Double-stator superconducting brushless doubly-fed wind turbine

A wind turbine and double stator technology, applied in the direction of winding conductive materials, electromechanical devices, electrical components, etc., can solve the problems of complex installation and low reliability, and achieve the effect of high space efficiency, high reliability, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

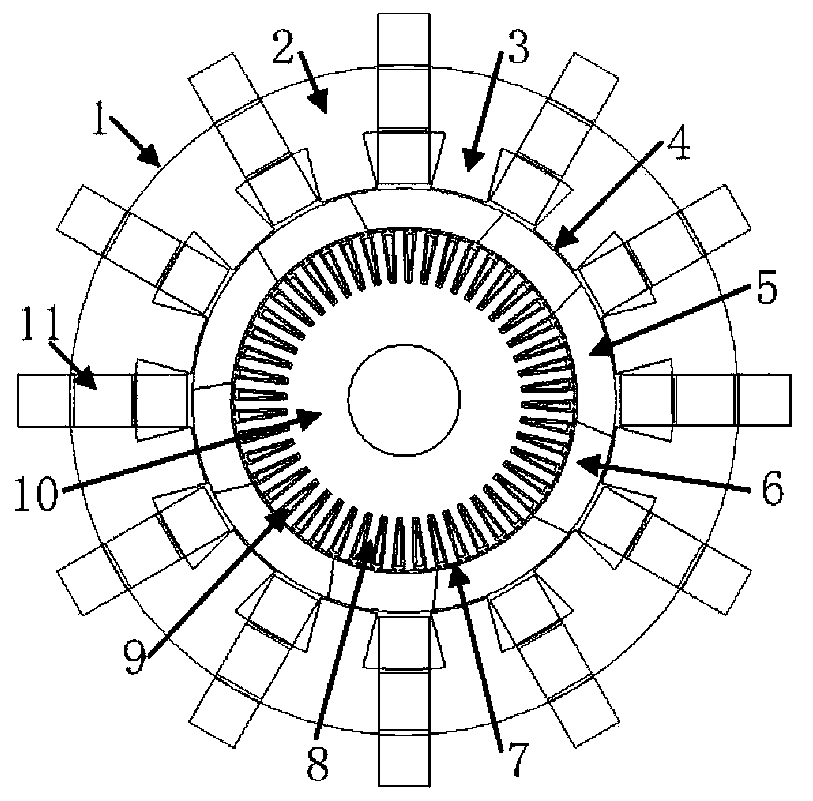

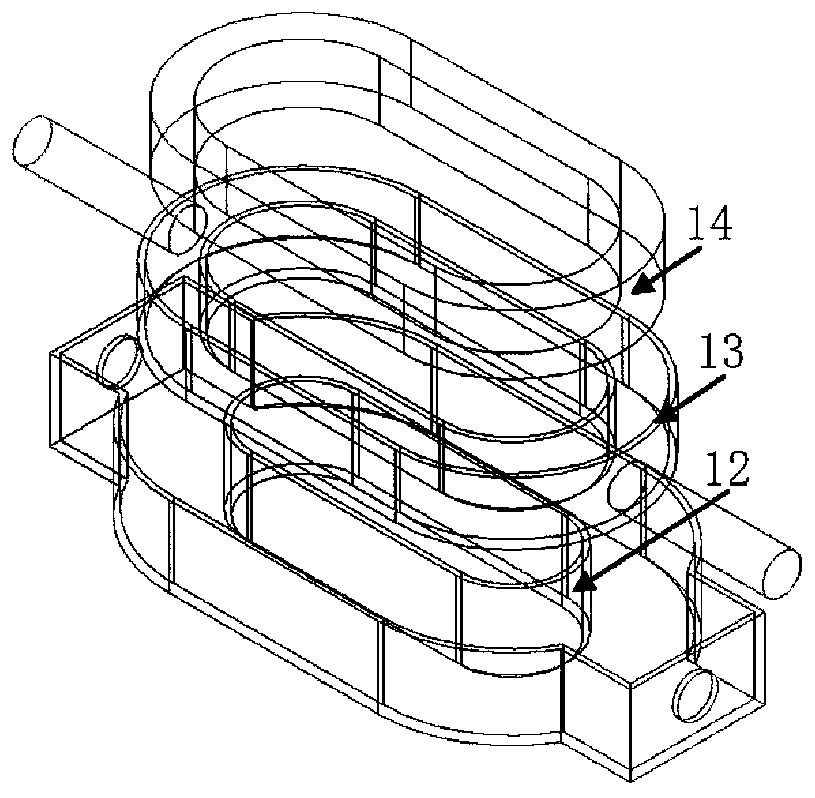

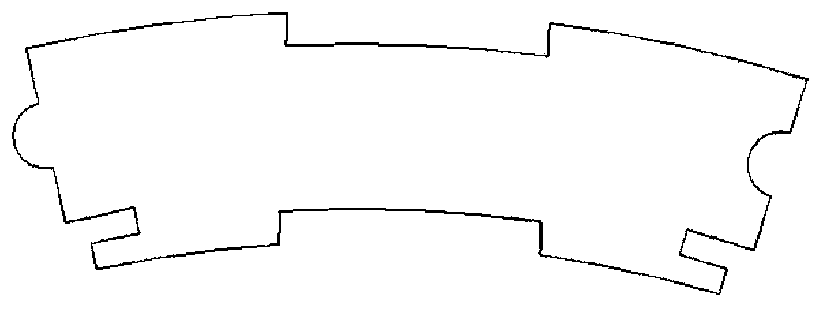

[0037] The double-stator superconducting brushless doubly-fed wind generator of the present invention includes two stators and a reluctance rotor, and the three are arranged concentrically from inside to outside or coaxially from left to right. The technical solution is now explained in the form of concentric arrangement: the three components are called the inner stator, rotor and outer stator in turn from the inside to the outside, there is an outer air gap between the outer stator and the rotor, and an inner air gap between the inner stator and the rotor ; The outer stator includes an outer stator yoke, an outer stator tooth, a racetrack-shaped Dewar bottle and an annular full-distance distribution superconducting control winding; the superconducting control winding is placed in the Dewar bottle; the outer stator The gaps between the teeth form the outer stator slots, each outer stator slot corresponds to a Dewar bottle, and the Dewar bottle surrounds the outer stator yoke; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com