is located in the center of the two wall seats 1, and the spring 3 is connected Mass block 4 and two wall seats 1.

[0018] Working principle of the present invention is:

[0019] In the present invention, the steel ball 6 is arranged in the damping liquid tank 5 to realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com