Novel combined water cooling die

A combined, water-cooled technology, applied in the direction of molds, cores, mold components, etc., can solve problems such as low mold life, easy corrosion at the bottom of the mold, and low product qualification rate, so as to improve equipment production capacity and speed up heat exchange. Efficiency, optimized metal quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

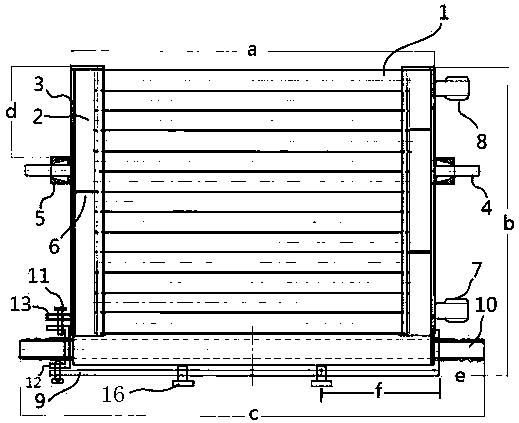

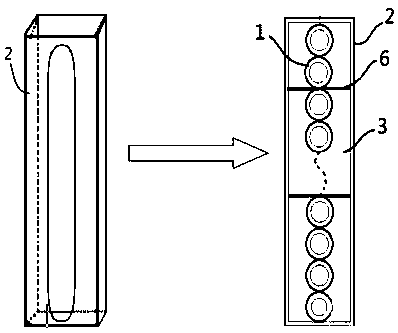

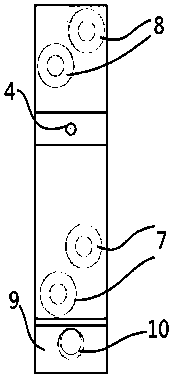

[0021] Water-cooling mold assembly: Stand the two side channels 2 with their backs facing each other, place several seamless steel pipes 1 in line from bottom to top, weld them together, weld two sets, and weld two sets of seamless steel pipes 1 Arranged in parallel, the two ends of the seamless steel pipe 1 penetrate into the cavity of the side channel 2 respectively by about 2-3mm, and the contact position between the seamless steel tube 1 and the side channel 2 is fully welded and sealed. Every 3-5 seamless steel pipes in the two side channels are flat-welded with a water barrier 6, and the water barriers in the left and right side channels are welded alternately, such as: welding a water barrier in the left side channel of the third steel pipe A water baffle plate is welded in the right channel of the sixth steel pipe, and a water baffle plate is welded in the left channel of the ninth steel pipe...and so on, so that the water flows from bottom to top according to the "S" c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com