Bamboo stem biochar quantum dot modified Bi4Ti3O12 composite photocatalyst preparation and application

A technology of biological carbon and quantum dots, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, water/sludge/sewage treatment, etc., can solve the problem of low light energy utilization rate of photocatalytic materials , complex synthesis process, low photocatalytic efficiency, etc., to achieve the effect of enhancing binding force, improving stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of bamboo stem biocarbon quantum dots:

[0030] 3 g of bamboo stem powder was weighed and dispersed in 30 mL of deionized water, stirred evenly at room temperature to form a mixed solution, and then transferred into a 50 mL autoclave and heated at 200 °C for 24 h. After the reaction product was naturally cooled, the supernatant was centrifuged and dialyzed in a dialysis bag (molecular weight 8000-14000) for 24 h to obtain a bamboo stem biocarbon quantum dot solution, which was freeze-dried to obtain bamboo stem biocarbon quantum dots.

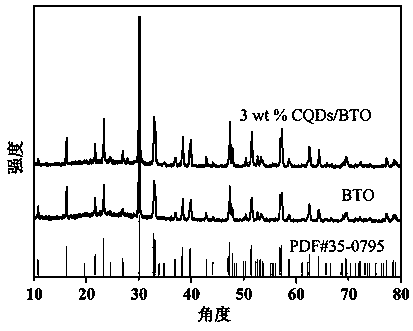

[0031] (2) Bi 4 Ti 3 o 12 Preparation of materials:

[0032] 0.93 g bismuth oxide and 0.244 g P 25 Fully grind evenly, put into tube furnace / muffle furnace, take 144 min from 30-800 ℃, calcine at 800 ℃, calcine for 3 h, cool naturally to get Bi 4 Ti 3 o 12 Material.

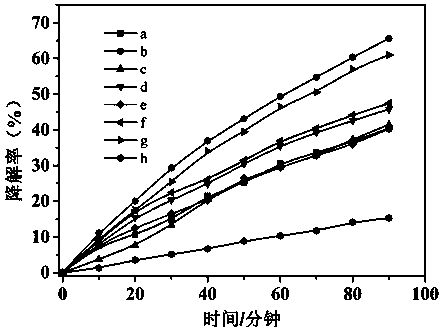

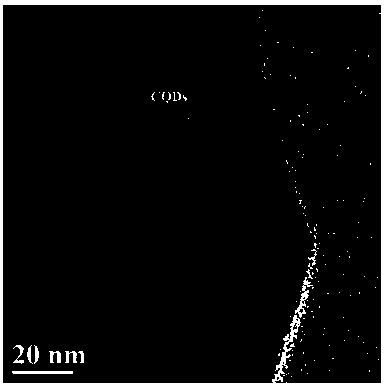

[0033] (3) Bamboo stem biocarbon quantum dots modified Bi 4 Ti 3 o 12 Preparation of composite photocatalyst:

[0034] Weigh 0.001 g of bamboo s...

Embodiment 2

[0038] (1) Preparation of bamboo stem biocarbon quantum dots:

[0039] 3 g of bamboo stem powder was weighed and dispersed in 30 mL of deionized water, stirred evenly at room temperature to form a mixed solution, and then transferred into a 50 mL autoclave and heated at 200 °C for 24 h. After the reaction product was naturally cooled, the supernatant was centrifuged and dialyzed in a dialysis bag (molecular weight 8000-14000) for 24 h to obtain a bamboo stem biocarbon quantum dot solution, which was freeze-dried to obtain bamboo stem biocarbon quantum dots.

[0040] (2) Bi 4 Ti 3 o 12 Preparation of materials:

[0041] 0.93 g bismuth oxide and 0.244 g P 25 Fully grind evenly, put into tube furnace / muffle furnace, take 144 min from 30-800 ℃, calcine at 800 ℃, calcine for 3 h, cool naturally to get Bi 4 Ti 3 o 12 Material.

[0042] (3) Bamboo stem biocarbon quantum dots modified Bi 4 Ti 3 o 12 Preparation of composite photocatalyst:

[0043] Weigh 0.003 g of bamboo s...

Embodiment 3

[0047] (1) Preparation of bamboo stem biocarbon quantum dots:

[0048] Weigh 3 g of bamboo stem powder and disperse it in 30 mL of deionized water, stir evenly at room temperature to form a mixed solution, then transfer it into a 50 mL autoclave and heat at 200 °C for 24 h. After the reaction product was naturally cooled, the supernatant was centrifuged and dialyzed in a dialysis bag (molecular weight: 8000-14000) for 24 hours to obtain a bamboo stem biocarbon quantum dot solution, which was freeze-dried to obtain bamboo stem biocarbon quantum dots.

[0049] (2) Bi 4 Ti 3 o 12 Preparation of materials:

[0050] 0.93 g bismuth oxide and 0.244 g P 25 Fully grind evenly, put into tube furnace / muffle furnace, take 144 min from 30-800 ℃, calcine at 800 ℃, calcine for 3 h, cool naturally to get Bi 4 Ti 3 o 12 Material.

[0051] (3) Bamboo stem biocarbon quantum dots modified Bi 4 Ti 3 o 12 Preparation of composite photocatalyst:

[0052] Weigh 0.009 g of bamboo stem bioc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com