Dehumidifying fan of drying machine

A technology of dryer and fan, applied in the field of machinery, can solve the problems of impeller collision, need of space, fan damage, etc., and achieve the effect of avoiding strong collision and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

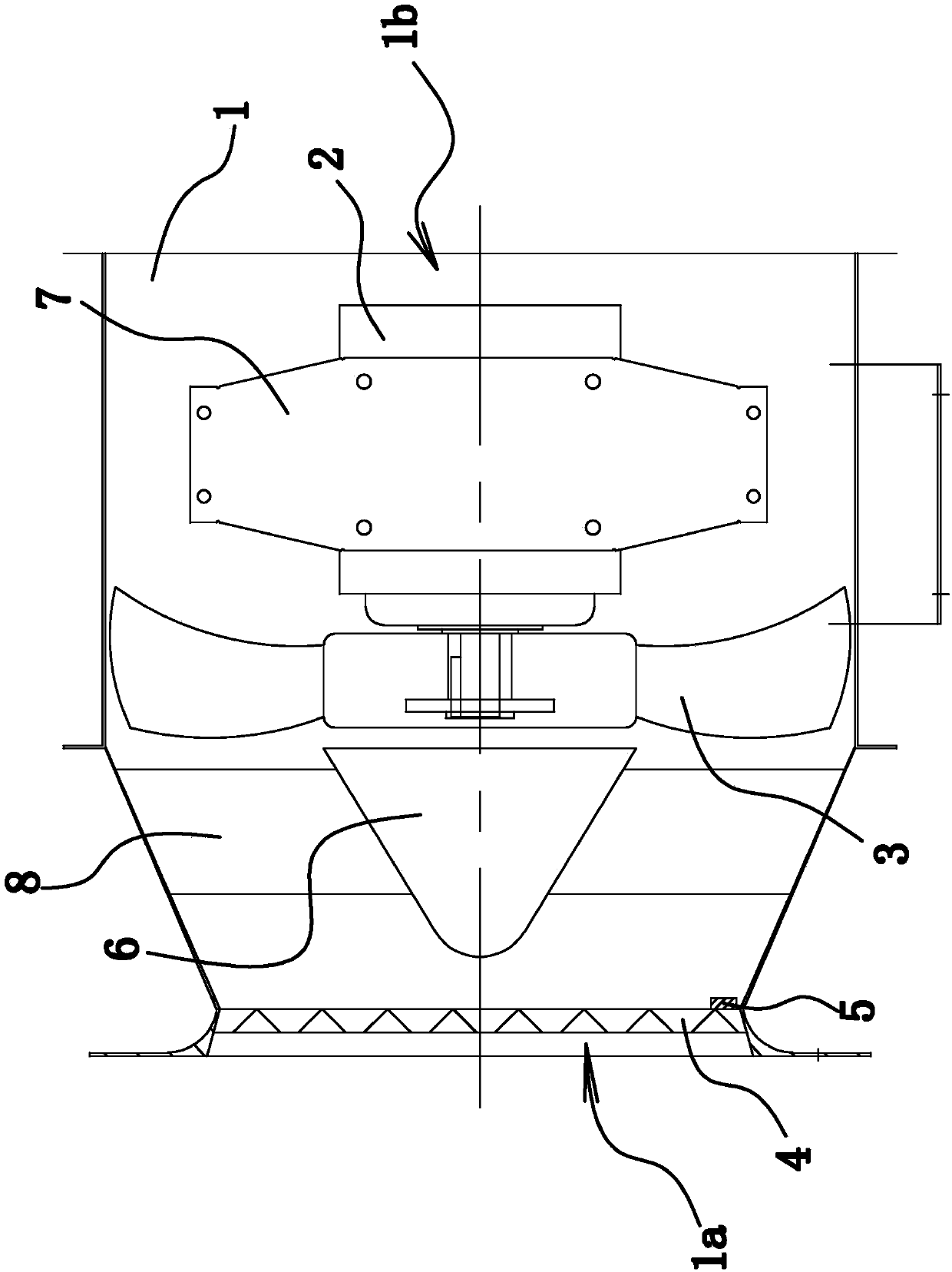

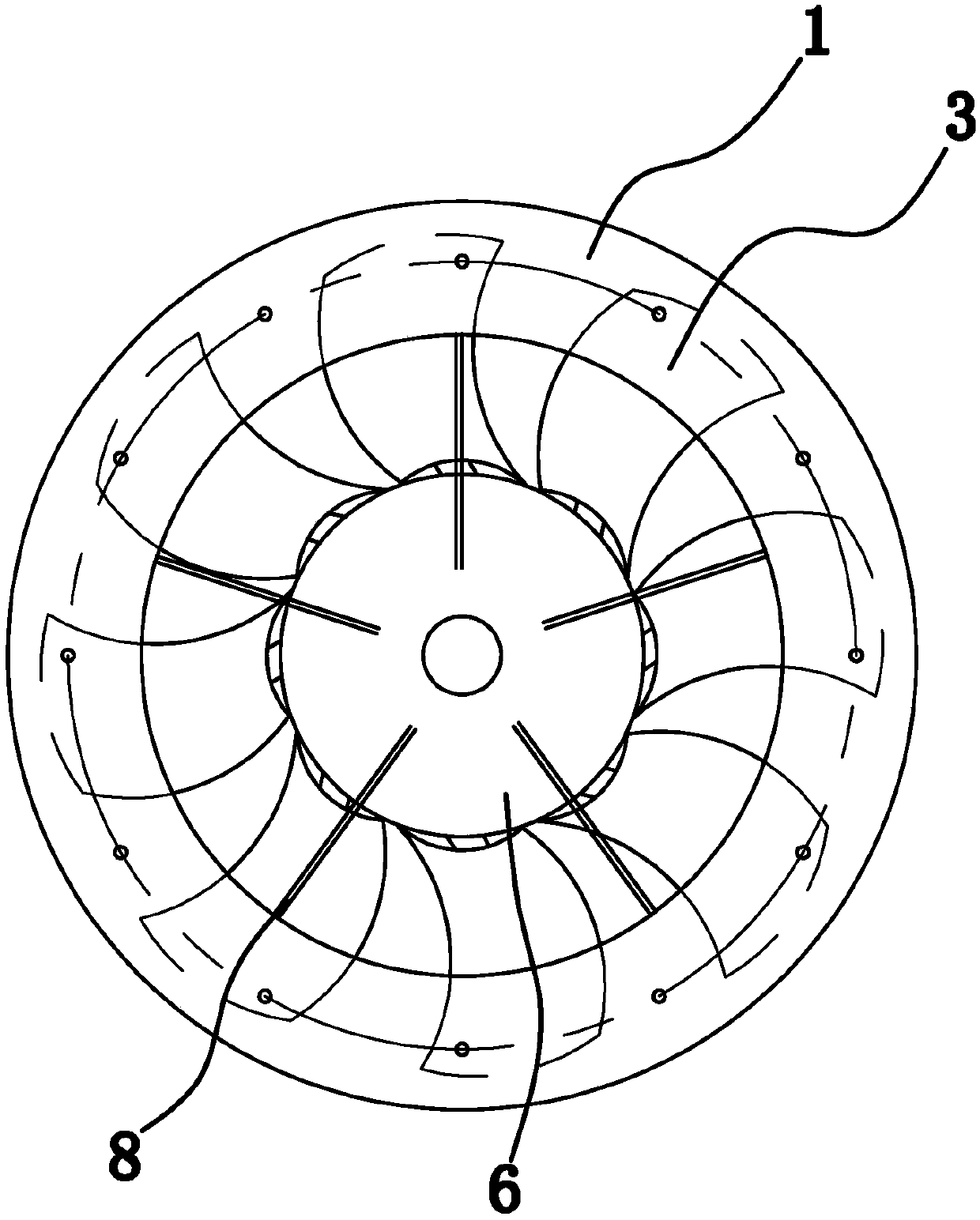

[0012] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

[0013] Such as figure 1 with figure 2 As shown, the dehumidification blower of the dryer is composed of a barrel 1, a motor 2, an impeller 3, a filter screen 4, a magnetic block 5, and a diversion cap 6. Wherein, the filter screen 4 is made of magnetic material, and the magnetic material can be iron or an alloy containing iron.

[0014] Specifically, the barrel 1 is cylindrical, and its two ends are respectively an air inlet 1a and an air outlet 1b. Both the motor 2 and the impeller 3 are located in the machine barrel 1, wherein the motor 2 is fixedly connected to the machine barrel 1 through the support 7, the impeller 3 is located between the motor 2 and the air inlet 1a, and the impeller 3 is connected to the main shaft of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com