Preparation method for inverted trapezoidal section photoresist mask on large-area glass substrate

A glass substrate, large-area technology, applied in photoengraving process coating equipment, photosensitive material processing, semiconductor/solid-state device manufacturing, etc., can solve the problem that the image reversal process cannot use the inverted trapezoidal cross-section photoresist mask, etc. , to achieve the effect of easy promotion, good repeatability, and avoidance of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

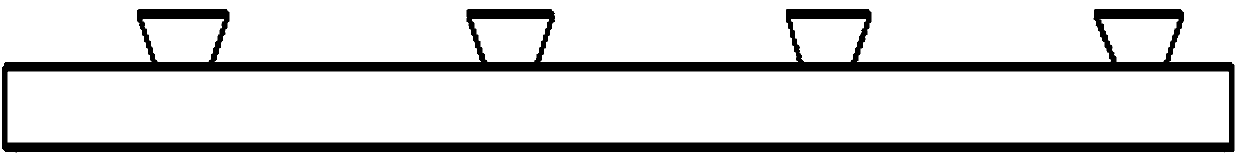

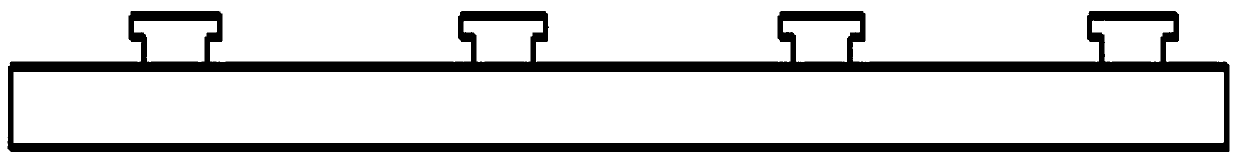

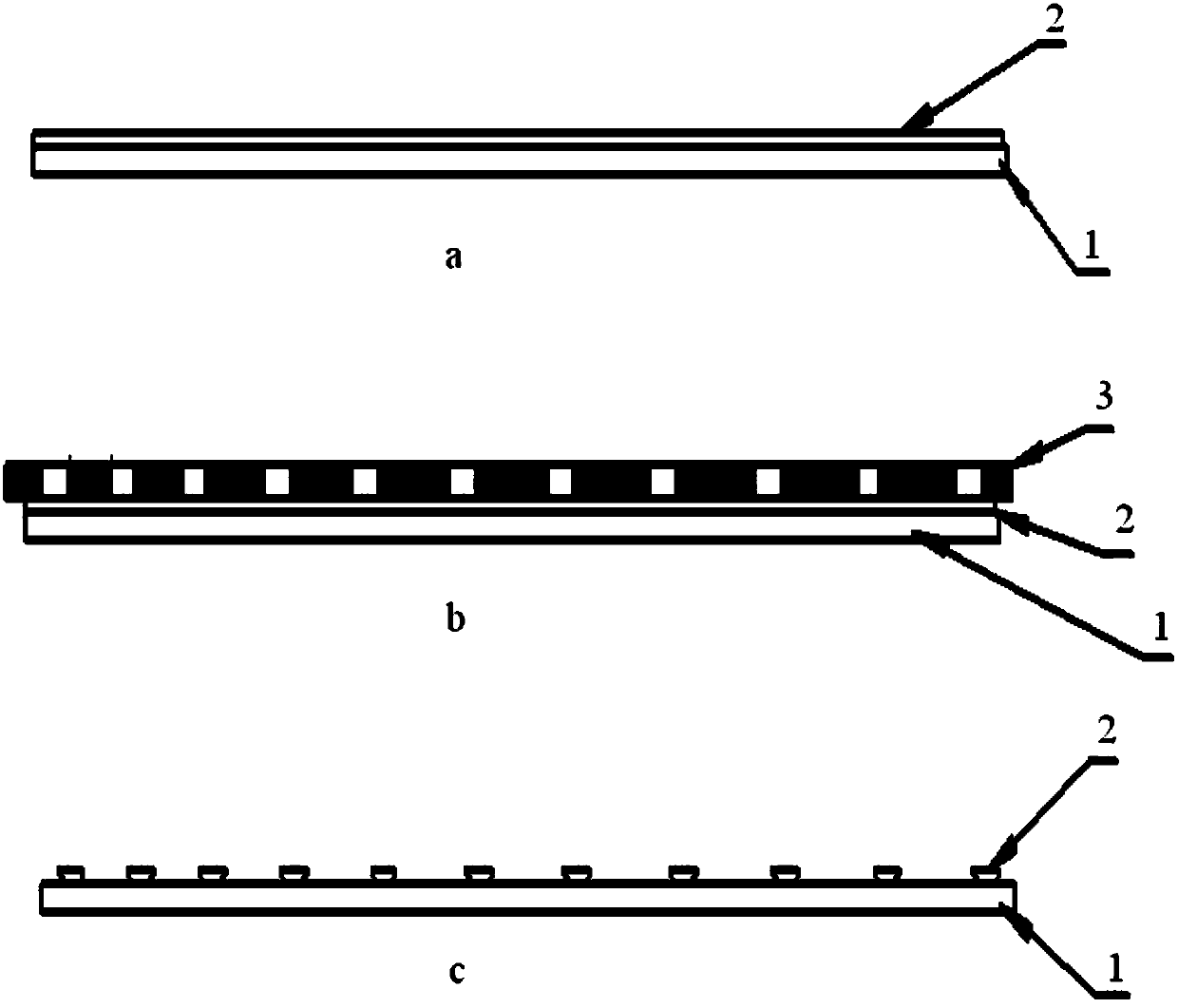

[0038] Example 1: Combining image 3 Illustrate the preparation method of the inverted trapezoidal section photoresist mask on a kind of large-area glass substrate provided by the present invention:

[0039] 1) Cleaning the large-area glass substrate 1 .

[0040] 2) Spin-coat AZ5214 photoresist 2 on the surface of a large-area glass substrate 1;

[0041] Spin-coat the photoresist 2 with a coater at a speed of 2500 rpm, spin-coat the AZ5214 reverse photoresist 2 on the large-area glass substrate 1 for 10 seconds, and then bake it in an ordinary oven at 60°C Bake large-area glass substrates for 1 30 minutes, and samples such as image 3 Shown in a.

[0042] 3) Expose the photoresist plate 3 with the pattern in close contact with the photoresist 2 on the surface of the large-area glass substrate 1, and the exposure time is 6 seconds. After completion, the sample is as follows: image 3 Shown in b.

[0043]4) Bake the exposed large-area glass substrate 1 in a common oven at a...

Embodiment 2

[0047] 1) Cleaning the large-area glass substrate.

[0048] 2) Spin-coat AZ5214 photoresist on the surface of a large-area glass substrate;

[0049] Spin-coat the photoresist with a coater at a speed of 1000 rpm, spin-coat the AZ5214 reverse photoresist on a large-area glass substrate for 10 seconds, and then bake the large-area in a common oven at 60°C 20 points for a glass substrate.

[0050] 3) Expose the photolithographic plate with the pattern in close contact with the photoresist of the large-area glass substrate, and the exposure time is 6 seconds.

[0051] 4) Baking the exposed large-area glass substrate in a common oven at a temperature of 115° C. for 6 minutes.

[0052] 5) The photoresist spin-coated on the surface of the large-area glass substrate after baking is subjected to flood exposure under an exposure machine, and the exposure time is 55 seconds.

[0053] 6) The large-area glass substrate after flood exposure was developed in AZ5214 developer solution for ...

Embodiment 3

[0055] 1) Cleaning the large-area glass substrate.

[0056] 2) Spin-coat AZ5214 photoresist on the surface of a large-area glass substrate;

[0057] Spin-coat the photoresist with a coater at a speed of 4000 rpm, spin-coat the AZ5214 reverse photoresist on a large-area glass substrate for 10 seconds, and then bake the large-area in a common oven at 80°C 40 points for glass substrates.

[0058] 3) Expose the photolithographic plate with the pattern in close contact with the photoresist of the large-area glass substrate, and the exposure time is 10 seconds.

[0059] 4) Baking the exposed large-area glass substrate in a common oven at a temperature of 130° C. for 10 minutes.

[0060] 5) The photoresist spin-coated on the surface of the large-area glass substrate after the second baking is subjected to flood exposure under an exposure machine, and the exposure time is 30 seconds.

[0061] 6) The large-area glass substrate after flood exposure was developed in AZ5214 developer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com