Cold and hot alternating test device and method for converter valve cooling system

A technology of alternating cold and heat and cooling system, which is used in measuring devices, testing of mechanical components, control/regulation systems, etc., which can solve the problem that large-diameter pipelines cannot be tested at the factory, complicated operating procedures, and a small number of components, etc. problems, to achieve the effect of high degree of automation, strong on-site operability, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

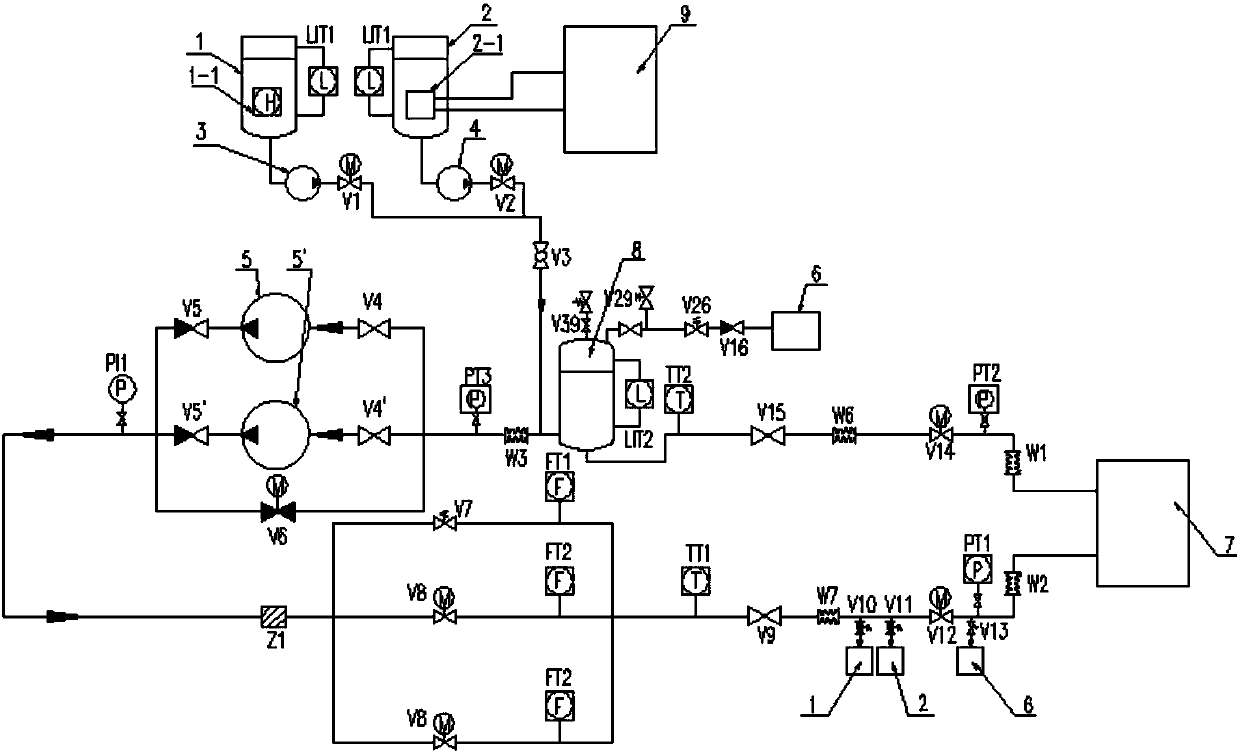

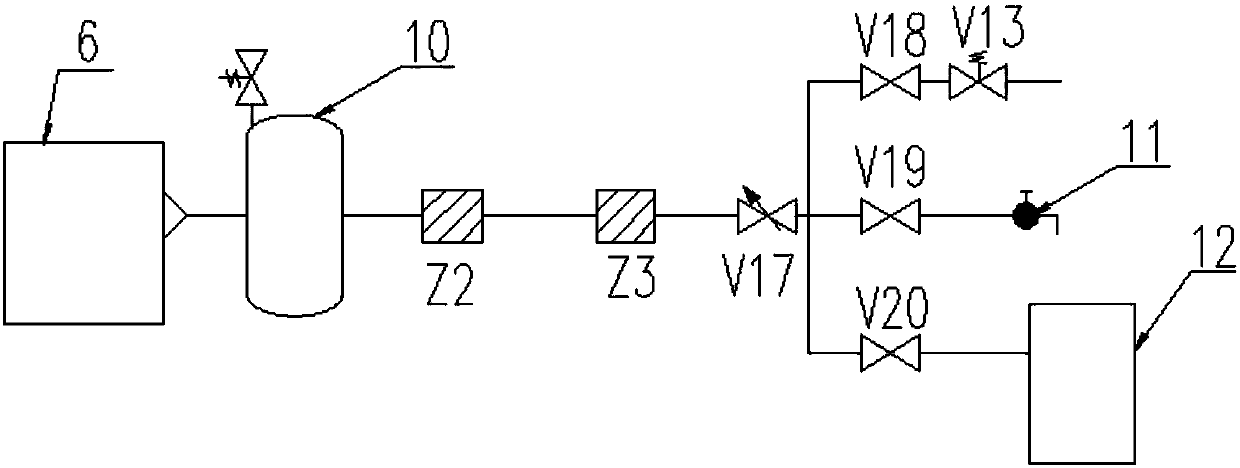

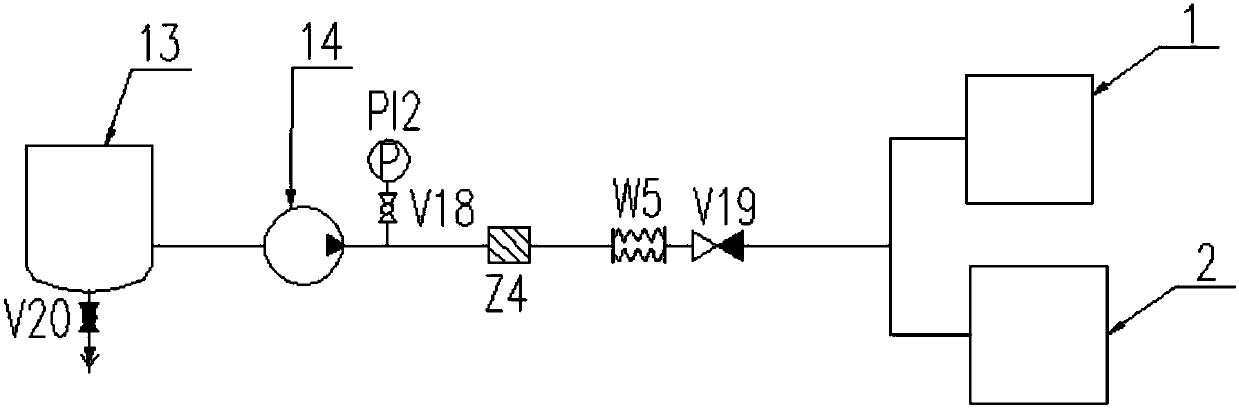

[0037] On the one hand, the present invention provides a cooling and heating alternate testing device for a converter valve cooling system, such as Figure 1 to Figure 3 As shown, including water supply system, main circulation system and air compressor, where:

[0038] The water supply system includes a hot water tank 1 and a cold water tank 2 connected in parallel. The water outlets of the hot water tank 1 and the cold water tank 2 pass through the first supplementary water pump 3, the first electric valve V1, the second supplementary water pump 4, and the second electric valve respectively. V2 is connected to the water inlet of the main circulation system;

[0039] The main circulation system includes the main circulation pump 5, the main filter Z1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com