Soft magnetic composite magnetic ring and preparation method therefor

A soft magnetic compound and magnetic ring technology, applied in the field of magnetoelectricity, can solve the problems of high Bs value, low cost, high magnetic permeability, etc., and achieve the effect of excellent DC superposition performance and high Bs value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Raw materials: 120 mesh to 200 mesh sendust powder, manganese zinc ferrite powder with a magnetic permeability of 3000.

[0020] Preparation of ferrite magnetic ring: manganese zinc ferrite powder with magnetic permeability of 3000, sintering temperature of 1340°C, standard sintering curve, and the size of the prepared magnetic ring is 25*15*6.

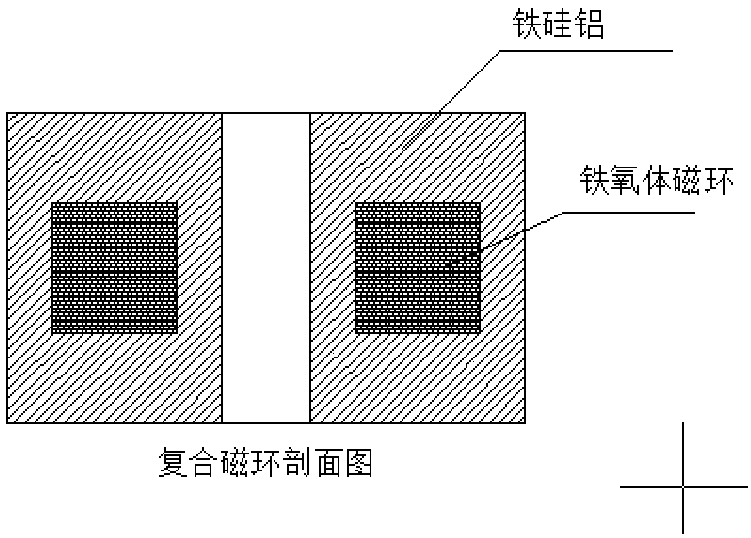

[0021] Molding: Put 120-mesh to 200-mesh sendust aluminum powder into passivation treatment, put it into the H28*12*10 mold, according to the ratio of the height dimension of the mold cavity filler to the thickness dimension of the pressed blank (charging ratio) 1.4, put 2.8mm thick sendust powder; then place the sintered ferrite magnetic ring on the sendust powder; then use sendust powder to scrape the mold cavity. Press 20T pressure per square centimeter, and the finished product density is controlled at 5.5g / cm 3 .

[0022] Heat treatment: The pressed composite magnetic ring is heat treated in an argon protective atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Power loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com