A cooling tray device and wafer etching equipment

A tray and chip loading technology, applied in the field of microelectronics, can solve the problems of etching process failure, affecting the performance of plasma processing equipment, small gas flow, etc., and achieve the effect of significant heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

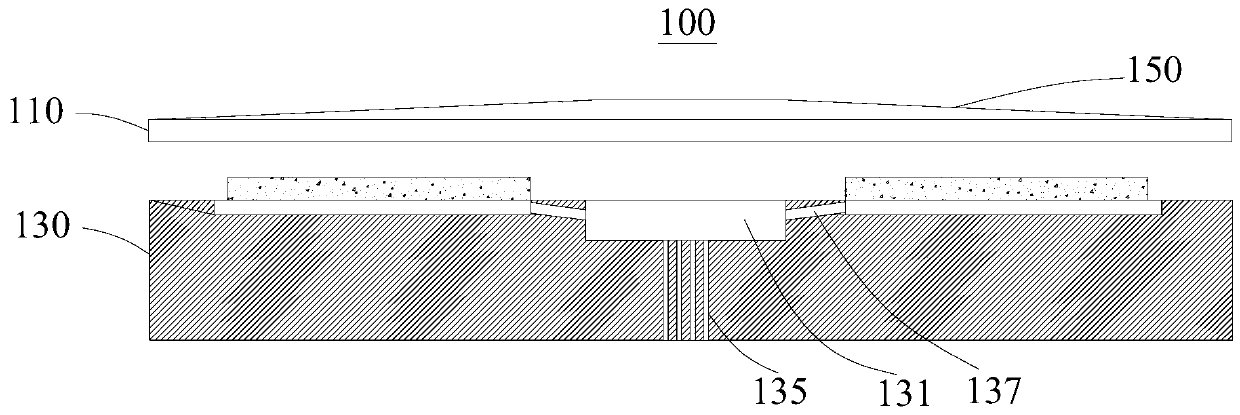

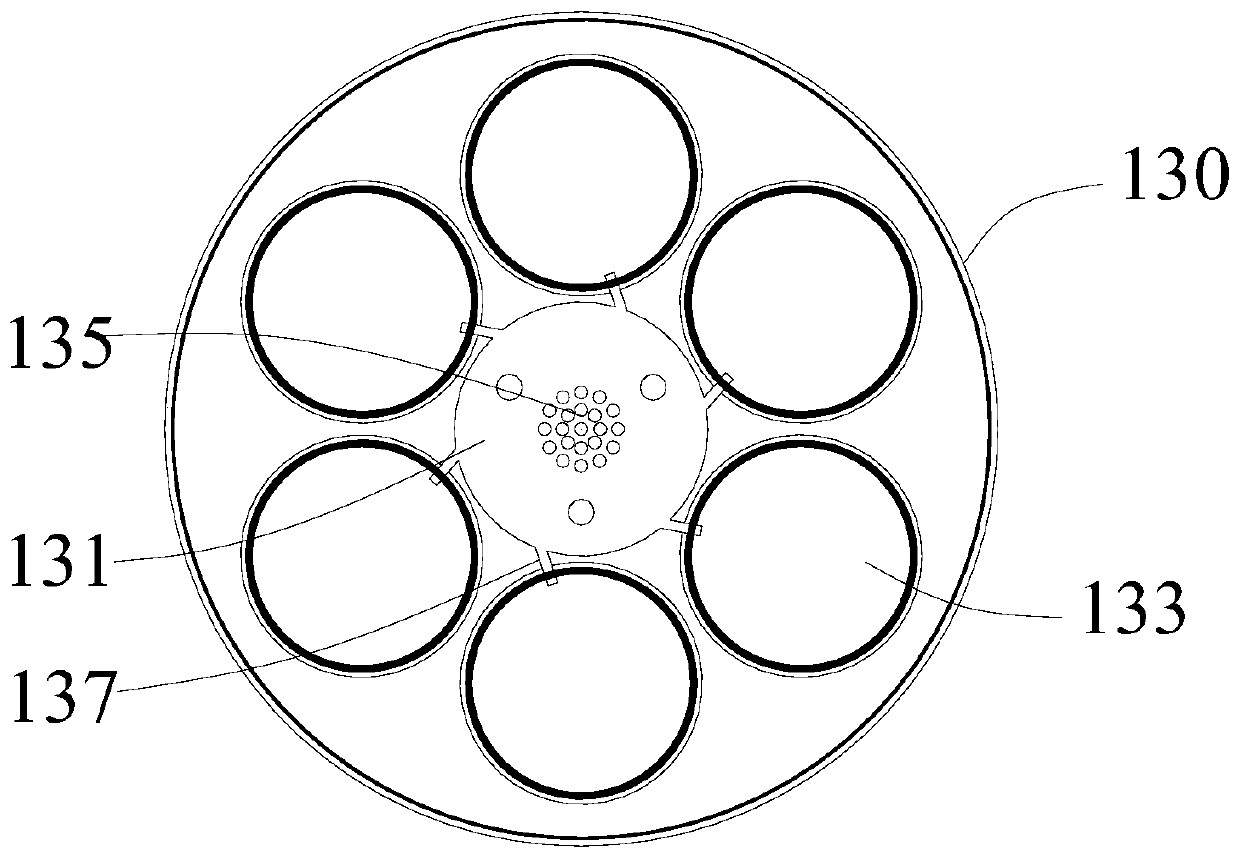

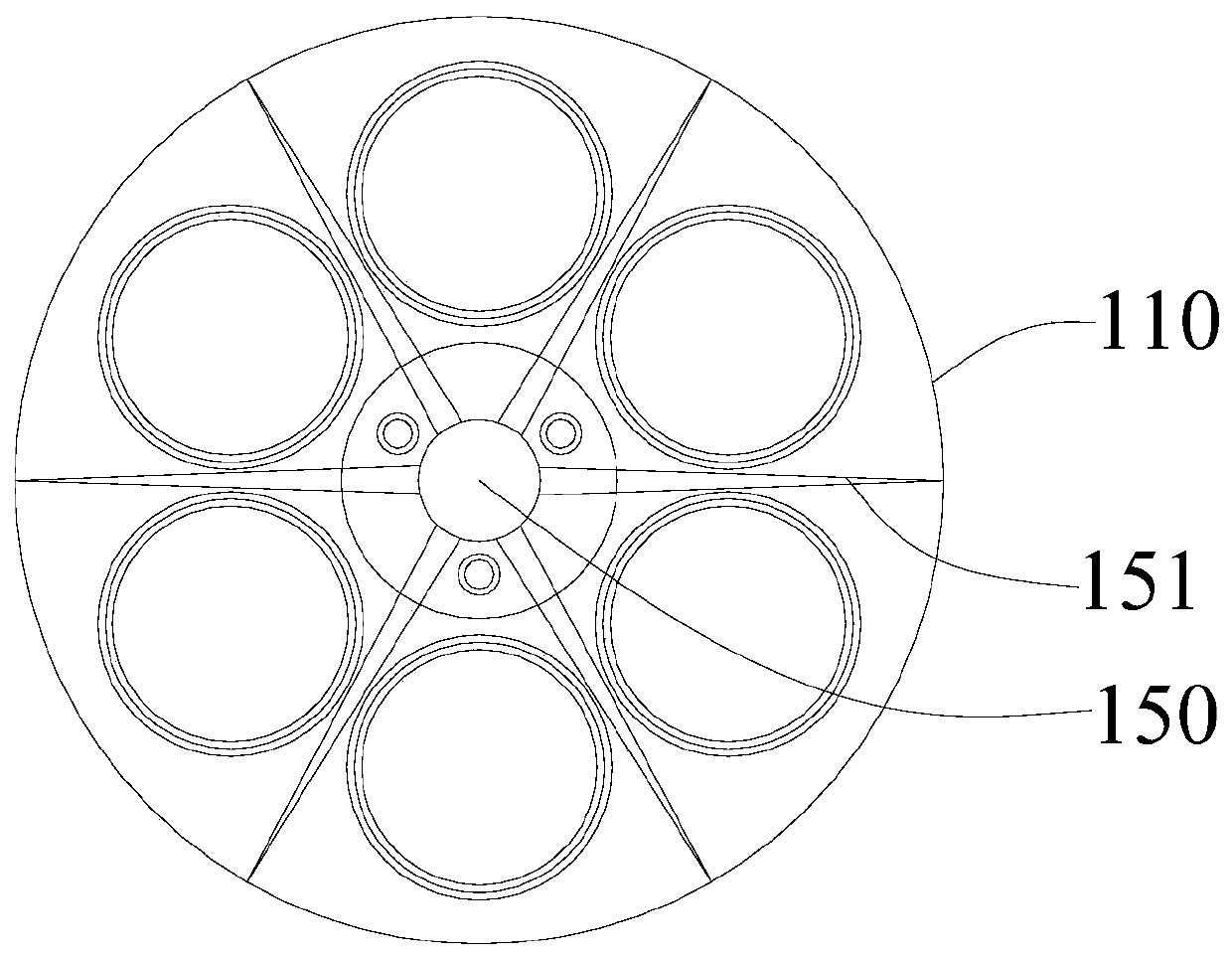

[0034] see in conjunction Figure 1 to Figure 3 , this embodiment provides a heat dissipation tray device 100, which is installed on a stage (not shown) and used for loading wafers. The heat dissipation tray device 100 includes a cover plate 110, a tray 130 and a reinforcement structure 150. The tray 130 is used for The cover plate 110 is detachably mounted on the tray 130 and is detachably connected to the object platform. The reinforcing structure 150 is fixedly connected to the cover plate 110 for strengthening the cover plate 110 .

[0035] In this embodiment, the cover plate 110 is made of alumina ceramics, and the content of alumina in the alumina ceramics is 99%. The alumina ceramics with this proportion have a larger coefficient of thermal expansion and stronger heat bearing capacity.

[0036] The tray 130 is provided with a ventilation groove 131 and at least one chip loading groove 133, the chip loading groove 133 is used to accommodate the wafer, and the bottom of ...

no. 2 example

[0055] see Figure 5 , this embodiment provides a wafer etching device 200, including the device housing 210, the stage 230 and the cooling tray device 100, wherein the basic structure and principle of the cooling tray device 100 and the technical effects produced are the same as those of the first embodiment Similarly, for brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0056] The heat dissipation tray device 100 includes a cover plate 110 and a tray 130 , and the cover plate 110 is detachably covered on the tray 130 . The tray 130 is provided with a ventilation groove 131 and at least one chip loading groove 133, the chip loading groove 133 is used to accommodate the wafer, and the bottom of the ventilation groove 131 has a cooling gas through hole 135 for passing in cooling gas, The bottom of the chip loading groove 133 has an air intake channel 137 , and the ventilation groove 131...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com