Stress-prevention tool for insulation wire

A technology for insulated wires and tools, applied in the direction of connecting/terminating cables, etc., can solve problems such as reduction, oxidation and burning, and achieve the effect of smooth and smooth turning arc, stress relief, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

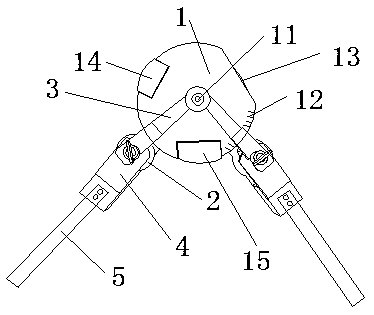

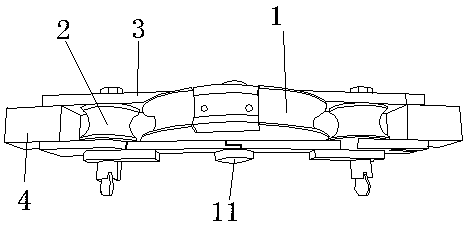

[0020] Such as figure 1 with figure 2 As shown, a kind of insulated wire stress-resisting tool, which includes a runner 1, a handle, the runner 1 is provided with a central axis 11, a notch, two handles are provided, and the handle is also provided with a rotating bracket 3, a handle bracket 4, Handle 5, rotating pinch wheel 2, handle is rotatably connected with central axis 11 of runner 1 by rotating bracket 3, and rotating bracket 3 is connected with handle bracket 4, and rotating pinch wheel 2 is located at the junction of rotating bracket 3 and handle bracket 4. The insulated conductor is inserted between the runner 1 and the rotating pinch wheel 2 through the notch of the runner 1 , and the handle is turned to make the runner 1 and the rotary pinch wheel 2 clamp the insulated conductor and bend the insulated conductor along the runner 1 .

[0021] Wherein, the runner 1 is provided with an angle scale 12, and the angle scale 12 is depicted so that different molds with di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com