Numerical control machine tool

A technology of CNC lathe and bed, which is applied in the direction of metal processing machinery parts, turning equipment, maintenance and safety accessories, etc. It can solve the problems of untimely debris disposal and the impact of processing debris, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

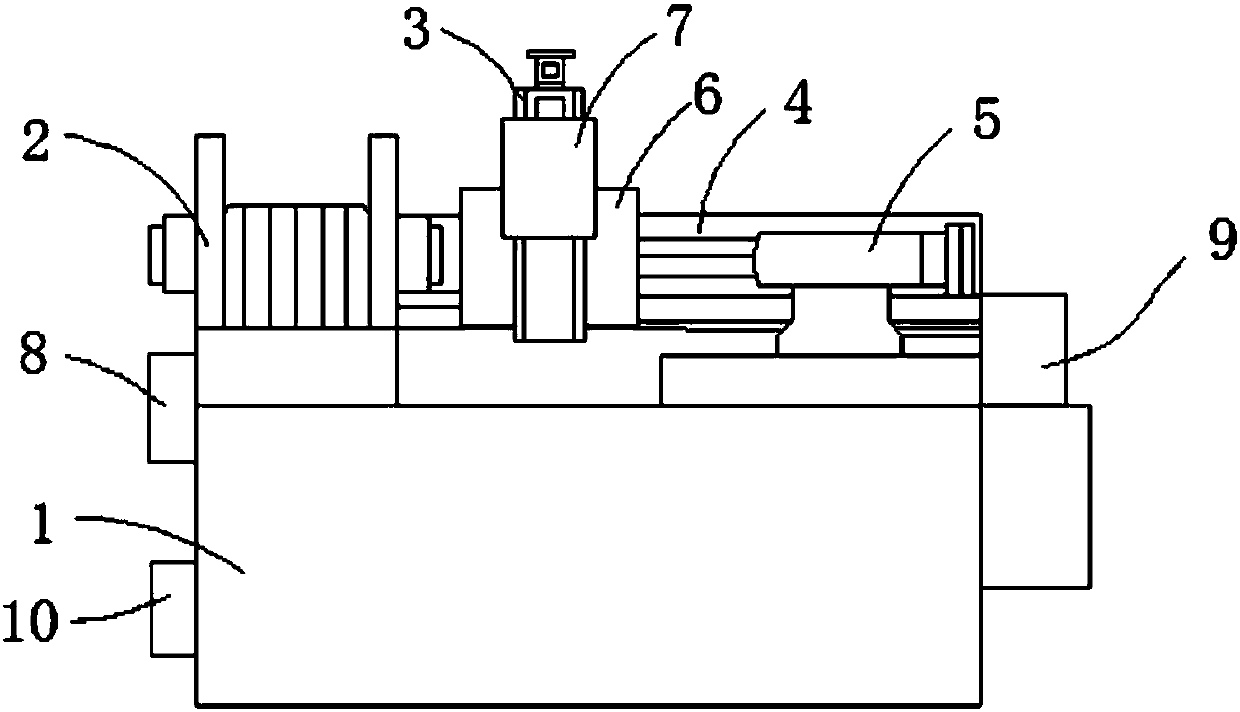

[0011] Such as figure 1 As shown, a chip removal CNC lathe includes a bed 1, a headstock 2, a Z-axis guide rail 3, an X-axis guide rail 4 and a tailstock 5, and the headstock 2 and the X-axis guide rail 4 are fixedly placed on the bed The upper end of the body 1, the X-axis guide rail 4 is on one side of the headstock 2, the X-axis guide rail 4 is equipped with a laterally movable X-axis feed table 6, and the Z-axis guide rail 3 is fixed on the On the X-axis feed table 6, the Z-axis guide rail 3 is equipped with a vertically movable Z-axis feed table 7, and the guide grooves of the X-axis guide rail 4 and the Z-axis guide rail 3 are all made of graphene. In this way, the tailstock 5 is placed on the side of the X-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com